Industrial refrigeration systems are critical components in a wide range of industries, ensuring products are kept at the necessary temperatures for preservation and safety. The importance of these systems cannot be overstressed, as they are integral to maintaining the integrity of perishable goods throughout various stages of production, storage, and transportation.

- Food and Beverage Industry: Here, refrigeration is essential for preventing spoilage and bacterial growth, especially in dairy, meat, and processed foods. It enables manufacturers to adhere to health and safety standards while extending the shelf life of products.

- Pharmaceutical Industry: Many medications and vaccines require controlled temperature environments. Industrial refrigeration ensures that these sensitive products remain effective and safe for use.

- Chemical Industry: Certain chemicals are volatile or reactive at higher temperatures. Refrigeration systems help in storing these substances safely, preventing unwanted reactions that could be dangerous.

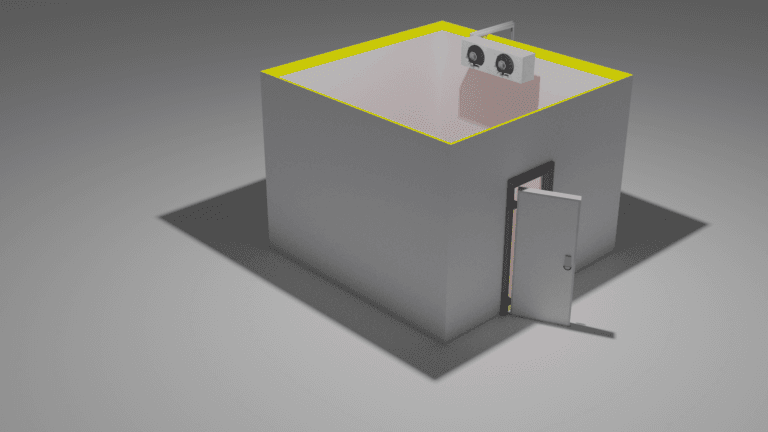

- Cold Storage Warehousing: A vast network of cold storage facilities relies on industrial refrigeration to preserve large quantities of perishable goods before they are distributed to retailers and consumers.

- Agriculture: Farmers use industrial refrigeration for the storage of harvested produce, protecting it from heat and delaying ripening or decay.

- Ice-Cream and Frozen Foods Production: Consistent and reliable cooling is vital for quality and texture in the production of frozen desserts and meals.

Industrial refrigeration is not just about cooling; precise temperature control is often essential for product quality and consistency. The use of these systems spans numerous sectors, with each application having its own specific requirements and challenges. Consequently, maintaining the operational efficiency of these complex systems is essential to avoid disruptions that could lead to financial losses or health risks.

Understanding the Basic Components of Industrial Refrigeration

Industrial refrigeration systems are complex assemblies made up of several crucial components that work together to facilitate the cooling process required in various industries. These systems are generally larger and more powerful than commercial or domestic units because they are designed to function on an industrial scale, meeting the substantial cooling demands of sectors such as food processing, pharmaceuticals, and chemical manufacturing.

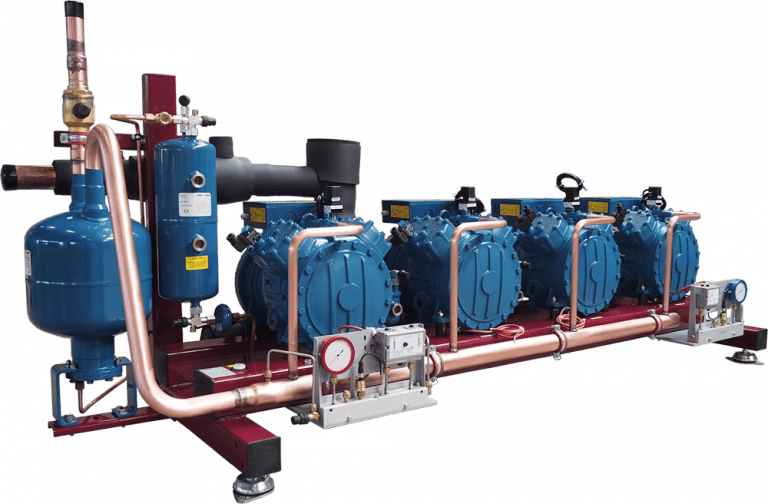

- Compressors: These are the heart of the refrigeration system, responsible for compressing the refrigerant, thereby raising its pressure and temperature. They come in various types, such as screw, reciprocating, or centrifugal, based on the specific needs of the installation.

