Blast freezer technology represents a significant advancement in the field of food preservation, enabling the extension of shelf life for a wide variety of perishable products. This method utilises extremely cold air, typically ranging between -18°C to -40°C, to rapidly lower the temperature of food items, substantially slowing down microbial growth and enzymatic reactions that contribute to food spoilage.

Key features of blast freezers include:

- High-velocity air circulation: By circulating air at high speeds, blast freezers ensure quick and uniform freezing, preventing the formation of large ice crystals within the cellular structure of food, which can compromise texture and nutritional value.

- Temperature control: Precision temperature controls allow for maintaining optimal conditions tailored to different types of food products, from delicate fruits to dense meats.

- Efficiency: Although they consume a high amount of energy during operation, blast freezers actually contribute to energy savings in the long run due to the preservation of food at peak quality, reducing wastage.

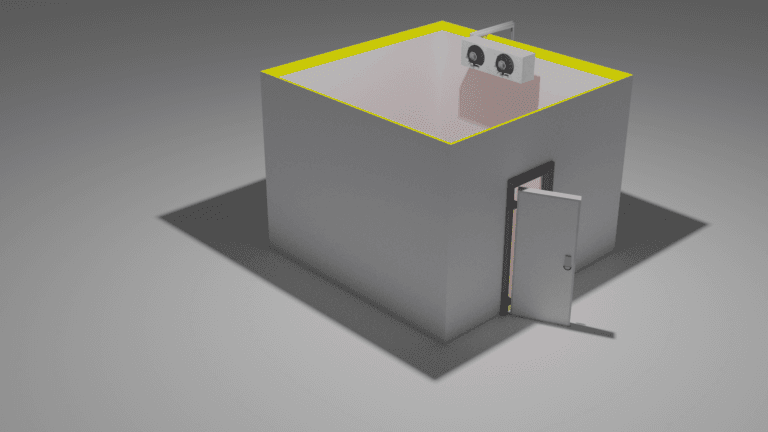

- Scalability: Designed to accommodate varying volumes of food, from small-scale operations to industrial facilities, blast freezers can be tailored to meet the demands of any business size.

Unlike traditional freezing methods, blast freezing ‘locks in’ the freshness of products immediately after harvesting or processing, thereby retaining food’s original flavour, texture, and nutritional content more effectively. Moreover, this rapid freezing process ensures that the food products reach the ‘safe zone’, below -18°C, quickly enough to deter the growth of harmful bacteria.

Industries that widely use blast freezing technology include seafood, meat, ready-to-eat meals, bakery and dairy products, and within the pharmaceutical sector for preservation of temperature-sensitive products. The adaptability and efficiency of blast freezers make them a revolutionary tool in maintaining the integrity of products throughout the supply chain from production to the consumer.

Understanding the Basics: What is a Blast Freezer?

A blast freezer, also known as a shock freezer, is an essential piece of equipment in the food preservation industry designed to rapidly bring down the temperature of food products. This type of freezer operates by circulating extremely cold air across the food items, typically at temperatures ranging from -18°C to -40°C. The principle behind its operation is to quickly freeze the food before large ice crystals can form, which would otherwise damage the cellular structure during slower freezing processes.

Here’s how a blast freezer achieves its goal:

- Fast Freezing: By subjecting food to intense cold air, the time taken to reach the core of the product and freeze it is significantly reduced.

- Temperature Control: Blast freezers are equipped with precise temperature controls to maintain the necessary cold environment for effectively preserving the product.

- Reduction of Ice Crystals: The rapid freezing helps form very small ice crystals, which are less damaging to the cellular integrity of food, maintaining texture and flavour.

- Efficiency: Energy is used more efficiently as the time the freezer operates at its most intense stage is shorter than traditional freezers.

- Improved Shelf Life: The decreased enzymatic and bacterial activity due to the extreme cold extends the shelf life of the food.

