In today’s dynamic global market, industries relying on perishable goods, pharmaceuticals, and temperature-sensitive products recognize the indispensable role of industrial cold storage equipment. These specialized facilities provide a controlled environment to safeguard product quality, extend shelf life, and ensure regulatory compliance. In this article, we delve into the key components of industrial cold storage equipment that contribute to efficient and reliable temperature-controlled solutions.

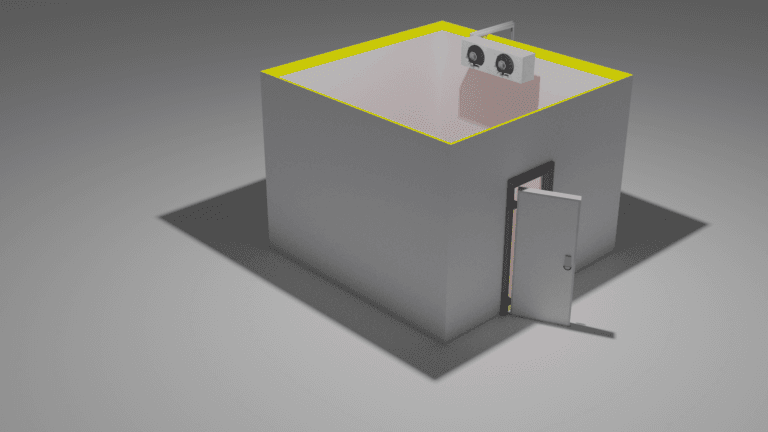

Cold Storage Equipment

1. Insulation Cold Storage Panels:

The foundation of any industrial cold storage space lies in its insulation panels. Crafted from high-quality materials with exceptional insulation properties, these panels form the walls, ceiling, and floor of the storage area. They serve as a barrier against heat exchange, safeguarding products from external temperature fluctuations.

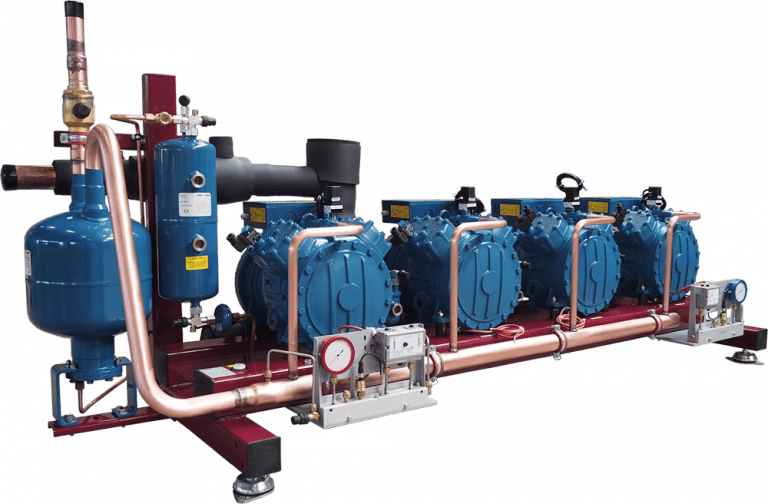

2. Refrigeration System : At the heart of industrial cold storage facilities, the refrigeration system plays a pivotal role. Comprising components such as compressors, condensers, evaporators, and expansion valves, this system facilitates the circulation of refrigerant. By absorbing heat from within the storage area and releasing it outside, the refrigeration system maintains the desired temperature range.

3. Cold Room Doors: Precision-engineered cold storage doors are designed for an airtight seal to prevent temperature leakage. These doors often incorporate features like heated gaskets to prevent ice buildup and ensure consistent sealing integrity.

4. Advanced Temperature and Humidity Control: State-of-the-art temperature and humidity sensors, thermostats, and controllers work in tandem to monitor and fine-tune the storage conditions. These components ensure that the optimal temperature and humidity levels are consistently maintained, safeguarding product quality.

5. Efficient Air Circulation: Unwavering temperature consistency is achieved through effective air circulation systems. Fans and air distribution mechanisms evenly distribute cold air, eliminating temperature stratification and ensuring uniform product conditions.

6. Intelligent Shelving and Racking: Industrial cold storage spaces are equipped with smart shelving and racking solutions that optimize storage capacity. These systems are designed to maximize space while allowing easy access to stored items.

7. Robust Flooring: Durable flooring materials that withstand low temperatures and provide a non-slip surface are essential. These materials ensure safety for personnel while also preventing damage to stored products.

8. Adaptive Lighting Solutions: To minimize heat generation while maintaining visibility, LED lighting solutions are commonly integrated into industrial cold storage spaces. These lights illuminate the area without compromising the temperature control environment.

9. Comprehensive Monitoring and Alert Systems: Advanced monitoring systems continuously track temperature, humidity, and other critical parameters. Instant alerts are triggered if conditions deviate from the preset range, allowing swift corrective actions to be taken.

10. Power Backup and Security Measures: Industrial cold storage facilities often incorporate backup power systems to ensure uninterrupted operation during power disruptions. Security measures, including access control and surveillance systems, safeguard both the stored products and the facility itself.

11. Remote Accessibility and Data Logging: Modern technology enables remote access and data logging capabilities. Operators can monitor and manage storage conditions remotely, while data logs provide valuable insights for quality assurance and compliance purposes.

12. Defrosting Mechanisms: To maintain optimal efficiency, automated defrosting systems prevent the buildup of ice on evaporator coils, ensuring consistent temperature regulation.

13. Ventilation Solutions: Adequate ventilation prevents condensation and promotes air quality within the cold storage environment.

In conclusion, industrial cold storage equipment forms a sophisticated ecosystem that ensures the integrity and quality of temperature-sensitive products. From precision control systems to advanced monitoring solutions, each component plays a vital role in creating an environment that meets regulatory requirements, extends product shelf life, and enhances overall operational efficiency. As industries continue to evolve, the role of industrial cold storage equipment remains central to maintaining product excellence in a competitive market.