- Condensers: Serving to remove heat from the compressed refrigerant, condensers can be air-cooled, water-cooled, or evaporative. As the refrigerant releases its heat, it transitions from a gas to a liquid state.

- Evaporators: In this component, the liquid refrigerant absorbs heat from its surroundings and evaporates, thus providing the cooling effect. The design of the evaporator varies according to the application, from plate-type to finned coils.

- Expansion Valves: This device precisely controls the amount of refrigerant that flows into the evaporator, expanding and reducing its pressure, readying it for another cycle of heat absorption.

- Refrigerant: The medium that carries heat through the system, commonly substances like ammonia, carbon dioxide, or hydrofluorocarbons (HFCs). The choice of refrigerant is governed by factors like efficiency, environmental impact, and safety.

- Piping and Valves: These provide pathways for the refrigerant to travel through the system and are equipped with valves to allow for the control and regulation of refrigerant flow.

- Controls and Sensors: Modern industrial refrigeration systems are equipped with sophisticated sensors and controllers for monitoring temperature, pressure, and flow rates. This allows for automation and precise management of the cooling process.

Understanding these components is essential for anyone overseeing the operation and maintenance of an industrial refrigeration system, ensuring efficient and reliable cooling performance.

The Role of Preventive Maintenance in Refrigeration System Longevity

Preventive maintenance is critical in ensuring that industrial refrigeration systems operate efficiently over their entire lifespan. Regularly scheduled maintenance optimises system performance and helps prevent unexpected breakdowns, which can be costly in terms of both repair expenses and downtime.

- Early Detection of Issues: Preventive maintenance allows for the early detection and rectification of potential problems. Spotting issues like refrigerant leaks or compressor wear early on can prevent more significant system failures down the line.

- System Efficiency: Routine checks and maintenance keep the refrigeration system running at peak efficiency. Clean coils, for example, facilitate better heat transfer, while well-lubricated moving parts reduce friction and energy use.

- Prolonged Equipment Lifespan: By keeping all components in good working order, preventive maintenance reduces the strain on the refrigeration system. This conservative approach extends the life of the equipment, eliminating the need for frequent replacements.

- Consistency in Performance: A well-maintained refrigeration system offers consistent performance. Temperature fluctuations can be minimised, ensuring the protection of the perishable goods being stored or processed.

- Safety and Compliance: Regular maintenance also ensures the system adheres to safety standards and regulatory compliance. This is especially important for industries where refrigeration is critical, such as in food processing or pharmaceuticals.

- Cost Savings: In the long run, preventive maintenance is more cost-effective. It mitigates the risk of large-scale repairs and reduces energy consumption, leading to lower operational costs.

Incorporating a preventive maintenance schedule into the routine operation of an industrial refrigeration system is not merely a recommended practice—it is an indispensable aspect of responsible system management. The longevity and reliability of the refrigeration system profoundly depend on such proactive measures.

Daily and Weekly Inspection Checklists for Operators

Operating a robust and efficient industrial refrigeration system requires constant vigilance. To ensure this, there are certain checks that operators should carry out on a daily and weekly basis.

Daily Inspection Checklist

Operators should perform the following checks every day to confirm the proper functioning of the refrigeration system:

- Visual Inspection: Check for any signs of leaks, abnormal noise, or vibration, and inspect the condition of insulation and piping.

- Pressure and Temperature Monitoring: Verify that suction, discharge, and oil pressures, as well as evaporator and condenser temperatures, are within normal operating ranges.

