Understanding the Basics of Cold Rooms

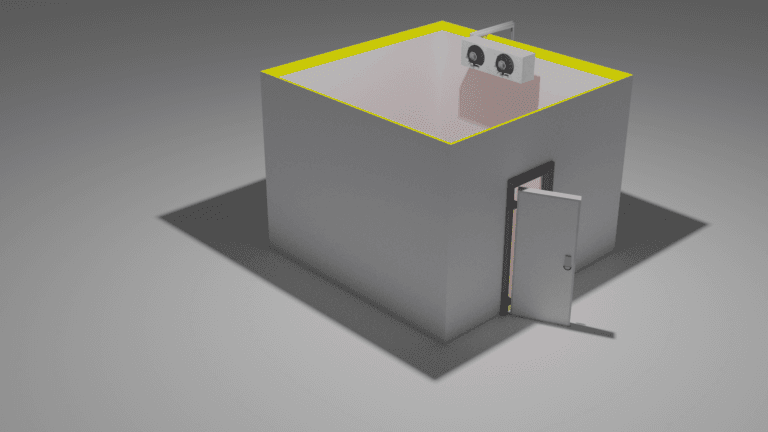

Cold rooms are specialized storage spaces designed to maintain low temperatures, ensuring the preservation of perishable goods. They are essential in industries such as food processing, pharmaceuticals, and logistics. Cold rooms typically rely on refrigeration systems to regulate the internal climate, keeping items fresh and protected from spoilage.

Key components of a cold room include:

- Cold Room panels: Prevent heat transfer and maintain temperature consistency.

- Refrigeration units: Provide cooling to meet specific temperature requirements.

- Temperature controls: Allow precise adjustments for different storage needs.

Cold rooms come in various sizes, from small modular units to large walk-in chambers, enabling flexibility for diverse applications. The size affects the cold room prices.

Why are cold room prices important for your business?

Affordable cold rooms play a vital role in ensuring businesses have reliable and cost-effective storage for temperature-sensitive products. Cold rooms are essential for industries such as food service, pharmaceuticals, and agriculture, where maintaining product quality and safety depends on strict temperature control. Accessible pricing allows small and medium-sized enterprises (SMEs) to compete with larger organizations by reducing overhead costs.

Cost-efficient cold rooms minimize waste by preserving perishables for longer periods. Additionally, choosing an affordable option ensures businesses can allocate resources to other critical areas, such as product innovation or operational growth. Reduced energy costs in well-designed cold rooms further enhance operational efficiency.

Key Factors That Influence Cold Room Prices

Several factors contribute to the cost of a cold room, making it essential to evaluate each component carefully. These key factors include:

- Size and Capacity: Larger cold rooms with higher storage capacities tend to cost more due to increased material and labor requirements.

- Temperature Range: Cold rooms designed for ultra-low temperatures typically require advanced insulation and specialized cooling systems, driving up the price.

- Insulation Materials: High-quality insulation, such as polyurethane or polystyrene, enhances temperature retention but adds to the overall cost.

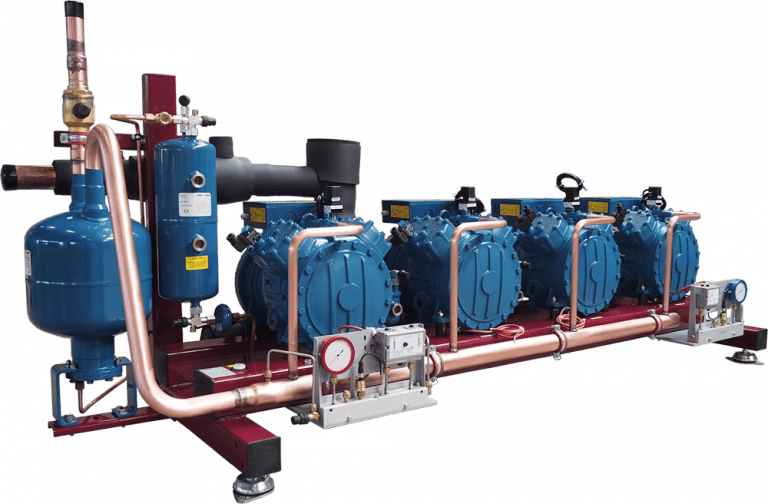

- Cooling Systems: The type and efficiency of the refrigeration unit significantly impact pricing, with energy-efficient models often being pricier initially.

- Customization Needs: Additional features like shelving, doors, alarms, or monitoring systems increase customization costs.

- Location and Installation: Transport and installation expenses vary based on geographical location and site-specific requirements.

These variables collectively shape cold room pricing structures.

