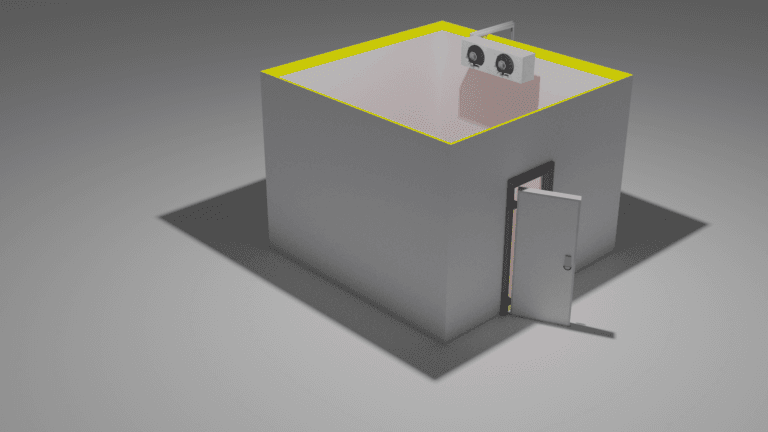

Introduction to Blast Freezer Room for Chicken and Poultry

Blast freezer rooms are specialized facilities designed to freeze chicken and poultry products rapidly. They play a critical role in the food industry by preserving freshness and extending shelf life.

- Purpose: These rooms are essential for maintaining product integrity. They rapidly lower the temperature of poultry products to inhibit bacterial growth and preserve nutritional value.

- Functionality: Utilises powerful fans and evaporators to circulate cold air efficiently, freezing products in minimal time.

- Benefits:

- Ensures food safety by minimizing time spent in the temperature danger zone.

- Maintains the texture and taste of chicken and poultry.

Effective use of blast freezer rooms can optimize storage and distribution processes.

Importance of Blast Freezer Rooms in the Poultry Industry

Blast freezers play a critical role in the poultry industry for numerous reasons:

- Quality Preservation: By chilling poultry swiftly, blast freezers maintain texture and taste, preventing ice crystal formation.

- Extended Shelf Life: Reducing bacterial growth, significantly prolongs the product’s shelf life.

- Economic Benefits: Minimising waste, contributes to economic efficiency, allowing for better inventory management.

- Safety Compliance: Meeting health regulations requires maintaining optimal storage conditions, which blast freezers facilitate.

- Energy Efficiency: Designed for rapid and consistent freezing, they consume less energy compared to traditional methods, aiding cost management.

How Blast Freezer Room Work

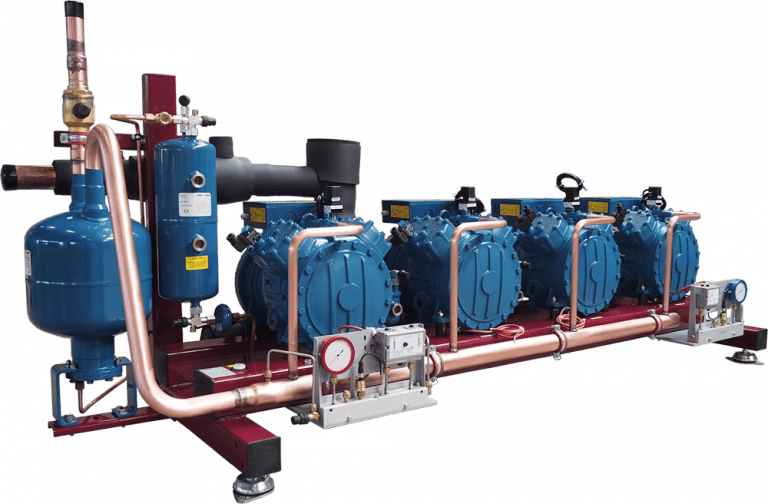

A blast freezer rapidly decreases the temperature of chicken and poultry by using intensely cold air circulation. The process relies on key components and steps:

- Evaporators: These units remove heat from the blast freezer, swiftly cooling the air.

- Powerful Fans: High-velocity fans distribute the chilled air evenly to all corners.

- Temperature Sensors: Integrated sensors maintain the designated freezing level.

- Control Systems: Automated systems manage the temperature and airflow.

- Rapid Freezing: The process minimizes ice crystal size, preserving meat quality.

By maintaining temperatures below -35°C, blast freezers ensure optimum texture, flavour, and longevity for frozen poultry products.