- Control Settings Verification: Check that all system controls, such as thermostats, pressure controls, and safety switches, are set correctly and functioning.

- Oil Levels and Quality Check: Observe oil levels in the compressors and gauge the oil quality to ensure there are no signs of contamination.

Weekly Inspection Checklist

On a weekly basis, operators should dig a little deeper with these checks:

- Condenser and Evaporator Inspection: Look for any scaling, fouling, or blockages that could impair heat transfer efficiency.

- Compressor Analysis: Listen for any irregular sounds that could indicate compressor wear or damage and inspect for any signs of overheating or oil leakage.

- Electrical Connection Assessment: Examine all wiring, connections, and fuses for signs of overheating, corrosion, or damage.

- Refrigerant Level Check: Confirm that refrigerant levels are adequate and search for potential leaks.

- Airflow Verification: Ensure that fan motors, blades, and coils are free from obstruction and debris to maintain optimal airflow.

- Defrost Function Test: If applicable, test the defrost cycle to make sure it’s operating as intended.

- Record Keeping: Update maintenance logs with findings and actions taken. This is crucial for tracking system health and maintenance history.

A proactive approach to inspections can preempt system failures and prolong the lifespan of industrial refrigeration systems. Operators should follow these checklists diligently to maintain operational efficiency and safety.

Key Performance Indicators and Efficiency Metrics to Monitor

Maintaining industrial refrigeration systems requires diligent monitoring of various key performance indicators (KPIs) and efficiency metrics. These metrics are critical to ensuring the system operates optimally, minimising downtime, and reducing energy consumption. Here are some of the essential KPIs and efficiency metrics to monitor:

Energy Efficiency Ratios

- Coefficient of Performance (COP): This ratio compares the refrigeration effect produced to the energy consumed. A higher COP indicates a more efficient system.

- Energy Efficiency Ratio (EER): A measure of the cooling capacity in relation to the power input. Higher EER values signify better energy efficiency.

System Performance Metrics

- Refrigeration Capacity: Measures the system’s ability to remove heat at a given time and should be tracked to ensure it meets the required cooling loads.

- Compressor Discharge Temperature: Monitored to prevent overheating, indicative of inefficiencies or system malfunctions.

Operational Consistency Indicators

- Suction Pressure and Temperature: Consistency here is key for maintaining system stability and preventing compressor damage.

- Superheat and Subcooling Levels: Critical for the effective transfer of heat and can indicate proper refrigerant charge and flow.

Maintenance and Reliability Metrics

- Mean Time Between Failure (MTBF): The average time between system failures, used to assess the reliability of the refrigeration system.

- Mean Time to Repair (MTTR): The average time to repair the system, which helps measure the maintainability and speed of response to issues.

Environmental and Safety Measures

- Ammonia Leak Rate: Especially important in systems using ammonia as a refrigerant due to its potential health and safety risks.

- Compliance with Regulations: Adherence to local and international standards, including those for safety, emissions, and energy consumption.

Monitoring these KPIs and efficiency metrics helps to optimise the performance of industrial refrigeration systems, ensuring their reliability, safety, and cost-effectiveness. Ongoing assessment and the use of data analytics can drive continuous improvements and strategic maintenance actions.

Seasonal Maintenance Strategies for Optimal Performance

Maintaining industrial refrigeration systems requires more than just regular upkeep; it involves seasonal strategies to ensure optimal performance throughout the year. As external temperatures fluctuate, these systems must work differently to maintain the desired internal temperatures. For efficient operation and longevity, a seasonal approach is essential.

- Spring Preparation:

- Inspect and clean coils to ensure they’re free of debris after winter.

- Check refrigerant levels as warmer temperatures may affect refrigeration cycles.

- Verify the operation of defrosting components since spring often brings a mix of temperatures.

- Summer Readiness:

- Conduct a comprehensive system check to ensure it can handle peak temperatures.

- Evaluate electrical connections as increased loads from higher usage can cause wear.

- Increase the frequency of inspections, particularly for the condenser and evaporator fans.