By using a blast freezer, food manufacturers and processors ensure that the quality, nutritional value, and safety of the frozen products are preserved until they are thawed for consumption. This is particularly essential for industries where the quality at the point of defrost is crucial, such as in catering and food service businesses. With proper usage, a blast freezer can be a game-changer for businesses looking to maintain high standards in food quality and safety.

The Science of Shelf Life Extension in Frozen Foods

Achieving an extended shelf life in frozen foods is delicately rooted in the principles of food preservation and the innovative use of blast-freezing technology. When food is frozen quickly, the size of produced ice crystals is smaller, causing less damage to cell walls and better retaining the texture and nutritional value of the food. The faster the freezing process, the closer the result mirrors the food’s original state upon thawing.

Blast freezing systems capitalize on this science by exposing food products to extremely low temperatures at a rapid rate. This quick-freeze method dramatically slows down the enzymatic processes and microbial activity that typically lead to decay, thereby extending the food’s shelf life significantly. Key scientific elements include:

- Cryopreservation: A method that employs very low temperatures to preserve the structural integrity and functionality of cells in food items.

- Microbial Growth Inhibition: Microorganisms like bacteria and fungi are the primary cause of spoilage. Rapid freezing reduces the water available for microbial growth, thus inhibiting their proliferation.

- Enzymatic Activity Reduction: Enzymes that can cause food quality to deteriorate are subdued in the blast-freezing process, maintaining the sensory attributes of frozen food.

- Oxidation Minimization: Blast freezers can also minimize oxidation by freezing food before significant oxidation can occur, which helps preserve taste, color, and nutritional value.

Controlled atmosphere packaging can complement the freezing process. This involves modifying the mix of gases in the packaging (typically reducing oxygen) to further reduce oxidation and spoilage rates.

Research and development are continuous, with efforts focused on improving freezer efficiency, customizing freeze cycles for different types of food, and integrating smart technology for optimal preservation conditions. Scientists and engineers are constantly striving to refine these systems, ultimately contributing to a more sustainable and resilient food supply chain.

Comparing Traditional Freezing Techniques with Blast Freezer

Traditional freezing methods and blast freezing are both pivotal in the food preservation industry, yet they function on different principles and with varied outcomes on the quality and shelf life of food products.

- Speed of Freezing: Traditional freezing typically involves gradually bringing the temperature of the food down in a home freezer or a commercial refrigeration unit, which can take several hours. In contrast, blast freezing rapidly cools food by circulating extremely cold air across it, achieving target temperatures in minutes.

- Formation of Ice Crystals: The slow freezing process of traditional methods allows large ice crystals to form within the cellular structure of food, which can lead to cellular damage and deterioration in texture and flavor upon thawing. Blast freezing, due to its rapidity, creates much smaller ice crystals, minimizing cellular damage and thus preserving the texture and integrity of the food better.

- Energy Efficiency: Blast freezers are designed for efficiency and can handle larger quantities of food at a time, potentially reducing energy consumption per kilogram of product frozen. Traditional methods may use less energy at a time but are less efficient when considered in terms of energy per volume of food processed.

- Shelf Life Extension: The shelf life of blast-frozen products is generally longer due to the reduced enzymatic and bacterial activity from the quicker reduction in temperature. Traditional slow freezing allows some bacterial activity to continue before freezing completely, which can reduce the potential shelf life.

- Product Quality: Generally, blast freezing helps maintain the quality of the food better as compared to traditional freezing; it greatly reduces moisture loss (dehydration) and preserves the food’s original flavor, aroma, and nutritional content.

In summary, blast freezing holds distinct advantages over traditional freezing techniques due to its quick freezing time, energy efficiency, superior preservation of food quality, and enhanced extension of shelf life.

The Role of Temperature and Airflow in Blast FreezerEfficiency

Blast freezing is a rapid cooling method employed in the food industry to preserve the quality and extend the shelf life of perishable products. Achieving high efficiency in blast freezing necessitates the meticulous control of temperature and airflow.

