The purpose of providing cold storage humidity control is to provide a constant relative humidity as much as possible. The equilibrium state of relative humidity in the cold storage; The characteristics of the product and package to be put into the warehouse, the way it is stacked in the cold storage, the surface areas and structures of the evaporators, the placement of the evaporators, the difference between the evaporator surface temperature and the room temperature, the insulation of the cold storage, the air distribution environment in the cold storage, the air exchange coefficient and the cold room. varies depending on the operating time of the devices. In order to provide the desired relative humidity in the cold storage, it is necessary to wait for a certain period of time and take some precautions.

Factors Affecting Cold Storage Humidity Control

Characteristics of the Product and Packaging

Changes in the transpiration density of the product in the cold room have a greater effect, especially when the product is started to be cooled. The dryness of the packages made of materials (wood, cardboard, etc.) that absorb or reabsorb water very quickly is an important factor. If the packages are too wet, the opposite effect will occur.

Filling the Cold Storage Warehouse Effect To Cold Storage Humidity Control

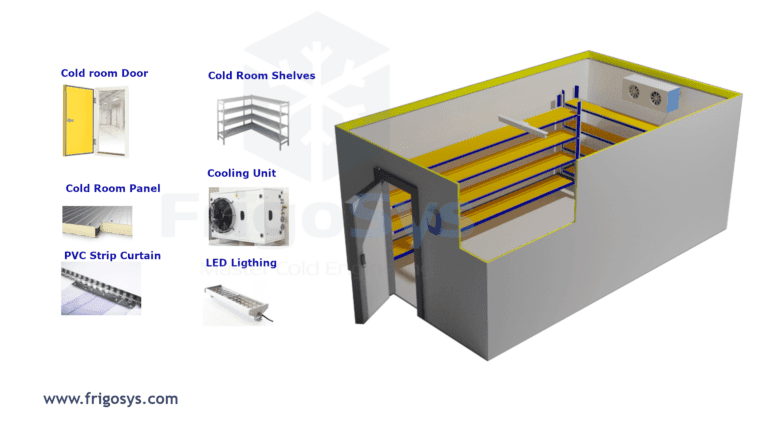

The filling situation of the cold storage varies considerably, especially at the beginning and end of the warehouses. The way of placing the product to be stored in cold rooms should be done in accordance with the free circulation of air. In this way, it is ensured that the cold room air mixes sufficiently and easily, and the humidity remains within the appropriate limits.

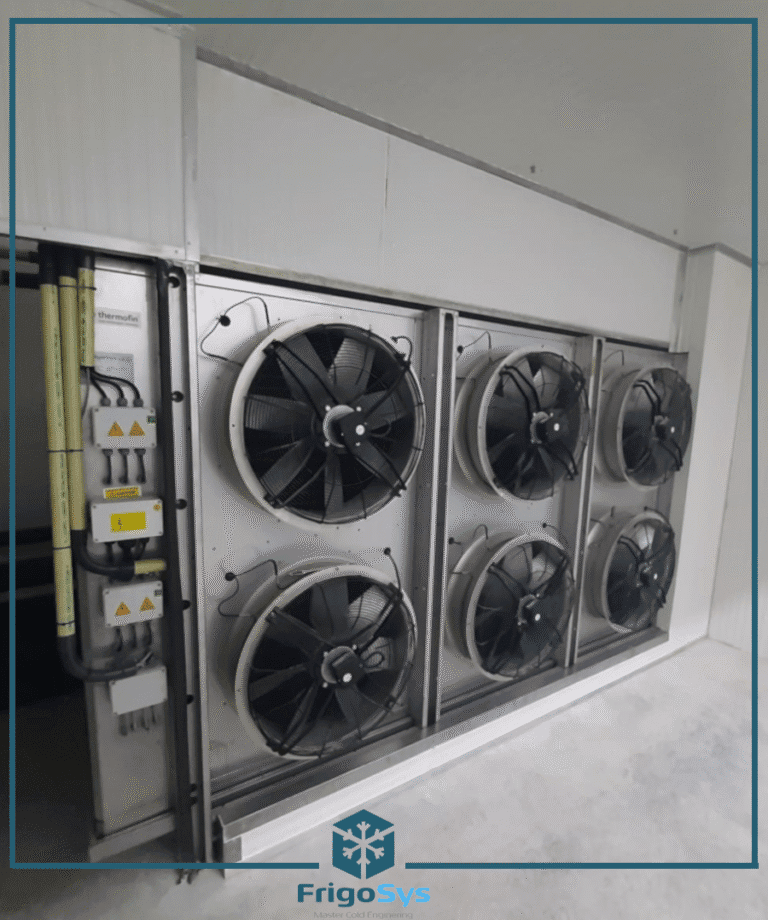

Surface Areas of Evaporators, Structures and Placement of Fans

The surface areas of the evaporators, the number of fans, the cross-sectional area, and the airflow rates directly affect the humidity of the cold storage. For example, in order to obtain high relative humidity (80-90%) in the cold store, evaporators with large coil areas should be available.

Difference Between Evaporator Surface Temperature and Room Temperature

Considering the losses due to the calculated heat permeability, care should be taken to keep the temperature difference between the refrigerant and the cold room as low as possible. In practice, a difference of 5 °C can be accepted between the average temperature of the cold room and the temperature of the refrigerant. If the temperature difference between the cold room average temperature and the refrigerant temperature is more than 5 °C, condensation begins to form in the water vapor in the air; This situation causes the formation of frost on the cold room evaporator. As the relative humidity in the cold room decreases, the air in the cold room begins to absorb moisture from the stored product, thus causing the product to fade and lose its freshness.