- Autumn Adjustments:

- Prepare for colder weather by checking insulation on refrigerant lines.

- Reassess temperature set points since the cooling load may decrease.

- Ensure drainage systems are clear to prevent freezing as temperatures drop.

- Winterisation:

- Inspect heaters and defrost mechanisms more frequently to combat ice accumulation.

- Monitor for any seal or gasket leaks that can be exacerbated by cold temperatures.

- Adjust the economizer cycle to limit the intake of cold external air, thereby reducing energy consumption.

Adapting maintenance activities according to the season not only helps in maintaining system efficiency but also prevents unexpected breakdowns. Each season brings its challenges, and being preemptive in addressing them can lead to seamless system operation year-round.

Troubleshooting Common Issues in Industrial Refrigeration Units

Industrial refrigeration units are complex systems that may encounter a range of issues affecting their performance. Recognizing and troubleshooting these common problems is essential to maintain operational efficiency and prolong the life of the equipment.

- Frost Build-up or Icing: Regular defrost cycles are critical. If excessive frost is noticed, it could indicate a problem with the defrost system or improper door seals. Check defrost frequency settings and door seals for any gaps.

- Fluctuating Temperatures: Temperature inconsistencies can result from poor airflow, a failing compressor, or leaky refrigerant. Ensure the evaporator coils are clean and airflow is unobstructed. Examine the compressor’s operation and check for refrigerant leaks.

- Unusual Noises: Listen for sounds that could indicate loose components, such as bolts or panels, or failing parts, like bearings in motors. Tighten any loose elements and consider replacing any worn-out parts.

- Oil in the Refrigerant Circuit: Oil should circulate with the refrigerant but not accumulate. If you spot oil, it may point to issues with the oil separator or compressor. Inspect these components for functionality.

- High Energy Consumption: Sudden increases in energy use can signify system inefficiencies or malfunctions. Regular maintenance, including cleaning condensers and checking insulation, can minimise this issue.

- Leaks: Refrigerant leaks are both a performance and an environmental concern. Look for oily residues around pipe connections and joints as an indicator of possible leaks and utilise leak detectors to pinpoint the issue.

- Electrical Failures: Electrical components are prone to failure, particularly contactors and relays. Regular inspections can prevent unexpected downtime, ensuring that all electrical connections are tight and in good condition.

Practicing vigilant monitoring and performing routine inspections can often prevent these common issues from escalating into larger problems. When troubleshooting, always prioritise safety, and consult with a professional when in doubt about a system’s specific needs or behaviours.

Advanced Cleaning Techniques for Refrigeration Systems

Maintaining industrial refrigeration systems demands more sophisticated cleaning techniques than residential units require due to their larger size, higher power, and continuous operation. Here are some advanced practices for ensuring the cleanliness and efficiency of these systems:

- Chemical Foaming Agents: Non-abrasive foaming cleaners can remove heavy grime and debris from coils without damaging delicate fins. They are applied with a sprayer, allowing for deep penetration and a thorough clean.

- High-Pressure Cleaning: This involves using water or a mixture of water and detergent at high pressures to dislodge dirt and debris from coils, fans, and other components. High-pressure cleaning should be done carefully to avoid damage to sensitive components.

- Dry Ice Blasting: This method uses dry ice pellets, propelling them at high speeds to clean surfaces. It’s non-conductive, non-corrosive, and leaves no residue, making it ideal for electrical components.

- Robotic Duct Cleaning Systems: These remote-controlled devices can enter ductwork to provide a consistent and thorough clean. Equipped with cameras and cleaning tools, they offer a non-invasive method to clean hard-to-reach areas.

- Ultrasonic Cleaning: Immersion in an ultrasonic bath can be used for small parts. High-frequency sound waves create cavitation bubbles, which effectively remove dirt and contaminants from intricate parts.

When implementing these advanced cleaning techniques, it’s important to ensure that technicians are adequately trained in their use. Following manufacturer specifications and safety guidelines will prevent damage to the refrigeration system and ensure the longevity of the system’s components. Regular and proper cleaning plays a critical role in maintaining energy efficiency, reducing running costs, and extending the lifespan of industrial refrigeration systems.