Temperature

The temperature inside a blast freezer is a critical factor, as the goal is to reduce the temperature of products to -18°C or lower as quickly as possible. Rapid freezing is essential to minimise the formation of large ice crystals within the cellular structure of food, which can damage its texture and quality.

- Very low temperatures facilitate the quick transition of water to ice, inhibiting bacterial growth.

- The faster the freeze, the smaller the ice crystals, preserving the cell structure and hence the quality of the food.

Airflow

Efficient airflow is equally important to temperature control during blast freezing. It removes the heat from the surface of the product by replacing the warm air with colder air.

- Uniform airflow ensures that all parts of the product reach the desired low temperature at the same rate.

- High-velocity air streams lead to faster heat transfer, which is crucial for products with high moisture content or those packaged in layers.

- Optimising the direction and velocity of airflow can prevent insulating layers of warmer air from forming around the product.

Both temperature and airflow need to be manipulated with precision to prevent thermal shock and dehydration of the food, which can occur if the freezing process is too abrupt or uneven. Proper management of these elements within blast freezer systems is essential for maintaining the nutritional value, texture, and flavor of frozen products, making them practically indistinguishable from their fresh counterparts once thawed.

Microbial Activity and Enzymatic Reactions in Blast Frozen Products

Blast freezing is a rapid cooling method that significantly slows down the biochemical processes responsible for food spoilage and quality degradation. When foods are subjected to blast freezing, the temperature drop is so rapid that it inhibits the growth and reproductive cycles of microorganisms that typically lead to food decomposition.

- Microbial activity, such as that from bacteria, yeasts, and molds, requires specific environmental conditions to thrive, including temperature, pH, and moisture. Blast freezers swiftly reduce the temperature to levels where microbial metabolism is too slow to cause spoilage or foodborne illnesses.

- In addition to suppressing microbial growth, blast freezing also hampers the action of enzymes within food products. Enzymes are biological catalysts that can lead to unfavourable changes such as oxidation, browning, and texture degradation. By quickly lowering the temperature, the structural integrity of enzymes is disrupted, effectively pausing their activity.

- The quick-freeze method of blast freezers forms smaller ice crystals compared to conventional freezing, which preserves cellular structures and reduces the opportunity for enzyme-triggered cell damage upon thawing.

- Foods with high water content are particularly sensitive to enzymatic reactions. Blast freezing ensures that the enzymatic processes are halted more abruptly than in traditional freezing methods, which allows better preservation of taste, texture, and nutritional value.

The effectiveness of blast freezing in inhibiting microbial and enzymatic reactions results in extended shelf life and safer food products. It diminishes the likelihood of spoilage and maintains the food’s quality from the point of freezing to the moment it reaches the consumer, making blast freezer systems a revolutionary tool in the food industry.

Nutritional Integrity and Quality Preservation in Blast Freezer

Blast freezing technology plays a crucial role in maintaining the nutritional integrity and quality of food products during preservation. Through the rapid freezing process, this method significantly minimizes the formation of large ice crystals, which are often responsible for cellular damage in food items. By preserving the cell structure, the textural quality, flavour, and nutritional value of the food are retained much more effectively than with traditional freezing methods.

Key benefits of blast freezing in nutrition and quality retention are:

- Rapid Cooling Rate: Blast freezers achieve very low temperatures at an accelerated pace, thus swiftly crossing the crucial temperature zone between -1°C to -5°C, where the most significant crystal formation occurs. The speed of this process ensures that cells are less disturbed and that much of the product’s original quality is maintained.

- Minimal Drip Loss: When defrosting occurs, foods that have been blast-frozen typically exhibit less drip loss compared with slow-frozen foods. This means that the juices, which contain essential nutrients and flavors, are better retained.