Key Features of a Blast Freezer Room

A blast freezer room is a specialized facility designed to rapidly freeze chicken and poultry products to preserve quality and safety. Key features include:

- Rapid Freezing Technology: Achieves ultra-low temperatures quickly, ensuring rapid freezing of meat products.

- Precise Temperature Control: Maintains consistent temperature settings, vital for optimal food preservation.

- Efficient Insulation: High-grade insulation materials keep the cold air inside, reducing energy consumption.

- Hygienic Design: Smooth, durable surfaces promote easy cleaning and prevent contamination.

- Customizable Shelving: Adjustable shelves or racks allow efficient storage of various poultry sizes.

- Advanced Air Circulation: Enhances freezing uniformity by distributing cold air evenly throughout the room.

- User-Friendly Controls: Easy-to-use interface for monitoring temperature and managing settings effectively.

Temperature Control and its Impact

Effective temperature control in a blast freezer room is crucial for maintaining poultry quality. It ensures chicken remains at an optimum temperature, preventing microbial growth.

- Quick Freezing: This process rapidly lowers the temperature, preserving the cellular structure and freshness.

- Consistent Temperature: Maintaining a steady low temperature minimizes thaw cycles, reducing spoilage risk.

- Energy Efficiency: Proper control decreases energy consumption, leading to cost savings and environmental benefits.

“Ensuring precise temperature control can significantly extend poultry shelf life, curtailing food waste and enhancing safety standards,” remark food safety experts.

By strictly monitoring temperatures, organizations safeguard poultry products’ nutritional value and taste.

Benefits of Blast Freezers for Chicken Preservation

Blast freezers present numerous advantages when it comes to preserving chicken.

- Rapid Freezing: They enable quick freezing, preventing large ice crystals from forming, thus maintaining chicken texture and flavour.

- Extended Shelf Life: By slowing bacterial growth, they extend the shelf life of chicken products significantly.

- Nutritional Retention: The nutritive qualities of the chicken are retained through minimal exposure to air and dehydration.

- Reduced Waste: They help in reducing waste caused by spoilage, ensuring a fresher product.

- Economic Efficiency: With longer storage durations, businesses can manage inventory more effectively, saving costs.

- Consistency and Quality: They ensure uniform freezing, maintaining high quality across batches.

Considerations When Setting Up a Blast Freezer Room

When setting up a blast freezer room for chicken and poultry, various factors should be considered to ensure efficiency and safety.

- Space and Location: Evaluate the available area to determine the appropriate size and layout of the room. Consider proximity to supply and processing areas.

- Insulation: Implement high-quality insulation to maintain consistent temperatures and reduce energy consumption.

- Ventilation: Ensure adequate airflow to prevent condensation and ice formation on poultry products.

- Temperature Control: Choose systems that offer precise temperature regulation and monitoring.

- Compliance: Adhere to local food safety and health regulations, ensuring the design and materials meet the required standards.

Maintaining Hygiene Standards in Blast Freezer Rooms

In a blast freezer room for chicken and poultry, upholding hygiene standards is crucial. Ensuring cleanliness involves several key practices:

- Regular Cleaning: Schedule regular cleaning of both the freezer itself and adjacent areas to prevent contamination.

- Sanitisation Procedures: Utilize effective sanitizing agents to kill bacteria, especially in high-contact surfaces.

- Personal Hygiene: Ensure personnel maintain strict personal hygiene, using gloves and hairnets.

- Temperature Monitoring: Regularly check and document temperatures to ensure consistent conditions.

- Inspecting Products: Conduct frequent inspections of poultry products for quality assurance.

Maintaining hygiene prevents spoilage, enhances safety, and keeps products compliant with health regulations.

Overall, diligent hygiene practices are essential in maintaining safety standards.

Common Challenges and Solutions

Blast freezer rooms for chicken and poultry present unique challenges.

- Temperature Control: Maintaining consistent low temperatures can be difficult. Investing in high-quality insulation and temperature monitoring systems helps ensure stability.

- Moisture Management: Controlling humidity is critical to prevent spoilage. Installing a dehumidification system mitigates this risk effectively.

- Energy Efficiency: High energy consumption increases costs. Implementing energy-efficient technologies, like variable frequency drives (VFDs), can significantly reduce power usage.

- Space Utilisation: Limited space may hinder operations. Optimizing floor plans and using adjustable shelving maximizes capacity.

“Efficient management of these aspects ensures optimal functioning of blast freezer rooms, preserving poultry quality and extending shelf life.”

Ensuring these strategies are in place leads to better operational efficiency and product quality.