Upgrades and Retrofits: Keeping Your System Modern and Efficient

In the fast-paced world of industrial refrigeration, the continuous evolution of technology necessitates the implementation of system upgrades and retrofits to ensure peak performance. Staying current is not only about maintaining efficiency but also about capitalizing on the advantages of new, energy-saving technologies that can significantly lower operational costs.

- Assessment of Current System: The first step in upgrading is to thoroughly assess your existing system’s performance. Identify areas that are underperforming or components that are outdated and compare them with the latest systems available in the market.

- Energy-Efficient Components: Replacing older components with energy-efficient alternatives, such as ECM (electronically commutated motors), can yield immediate improvements in power consumption and cost savings. Retrofits must be carefully planned to align with the system’s design specifications and operational requirements.

- Advanced Control Systems: Modern control systems provide precise temperature management and improved automation. Upgrading to sophisticated controls can enhance system reliability and allow for predictive maintenance, thereby reducing downtime and extending the lifespan of the system.

- Heat Recovery Systems: Integrating heat recovery systems can transform waste heat into a valuable resource, reducing the total energy expenditure of the facility. This not only improves efficiency but also advocates for a greener, more sustainable operation.

- Regular Consultations with Experts: To ensure that upgrades and retrofits deliver the desired outcomes, it is crucial to have regular consultations with industrial refrigeration specialists. They can provide insights into the latest trends, technologies, and best practice strategies.

Upgrades and retrofits should be regarded as strategic investments. Keeping your industrial refrigeration system modern and efficient is essential for maintaining a competitive edge and achieving long-term operational success. By regularly updating your system, you can ensure that it remains functional, compliant with regulations, and capable of meeting the changing demands of your business.

Safety Protocols and Compliance in Industrial Refrigeration Maintenance

Ensuring the safety of personnel and compliance with regulations is paramount when maintaining industrial refrigeration systems. Strict protocols must be adhered to, to safeguard against hazards such as refrigerant leaks, mechanical failures, and electrical issues.

- Personal Protective Equipment (PPE): Engineers and technicians should always wear appropriate PPE, including gloves, goggles, and hearing protection, particularly when handling refrigerants or engaging in tasks that may produce flying debris or expose them to loud noises.

- Risk Assessments: Before commencing maintenance work, thorough risk assessments should be conducted. Identifying potential hazards allows the implementation of control measures to mitigate risks.

- Training and Certification: Only qualified personnel with relevant training and certifications should carry out maintenance. This ensures a thorough understanding of the systems in place and the risks involved.

- Adherence to Regulations: Familiarity with local and national regulations governing industrial refrigeration maintenance, such as the F-Gas Regulation in the European Union, is critical. Compliance ensures legal operation and minimizes environmental impact.

- Emergency Protocols: Clearly established emergency procedures must be present to deal with accidental refrigerant releases or other unforeseen incidents. Quick and effective action can prevent injury and equipment damage.

- Lockout-Tagout (LOTO) Procedures: These procedures should be standard practice to ensure energy isolation during maintenance, thereby preventing accidental activation of machinery.

- Regular Audits: Regular auditing of safety protocols ensures ongoing compliance and helps identify areas for improvement.

- Documentation: Detailed records of maintenance and repairs are necessary for ensuring traceability and accountability.

Following these protocols not only creates a safer working environment but also ensures that industrial refrigeration systems are maintained efficiently and responsibly, extending the lifespan of the equipment and maintaining productivity.

Training and Skill Development for Maintenance Personnel

Ensuring that maintenance personnel are adequately trained and skilled is a critical component in the effective upkeep of industrial refrigeration systems. Proper training equips technicians with the necessary knowledge to perform maintenance tasks safely and efficiently.

- Understanding Refrigeration Principles: Technicians must understand the basic principles of thermodynamics and refrigeration cycles. This foundational knowledge aids in diagnosing issues and implementing solutions promptly.

