Cold storage is a vital preservation method that helps to maintain the quality, freshness, and shelf life of perishable fruits and vegetables. By controlling the temperature and humidity within specialized facilities, it slows down the biochemical processes that lead to decay. This is crucial both for keeping produce in prime condition from farm to market and for reducing food waste. Moreover, cold storage can help stabilize market prices by allowing a year-round supply of seasonal produce. Thus, it plays an essential role in the global food supply chain.

Understanding the Science of Cold Storage: Temperature, Humidity, and Airflow

Cold storage science is critical for fruit and vegetable preservation. Three primary environmental factors must be carefully controlled:

- Temperature: Most perishable goods require storage at low temperatures to slow down biological processes and microbial growth. Each type of produce has an optimal temperature range.

- Humidity: Maintaining the correct humidity level is essential to prevent dehydration and wilting. Too much humidity, however, might encourage fungal growth.

- Airflow: Proper airflow ensures an even distribution of cool air and helps prevent the buildup of ethylene gas, which can hasten ripening and spoilage.

These controlled conditions work together to extend the shelf life of fruits and vegetables by manipulating their metabolic and respiratory rates.

Categories of Fruits and Vegetables: Responsiveness to Cold Storage

Different fruits and vegetables have varying responses to cold storage based on their physiological properties. Broadly, they can be categorized into climacteric and non-climacteric groups:

- Climacteric Fruits and Vegetables: These produce ethylene and continue to ripen after harvest. Cold storage can slow down the ripening process. Examples include apples, bananas, and tomatoes.

- Non-Climacteric Fruits and Vegetables: These do not produce significant amounts of ethylene and do not ripen post-harvest. Cold storage mainly preserves their freshness. Examples are grapes, citrus fruits, and cucumbers.

Specific temperature and humidity control are crucial for maximizing shelf life and maintaining quality across both categories.

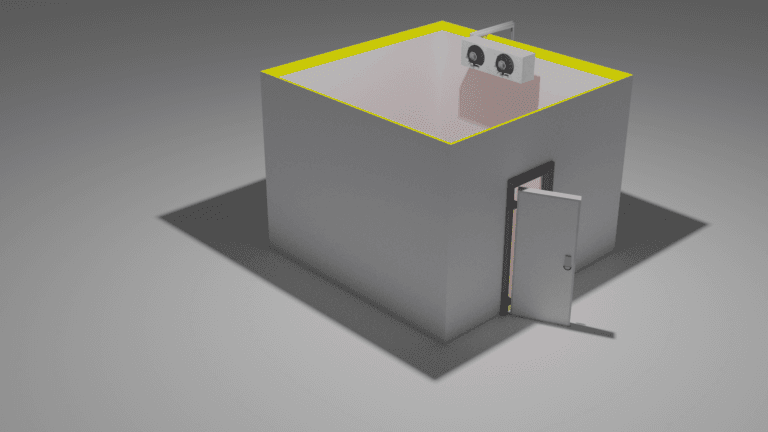

Cold Storage Facilities: From Home Fridges to Commercial Warehouses

Cold storage facilities are essential for preserving the freshness and extending the shelf life of fruits and vegetables. At the domestic level, home refrigerators operate at temperatures around 35-38°F, appropriate for many household produce items. These units entail individual compartments, controlling humidity and temperature to maintain quality.

At a commercial scale, large cold storage warehouses are utilized. These facilities offer:

- Controlled environments for different produce requirements

- Refrigerated loading docks to minimize exposure to external temperatures

- Advanced refrigeration systems ensure uniform temperature distribution

- Monitoring systems for real-time temperature and humidity tracking

Building a bridge between the farm and the consumer, these cold storage solutions are crucial in the supply chain for ensuring produce arrives in prime condition.

The Impact of Proper Packaging on Cold Storage Effectiveness

Proper packaging plays a critical role in maintaining the quality and longevity of fruits and vegetables during cold storage. Here are some reasons how effective packaging impacts cold storage:

- It protects produce from mechanical damage and bruising during handling and transportation.

- Packaging acts as a barrier against moisture loss, keeping the produce hydrated and fresh.

- It helps in maintaining an optimal microclimate around the produce, which can slow down respiration and degradation.