- Better Nutrient Retention: Vitamins and minerals are better-preserved thanks to the quick freezing action. With less oxidative damage, antioxidants and other sensitive nutrients remain at higher levels in blast-frozen foods.

- Enhanced Shelf Life: Blast freezing extends the shelf life of food without the need for preservatives. This not only helps in retaining quality but also provides an avenue for food to be stored longer without significant decreases in nutritional value.

- Food Safety Considerations: By rapid freezing, blast freezers prevent the growth of bacteria and other pathogens. This is imperative in maintaining the safety of the food and ensuring it remains wholesome for consumption.

In conclusion, blast freezing presents a highly effective means of preserving the quality, safety, and nutritional value of a wide range of food products, thus positively revolutionizing the food preservation industry.

Case Studies: The Efficacy of Blast Freezers in Various Food Industries

Blast freezers are a critical component in the food industry, providing a rapid freezing method that preserves the quality of food products. Their impact is notable across various sectors within the food industry.

- Seafood Industry: One of the most compelling case studies comes from the seafood industry. Here, blast freezers have revolutionized the way fish and shellfish are preserved post-harvest or catch. Rapid freezing of seafood ensures that freshness is locked in, preventing bacterial growth and maintaining the food’s texture and taste. For example, a Japanese seafood company observed that implementing blast-freezing technology allowed them to extend the shelf life of sushi-grade tuna while preserving its sashimi-like quality for international shipping.

- Meat and Poultry: In the meat and poultry sector, blast freezers have significantly reduced microbiological risks by quickly bringing down the temperature of processed meat products. A 2019 case study showed that a North American meat processing plant employing blast freezing techniques managed to not only extend the shelf life of their products but also maximize the safety and quality of the meat, leading to an increase in customer satisfaction and a reduction in product returns due to spoilage.

- Bakery and Confectionery: The bakery industry has seen improved texture and taste retention in products subjected to blast freezing. A European bakery chain documented their transition to blast-freezing fresh-baked bread, resulting in a heightened ability to maintain a ‘just-baked’ freshness over an extended period. This facilitated a more efficient distribution process as well as a considerable reduction in food waste since products could be stored longer without compromising quality.

- Fruit and Vegetables: For producers of fruits and vegetables, blast freezing has allowed for seasonal products to be available year-round. A study involving a South American blueberry exporter showed that by blast freezing their harvest at peak ripeness, they maintained nutritional value and flavor while extending shelf life, thus gaining a competitive edge in international markets.

The effectiveness of blast freezers in these diverse sectors of the food industry underscores their role in enhancing food preservation and enabling global distribution without sacrificing quality.

Consumer Perception: Does Blast Freezing Affect Taste and Texture?

When considering the impact of blast freezing on the sensory qualities of food, consumer perception plays a critical role in the acceptance and success of this preservation method. Blast freezing rapidly brings food temperatures to below -18°C, a process that is widely believed to help in maintaining the taste and texture of food products close to their fresh state.

Initially, one of the primary concerns is whether blast freezing alters the taste of food. Most consumers report no noticeable change in flavour compared to traditionally frozen goods, and some even prefer the taste of blast-frozen products. The quick-freezing action is designed to avoid the large ice crystal formation that can occur in conventional freezing methods. These large ice crystals are responsible for cellular damage within the food, which can result in a loss of natural flavors and a decline in taste quality.

In terms of texture, blast freezing has an edge over slow freezing. The smaller ice crystals that form during blast freezing cause less disruption to the cell structure of food. This means that upon thawing, the food retains more of its original texture and is less likely to become mushy or lose its firmness.

- Key perceptions include:

- Freshness: Blast frozen foods are often perceived as being fresher than their conventionally frozen counterparts.

- Texture preservation: Consumers generally find the texture of blast-frozen food to be superior, with better retention of firmness.

- Color and visual appeal: There is a consensus that blast-frozen foods maintain their vibrant colors, contributing to a more appetizing appearance.