- Safety Training: Given the potential hazards like ammonia leaks or high-pressure systems, safety training is paramount. Personnel should be well-versed in handling refrigerants, understanding Material Safety Data Sheets (MSDS), and following Occupational Safety and Health Administration (OSHA) standards.

- Hands-on Experience: Leveraging on-the-job training allows technicians to apply theoretical knowledge to real-world scenarios. Mentorship programmes pairing experienced technicians with newer staff can also be beneficial.

- Technical Skill Enhancement: Continuous learning opportunities should be provided, including workshops and courses on the latest technologies in refrigeration systems and energy management.

- Accreditation and Certification: Encourage and facilitate the attainment of recognized certifications such as the Industrial Refrigeration Operator Certification or HVAC Excellence Professional Level Certifications.

- Troubleshooting Skills: Regular training exercises that simulate common system failures can enhance diagnostic and troubleshooting abilities.

- Manufacturer Training: Often, manufacturers offer specialist training for specific equipment. Familiarity with the unique characteristics of the installed systems is essential for targeted maintenance.

- Soft Skills: Maintenance roles also require effective communication and documentation skills to ensure that information about maintenance schedules, incidents, and repairs is relayed and recorded accurately.

Maintaining a roster of trained, skilled, and knowledgeable maintenance personnel is an investment in the reliability and longevity of industrial refrigeration systems. It’s a proactive measure that minimizes downtime, ensures operational efficiency, and upholds safety standards across the facility.

Long-term Planning: Budgeting for Repairs and Replacements

Maintaining industrial refrigeration systems is a significant investment that requires foresight and strategic financial planning. It’s essential to prepare and budget for the inevitable repairs and replacements that come with the wear and tear of these complex systems. Long-term planning ensures that businesses can avoid unexpected costs, minimise system downtime, and extend the lifecycle of their equipment.

To effectively budget for future repairs and replacements, the following steps should be considered:

- Assess Life Expectancy: Determine the average lifespan of the refrigeration system and its components based on the manufacturers’ specifications. Regular assessments by qualified technicians can help identify parts that are nearing the end of their useful life.

- Plan for Obsolescence: Keep an eye on industry trends and technological advancements. Parts for older models may become scarce or obsolete, necessitating earlier replacement with more modern, efficient options.

- Create a Reserve Fund: Establish a dedicated savings account or a reserve fund for repairs and replacements. Contributions to this fund should be based on the expected depreciation of the refrigeration system and its components.

- Scheduled Maintenance: Incorporate the costs of routine preventative maintenance into the budget. Regular check-ups can help to identify problems early, potentially reducing the cost of future repairs.

- Review and Adjust: Regularly review your budget and adjust it as necessary to accommodate changes in the system’s performance, energy regulations, or advancements in refrigeration technology.

- Emergency Fund: Consider creating an additional emergency fund for unforeseen circumstances that could necessitate immediate repair or replacement, ensuring minimal disruption to operations.

By anticipating future costs associated with maintaining an industrial refrigeration system, businesses can make informed decisions and allocate their financial resources more effectively. Proactive budgeting for repairs and replacements is crucial for maintaining operational efficiency and ultimately protecting the company’s bottom line.

Leveraging Technology: Automation and Monitoring Systems

In the realm of industrial refrigeration, the adoption of advanced automation and monitoring systems marks a significant move toward efficiency and reliability. Embracing these technologies can lead to substantial improvements in system performance and maintenance practices.

- Automation Systems: These marvels of technology streamline the operation of refrigeration units by regulating temperatures, defrost cycles, and other critical functions automatically. They can adapt to varying load requirements, thereby ensuring optimal performance. Automation reduces the likelihood of human error, minimizes the need for manual intervention, and can significantly reduce operational costs.

- Remote Monitoring: With remote monitoring systems, facility managers have the capability to oversee and control the refrigeration system from any location. This is particularly beneficial for preemptive maintenance, as real-time data about system performance can indicate when parts are beginning to fail or when efficiency is dropping. The immediate access to system alerts and alarms allows for a swift response, potentially preventing minor issues from escalating into major failures.