Insulation of Cold Storage Affecting Cold Storage Humidity Control

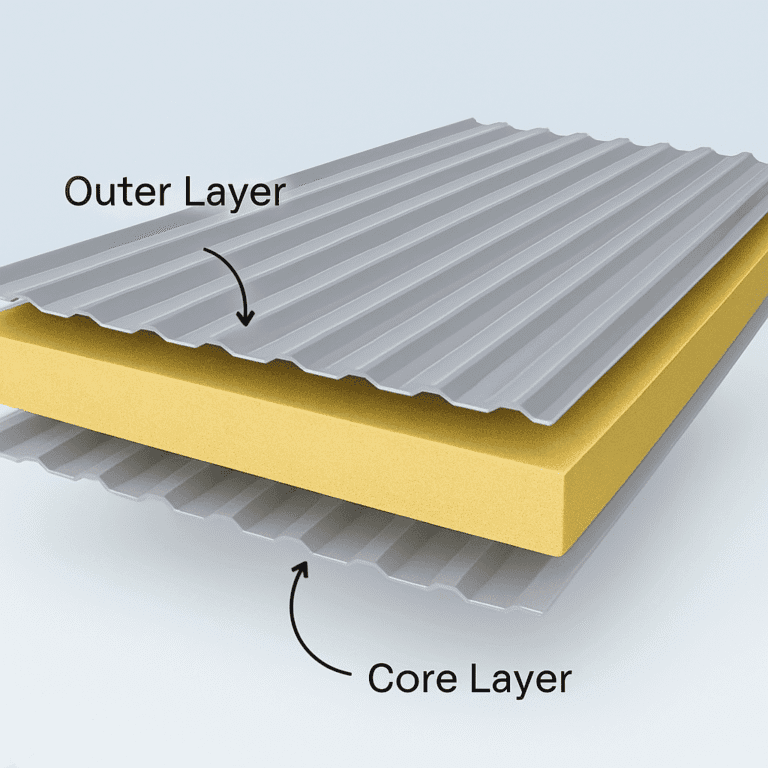

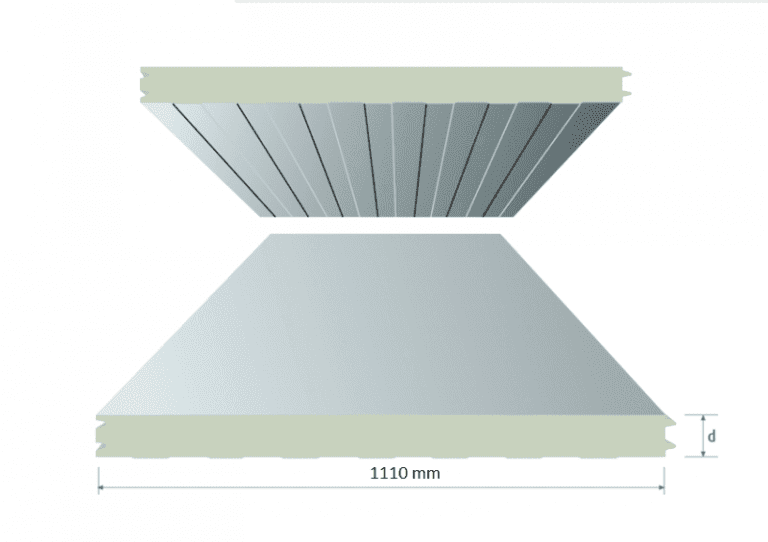

The type of insulation material and its economic thickness value are extremely important in cold storage. The insulation material, which is of such importance, must be protected against moisture transfer and thus wetting.

The outside temperature is usually higher than the temperature of the cold room air is high. The humidity pressure of higher temperature air will also be higher than the humidity pressure of cold room air at lower temperatures. The humidity that will condense within the insulation material during this movement will cause the insulation material to get wet and thus the insulation property will be lost.

In order to prevent this situation, that is, to protect the insulation material against moisture transfer, a moisture barrier should be applied to the surface of the insulation material towards the outside air, according to the wall-filling structure. As a moisture barrier, asphalt-characterized paints and bitumen, ruboraite, PVC sheets, canvas or glass tulle pulps and aluminum foil etc. can be used. Materials with high moisture resistance are used. In polyurethane sandwich panel applications, heat and moisture insulation are solved together.

Air Distribution Environment, Distribution Rate and Coefficient of Change in Cold Storage

Air movement/circulation in cold stores should be such that an equal temperature and humidity level should be maintained in all volumes. Excessive air movement can cause water loss in foodstuffs. This is both unnecessary and harmful. On the other hand, good air distribution is useful and necessary. If the stacking is bad and prevents air distribution, ducted air distribution should be preferred in cold storage.

Cold Storage Humidity Values of Various Substances

Vegetables 90-100% RH

Dry Foods 60-70% RH

Various Seeds 55-65% RH

Sea-Foods 90-100% RH

Shellfish 95-100% RH

Meat (Beef) 85-92% RH

Meat (Mutton) 85-95% RH

Meat (Poultry) 85-95% RH

Daily Productions 60-85% RH

Confectionery 40-65% RH

Source: MMO