- Proper packaging materials can prevent the entry of pests that can spoil the stored items.

- Using the correct packaging can reduce the risk of cross-contamination between different types of produce.

- Specialized packaging can include modified atmosphere conditions, further enhancing the storage life of fruits and vegetables.

By investing in the right packaging solutions, cold storage effectiveness is significantly improved, leading to fresher produce for the end consumer.

Temperature Control: Optimal Settings for Various Types of Produce

Effective cold storage requires understanding the unique temperature needs of each type of produce. Here are some optimal settings for different categories:

- Leafy Greens: 32–36°F (0–2°C), high humidity to prevent wilting

- Root Vegetables: 32–40°F (0–4°C), moderate humidity to avoid dehydration

- Citrus Fruits: 38–48°F (3–9°C), relatively low humidity to prevent mold

- Tropical Fruits: 50–60°F (10–15°C), moderate humidity to maintain freshness

- Stone Fruits: 31–32°F (-0.5–0°C), high humidity to prevent shriveling

- Tomatoes: 55–65°F (13–18°C), low humidity to keep skins firm

Different varieties within each group may require slight adjustments, but these ranges maximize shelf life and quality.

Managing Humidity Levels to Prevent Spoilage and Wilting

Humidity control is crucial in the cold storage of fruits and vegetables. Too much humidity can lead to condensation and mold growth, while too low humidity may cause dehydration and wilting. Managing humidity levels varies with the type of produce.

- Leafy Vegetables: High humidity (around 95%) is required to stay fresh.

- Root Vegetables: Best stored at moderate humidity levels to prevent sprouting or rot.

- Fruit: Generally requires lower humidity than vegetables to prevent fungal growth.

Use humidifiers or dehumidifiers accordingly, and ensure the storage space is well-ventilated to maintain consistent humidity. Regularly check the produce for spoilage signs and adjust humidity settings as needed to extend shelf life and maintain quality.

Cold Chain Logistics: Maintaining Freshness from Farm to Table

Cold chain logistics is crucial for preserving the quality and safety of fresh produce from the moment it leaves the farm until it reaches the consumer’s table. It involves:

- Strict Temperature Control: To prevent spoilage and ensure the produce remains fresh, an unbroken cold storage chain is maintained.

- Efficient Transportation: Refrigerated trucks, shipping containers, and air cargo transport fruits and vegetables quickly and safely.

- Real-Time Monitoring: Sensors and tracking technology allow for constant monitoring of temperature and humidity levels during transit.

- Compliance with Regulations: Adherence to food safety standards and regulations is essential to prevent contamination and ensure public health.

- Expert Handling: Trained professionals manage the loading, unloading, and storage to minimize damage to delicate produce.

By meticulously managing each step of cold chain logistics, freshness from farm to table is ensured, giving consumers high-quality, fresh produce.

Troubleshooting Common Cold Storage Issues: Freezer Burn and Ethylene Production

When preserving fruits and vegetables in cold storage, two prevalent issues are freezer burn and ethylene production. To tackle these challenges:

- Freezer Burn: This condition occurs when air reaches the food’s surface, leading to dehydration and oxidation. To prevent freezer burn:

- Ensure proper packaging by using airtight containers or vacuum-sealed bags.

- Minimize the storage time.

- Keep the freezer temperature consistent and avoid frequent openings.

- Ethylene Production: Ethylene is a gas that can hasten ripening and spoilage. To control ethylene:

- Store ethylene-producing items (like apples and bananas) separately from sensitive produce (like leafy greens).

- Use ethylene absorbers or filters in storage areas.

- Maintain proper ventilation to dissipate ethylene gas.