Fruits, vegetables, and meats are particularly responsive to blast freezing, with many consumers noting that these products maintain a quality that is remarkably close to fresh. However, it’s important to recognise that some delicate foods, like certain seafood or soft fruits, may not fare as well, potentially affecting consumer perceptions of taste and texture negatively in these specific cases.

Sustainability and Energy Consumption in Blast Freezer Operations

Blast-freezing operations have become integral in extending the shelf life of food products. However, these systems are not without their environmental impacts, primarily due to high energy consumption. To maintain sub-zero temperatures, blast freezers use considerable amounts of electricity, which may contribute to the carbon footprint of food preservation if the energy is sourced from non-renewable power plants.

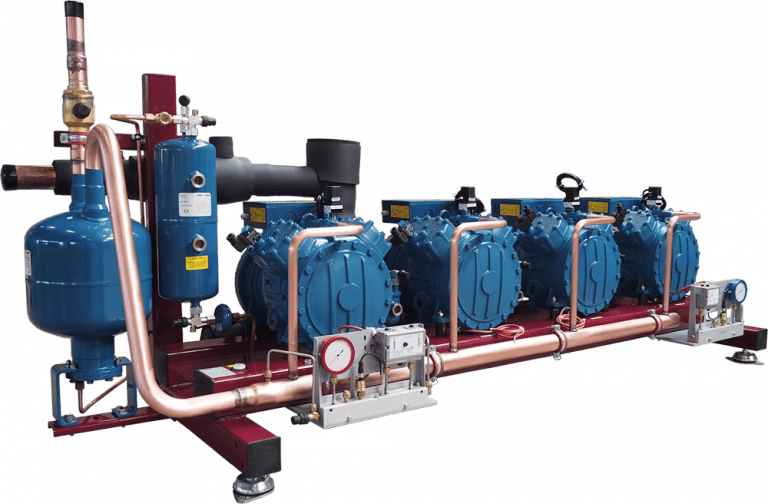

The efficiency of blast freezers can vary significantly. Advanced models incorporate technology such as variable speed drives, high-efficiency compressors, and improved insulation materials to reduce overall energy usage. Some are designed to recover the heat generated by the freezing process, repurposing it to pre-cool products before freezing or for heating other parts of the facility.

Sustainability in blast freezing also encompasses refrigerants used in the cooling process. Traditional refrigerants that have high global warming potential (GWP) are increasingly being replaced with eco-friendly alternatives. These alternatives may have lower GWP, aiding in the reduction of greenhouse gas emissions.

To further sustainability goals, operators of blast freezers can take additional measures:

- Implementing an energy management system to monitor and adjust energy consumption in real time.

- Scheduling operations during off-peak hours to take advantage of lower energy rates and reduced strain on the grid.

- Regularly servicing equipment to maintain optimal performance and efficiency.

- Utilizing renewable energy sources, such as solar or wind power, to supply some or all of the energy needed for freezing operations.

The push towards sustainability in blast freezing is not merely an environmental imperative but also a financial one, as energy-efficient systems can significantly cut down operational costs, making them a smart investment for the future of both the industry and the planet.

The Economics of Blast Freezer: Cost vs. Benefit Analysis

When conducting a cost versus benefit analysis of blast freezing technology, it’s important to balance the significant upfront investment against the potential long-term gains in product quality and shelf-life extension.

Costs

- Initial Investment: Setting up a blast freezer system requires considerable capital for the equipment, installation, and necessary infrastructure modifications.

- Energy Consumption: Blast freezers operate at extremely low temperatures and require considerable amounts of energy, which can lead to high operational costs.

- Maintenance: The complexity of these systems necessitates regular maintenance to ensure efficiency and prevent breakdowns, adding to the ongoing costs.

- Training: Employees must be trained to operate the freezers safely and efficiently, which can be an additional cost for the business.

