Milk and dairy products play a crucial role in our daily diets, providing essential nutrients and flavors. However, maintaining their freshness and quality requires efficient cooling systems throughout the production and storage process. In this article, we’ll explore the importance of cooling systems for milk and dairy products and keep optimal cooling principles in mind.

The Significance of Cooling Systems for Milk and Dairy Products

Effective cooling systems are paramount in the dairy industry to prevent spoilage, bacterial growth, and quality degradation. Proper cooling inhibits the proliferation of harmful microorganisms, preserves nutritional value, and extends shelf life. With consumer demand for safe and high-quality dairy products on the rise, dairy producers must invest in advanced cooling solutions to meet these expectations.

Bulk Milk Cooling Tanks

Bulk milk cooling tanks are at the heart of dairy operations. These sizable stainless steel tanks rapidly cool large quantities of raw milk immediately after milking. This quick cooling, typically to around 4°C (39°F), inhibits bacteria and preserves the milk’s natural freshness. Using refrigeration units and agitators, these tanks maintain even temperatures and prevent the separation of cream layers, ensuring uniform quality.

Plate Heat Exchangers

Plate heat exchangers are innovative devices that enhance cooling efficiency. By transferring heat between two fluids without direct contact, they pre-cool milk before it enters bulk milk tanks. This process minimizes the load on the primary cooling system and optimizes energy usage. Utilizing plate heat exchangers can significantly improve cooling processes and resource utilization.

Instantaneous Cooling Systems

Instantaneous cooling systems employ heat exchangers to rapidly cool milk using chilled water or refrigerants. These systems offer efficiency in smaller dairy operations, ensuring swift cooling while maintaining product integrity. The streamlined design of these systems contributes to cost savings and resource conservation.

Cold Water Refrigeration ( Chiller )

Cold water refrigeration employs chilled water circulation through cooling coils or jackets surrounding milk storage tanks. This technique maintains consistent temperatures within tanks, preventing temperature fluctuations that could compromise product quality. Cold water refrigeration systems are suitable for smaller-scale dairy facilities.

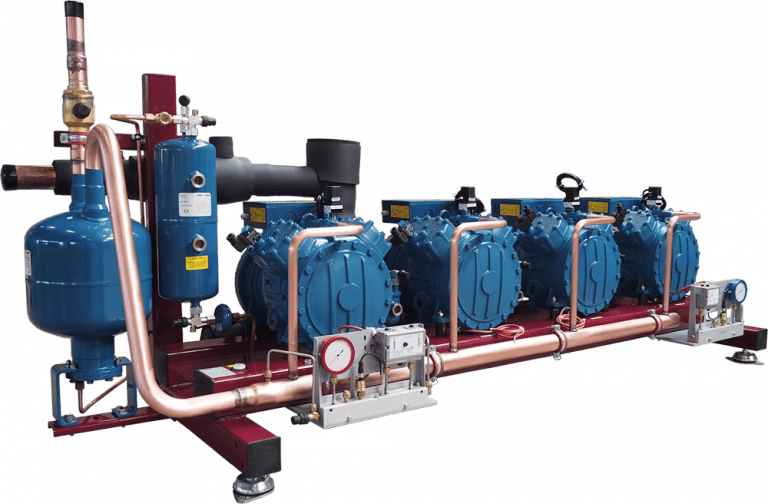

Direct Expansion Refrigeration

Direct expansion refrigeration systems use refrigerants to directly cool milk within cooling coils or plates. Renowned for precise temperature control and suitability for more extensive dairy operations, these systems ensure optimal cooling conditions for product quality and safety.

Cooling Tunnels for Dairy Products

Dairy products such as yogurt, cheese, and butter require careful cooling after processing. Cooling tunnels gradually lower product temperatures using chilled air or cold water, safeguarding product consistency and integrity. Controlled cooling in these tunnels contributes to product excellence and extends shelf life.

Conclusion

Efficient cooling systems are the backbone of the dairy industry, preserving the quality, safety, and freshness of milk and dairy products. With various cooling methods available, producers can tailor their approaches to the scale of their operations and the types of products they offer. By investing in advanced cooling solutions, dairy producers can ensure consumer satisfaction, comply with industry standards, and contribute to the production of top-tier dairy products.