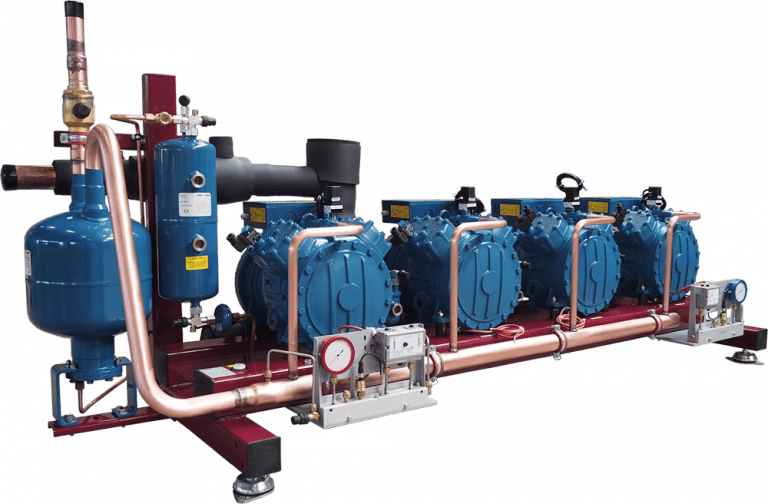

Technology in Cold Storage: Advances and Innovations

Recent advancements in cold storage technology have revolutionized the preservation of fruits and vegetables. The advent of Cryogenic freezing employs liquid nitrogen for rapid cooling, significantly reducing the risk of cellular damage. Advanced Compressor technology is now more energy-efficient, providing better temperature control while reducing operational costs. Real-time monitoring systems ensure consistent environmental conditions, with IoT devices enabling remote control and data analysis. Robotics and automation have streamlined storage management, allowing for more precise handling and reduced labor costs. Additionally, Eco-friendly refrigerants are becoming commonplace, helping reduce the carbon footprint of cold storage facilities. These innovations lead to extended shelf life and enhanced quality of stored produce.

Hygiene and Safety Practices in Cold Storage Environments

Maintaining hygiene and safety in cold storage units is crucial for preserving the quality of fruits and vegetables. Workers should adhere to rigorous standards:

- Personal hygiene protocols, including regular handwashing and clean uniforms, prevent contamination.

- Cold storage areas must be regularly cleaned and sanitized to inhibit bacterial growth and cross-contamination.

- Safety gear such as insulated gloves, non-slip footwear, and appropriate cold-weather attire is mandatory to protect staff from cold-related injuries.

- Proper training on equipment handling reduces the risk of accidents and ensures efficient operation.

- Monitoring for gas leaks, particularly ammonia from refrigeration systems, ensures the health and safety of personnel.

- Implementing a HACCP (Hazard Analysis and Critical Control Points) plan helps manage potential biological, chemical, or physical hazards.

These measures safeguard the integrity of produce and ensure a secure working environment.

Cold Storage Tips for Consumers: Making Produce Last Longer at Home

- Use the Crisper Drawer: Store fruits and vegetables in the fridge’s crisper drawer to maintain freshness and humidity levels.

- Separate Ethylene Producers: Keep ethylene-producing fruits like apples and bananas away from other produce to prevent premature ripening.

- Wrapping Greens: Wrap leafy greens in a dry paper towel and place them in a breathable bag before refrigerating to extend their life.

- Proper Ventilation: Ensure your fruits and vegetables have good air circulation and are not packed too tightly in the fridge.

- Temperature Settings: Maintain your refrigerator’s temperature between 35-40°F (1.6-4.4°C) for optimal storage conditions.

- Freezing: Freeze surplus fruits and vegetables at peak ripeness to preserve their quality, especially if you can’t consume them promptly.

- Avoid Washing: Don’t wash produce before refrigerating as the moisture can promote mold growth; wash just before eating.

- Regular Checks: Regularly check for spoiled items and remove them to prevent the spread of decay to other produce.

Conclusion: The Future of Cold Storage and Sustainable Practices

The future of fruit and vegetable cold storage is set to be deeply intertwined with sustainable practices. As the global focus on environmental preservation intensifies, innovations in cold storage technology are increasingly leaning towards energy efficiency, reduced carbon footprints, and the integration of renewable energy sources. Industry leaders must focus on:

- Harnessing advanced insulative materials to minimize thermal exchange.

- They are implementing smart systems for real-time monitoring to optimize energy use.

- Exploring alternative, eco-friendly refrigerants to lower global warming potential.

- Collaborating across supply chains to reduce waste and improve logistics.

Future cold storage solutions will likely be defined by their ability to balance operational efficiency with environmental stewardship, ensuring food safety and quality without compromising the planet’s health.