Benefits

- Shelf-Life Extension: Blast freezing helps in significantly extend the shelf life of products, reducing food waste and the frequency of restocking.

- Quality Preservation: It ensures that the quality, texture, and nutritional value of the food are retained, contributing to higher customer satisfaction and potential premium pricing.

- Streamlining Operations: By allowing for bulk freezing and better inventory management, blast freezers can streamline kitchen operations and improve overall efficiency.

- Market Expansion: The longer shelf life afforded by blast freezing opens up new market opportunities, including exporting to distant markets.

The trade-off between the high initial and operational costs against the extended shelf life and quality preservation often skews in favour of the benefits for businesses operating at scale or in specialized markets where quality is paramount. Furthermore, energy-efficient models and government incentives can mitigate some of the financial burdens. It is essential for businesses to perform a detailed analysis tailored to their specific operation to determine if the investment in blast freezer technology aligns with their strategic goals and financial capabilities.

Innovations and Future Trends in Blast Freezer Technology

As consumer demand for fresh, quality food products grows, the blast freezer industry is continually looking to innovate, making these systems more efficient, sustainable, and integrated with modern technology. Here are several key trends steering the development of future blast freezer technology:

- Energy Efficiency: Manufacturers are developing blast freezers with better insulation and more efficient refrigeration systems to reduce energy consumption. Advances such as CO2 refrigeration systems not only offer greater efficiency but also minimize environmental impact.

- Smart Operation: The incorporation of smart technology allows for more precise temperature control and monitoring. IoT-enabled blast freezers can provide real-time data analytics, predictive maintenance, remote control capabilities, and integration with warehouse management systems.

- Customization and Modular Design: Future blast freezers are trending towards modular designs that can be customized to specific needs—be that size, capacity, or the type of food to be preserved. This enables businesses to scale operations flexibly.

- Processing Speed: Cutting down on blast freezing times while maintaining quality is a key innovation goal. Technologies like cryogenic freezing, using liquid nitrogen, are becoming more accessible and offering faster cooling rates.

- Hygienic Advances: With stricter food safety regulations, the next generation of blast freezers is expected to feature materials and designs that are easier to clean and prevent contamination, such as antimicrobial surfaces.

- Sustainability: There’s a push towards using alternative, eco-friendly refrigerants and reduction of greenhouse gas emissions. Advancements in heat recovery systems also allow waste heat from blast freezers to be reused, conserving energy.

By embracing these innovations, the blast freezer industry not only enhances the quality of food preservation for consumers but also aligns itself with the global need for more environmentally conscientious industrial practices.

Final Thoughts: The Overall Impact of Blast Freezing on the Food Industry

The implementation of blast-freezing technology has ushered in an era of remarkable advancements within the food industry. The transformative power of this method is observed in its ability to exponentially extend the shelf life of perishable goods. By rapidly lowering the temperature of food products, blast freezing minimizes the formation of large ice crystals, thus preserving the cellular structure and nutritional quality of the food. This has had far-reaching implications for both food safety and sensory quality, ensuring that consumers enjoy products that are as close to their fresh state as possible.

Moreover, blast freezers have introduced unparalleled efficiency in logistical operations. Producers and retailers can store food for longer periods without compromising on quality, enabling a more consistent supply and reduced food wastage. This efficiency plays a critical role in the global effort to achieve sustainability targets by mitigating the environmental impact of food production and distribution.

Additionally, blast-freezing technologies have expanded market opportunities for food producers. The ability to export high-quality frozen products over great distances without quality degradation has opened up international markets, fostering economic growth and diversification within the industry. Consequently, culinary options for consumers have become more varied, as exotic and seasonal items are made available year-round.

In conclusion, blast freezing has established itself as a cornerstone of modern food preservation. The collective benefits of improved food safety, enhanced quality, logistical efficiency, and expanded market access underline the significant and positive impact this technology has had on the food industry, securing its role as an essential component of contemporary food systems.