How to Research and Compare Cold Room Prices Effectively

It is essential to adopt a systematic approach to identify the most suitable cold room supplier. Start by compiling a list of reputable suppliers through online research, industry referrals, and reviews. Evaluate their credibility by examining certifications, product warranties, and customer feedback. Analyze their product range to ensure compatibility with specific requirements, such as size, temperature range, and energy efficiency.

Next, request detailed quotations, including installation and maintenance costs, ensuring clarity on hidden fees. Compare these quotes alongside delivery timelines and after-sales support. Lastly, visit client references or inspect existing installations to confirm quality and reliability before making a decision.

Spotting Low-Cost Options Without Compromising on Quality

Finding affordable cold rooms that maintain high quality requires careful evaluation and comparison. Buyers should first identify reputable manufacturers or suppliers known for durable and efficient systems. Key factors to assess include: insulation thickness, energy efficiency ratings, and material durability. Opting for standard sizes rather than custom builds can significantly reduce costs.

- Ask for warranties to ensure long-term performance.

- Compare models to weigh features against price.

- Consider refurbished options inspected by professionals for safety and reliability.

Requesting multiple quotes also ensures competitive pricing. Seeking advice from industry professionals or reviews can highlight cost-efficient options without sacrificing performance. Emphasis should always remain on quality over price.

Leveraging Online Platforms to Find the Best Deals

Online platforms provide an extensive range of options for comparing cold room prices, enabling businesses to identify affordable solutions efficiently. E-commerce websites, such as industry-specific marketplaces, often list products with detailed specifications and pricing. Buyers can compare these features across multiple sellers to assess value for money.

Utilizing review platforms allows users to evaluate the reputation of manufacturers and suppliers by considering feedback from previous buyers. Subscription to newsletters or alerts from relevant websites ensures timely updates on discounts or promotions. Social media groups or forums dedicated to refrigeration solutions often share recommendations or verified deals, offering additional avenues for exploration.

The Importance of Energy Efficiency in Reducing Long-Term Costs

Energy efficiency plays a pivotal role in managing operational costs for cold rooms. Highly insulated panels and energy-efficient compressors can significantly reduce electricity consumption, offering cost savings over time. By utilizing features like variable speed drives and auto-defrost mechanisms, cold rooms can optimize power usage without compromising performance. Additionally, energy-efficient cold rooms tend to have lower heat loss, maintaining stable temperatures with minimal effort.

Investing in energy-efficient systems also reduces wear and tear on components, extending the lifespan of equipment. Businesses may benefit further by taking advantage of government incentives or utility rebates for energy-efficient installations.

Negotiation Tips to Secure Better Cold Room Discounts

- Research Market Pricing: Gather quotes from multiple suppliers to understand the standard market price. This knowledge strengthens the bargaining position.

- Buy in Bulk: Suppliers often offer discounts on bulk purchases. Leverage this to negotiate lower rates if buying multiple units.

- Timing Matters: Engage suppliers during offseason periods or end-of-quarter sales when discounts are more likely.

- Highlight Long-term Value: If planning future purchases, emphasize potential repeat business to secure loyalty discounts.

- Inspect Add-ons: Negotiate for additional features or maintenance services included in the price without extra costs.

- Leverage Competitor Deals: Bring attention to competitor offers to encourage suppliers to match or beat the price.

Evaluating Warranty and After-Sales Support on a Budget

When purchasing a cold room, reviewing warranty and after-sales support is crucial for maximizing value, especially when working with a limited budget. Reliable warranties often indicate manufacturer confidence in their product, offering peace of mind against potential defects. Buyers should compare warranty terms, such as coverage duration, included repairs, and exclusions.

After-sales support plays a key role in minimizing downtime and reducing long-term costs. Check if vendors offer 24/7 support, efficient technician networks, and quick access to replacement parts. Affordable solutions can still provide substantial support if chosen carefully. Prioritizing these factors ensures cost-effectiveness without compromising reliability.

Making the Final Decision: Balancing Affordability and Functionality

When choosing a cold room, it is essential to balance cost-effectiveness and operational efficiency. Focusing solely on price may sacrifice key features while prioritizing advanced specifications could inflate the budget unnecessarily. Decision-makers should consider factors like the intended storage capacity, temperature range, and energy efficiency to ensure the unit effectively meets business needs.

Key priorities include:

- Storage capacity: Sizing the cold room to match storage demands prevents underutilization or overcrowding.

- Temperature control: Look for adjustable systems for specific products like perishable food or pharmaceuticals.

- Energy consumption: Lower energy usage offsets long-term costs without compromising performance.

Analyzing these elements allows for an informed purchase, ensuring functionality within budget constraints.