- Predictive Maintenance: By utilizing data analysis and machine learning, predictive maintenance tools can forecast potential system breakdowns before they occur. These prognostics take into account various operational parameters and historical performance data. Acting on these insights can extend equipment lifespan, preclude unnecessary downtime, and minimize maintenance costs.

- Energy Management: Modern technology provides powerful tools for tracking and managing energy consumption. These systems can identify areas where energy is being wasted and suggest optimization strategies. By incorporating these tools, businesses not only enhance the efficiency of their refrigeration systems but also contribute to sustainability by reducing their carbon footprint.

Incorporating automation and monitoring systems into industrial refrigeration maintenance is not just a trend; it is a strategic approach that ensures systems are running at peak efficiency, with minimized risk of unexpected downtime and optimized energy usage. This technological advancement is an investment that can lead to considerable long-term savings and improved system reliability.

Case Studies: Effective Maintenance in Action

Industrial refrigeration is a critical component in various industries, from food processing to chemical manufacturing. Consistent and proactive maintenance is key to ensuring these systems operate efficiently and effectively. Through case studies, we can explore how businesses have implemented maintenance strategies with substantial positive outcomes.

Dairy Plant Overhauls Cleaning Regimen

A dairy processing plant in the Netherlands faced recurring issues with its refrigeration units. The failure to maintain clean condensers led to poor heat exchange efficiency and increased energy consumption. By adopting a comprehensive cleaning schedule that included regular inspections and the use of non-corrosive cleaning agents, the plant saw a 20% increase in energy efficiency and a significant reduction in downtime.

Meat Storage Facility Implements Predictive Maintenance

In Texas, USA, a sprawling meat storage facility utilized predictive maintenance tools to monitor their refrigeration systems. Installing vibration sensors and infrared thermography allowed them to identify potential failures before they occurred. This approach resulted in a 35% decrease in maintenance-related expenses and prolonged the life of their refrigeration equipment by several years.

Brewery Adopts Real-time Monitoring

A craft brewery in Australia took advantage of real-time monitoring technologies to ensure the optimal performance of their chilling systems. Through the integration of IoT devices that tracked pressure, temperature, and fluid levels, the brewery was able to adjust operations instantaneously. Consequently, they reported a 15% drop in energy usage and a noticeable improvement in product quality.

Through these examples, it’s clear that sustained maintenance efforts can yield tangible benefits. Each case demonstrates that whether through an overhaul of cleaning procedures, predictive maintenance strategies, or real-time monitoring, industries reliant on refrigeration can achieve better efficiency, reduced costs, and improved longevity of equipment.

Conclusion: Best Practices Recap and Future Outlook

Maintaining industrial refrigeration systems is crucial for operational efficiency, longevity, and safety. As we recap the best practices, it is essential to highlight regular inspections and preventive maintenance as the cornerstone of system upkeep. This includes:

- Cleaning heat exchange surfaces to ensure optimal heat transfer and system efficiency.

- Monitoring refrigerant levels and looking for leaks regularly to comply with environmental regulations and maintain system performance.

- Verifying control system accuracy to ensure that temperatures are maintained within desired limits.

- Ensuring all moving parts are well-lubricated to reduce wear and prolong equipment life.

- Checking for proper insulation and door seals to minimize energy loss and prevent moisture ingress.

As we look ahead, the future of industrial refrigeration points towards more sustainable and energy-efficient practices. Innovations such as advanced IoT devices for real-time monitoring, predictive analytics for anticipating faults before they occur, and the ongoing switch to eco-friendly refrigerants are shaping the industry’s future.

Adopting these innovations can lead to significant cost savings, enhanced system reliability, and a reduced carbon footprint. By staying abreast of technological advancements and industry regulations, businesses can position themselves at the forefront of efficient and responsible refrigeration system management.

Ultimately, the synthesis of best maintenance practices with forward-thinking strategies will define competitive, resilient, and environmentally conscious operations in the field of industrial refrigeration.