Industrial refrigeration systems are crucial components in various sectors, providing the necessary cooling and temperature control for processes and storage. These systems differ from commercial or domestic refrigeration in their scale, complexity, and the fact that they are typically tailored to meet specific industry requirements.

Large-scale food production, chemical processing, cold storage warehouses, pharmaceutical manufacturing, and the petrochemical industry are just a few examples where industrial refrigeration is indispensable. These systems ensure that products are kept at precise temperatures to maintain quality, prolong shelf life, and ensure safety.

The key elements that make up industrial refrigeration systems include:

- Compressors: These are the heart of the refrigeration cycle, pumping refrigerant through the system.

- Condensers: These units facilitate the removal of heat from the refrigerant, changing it from a gas to a liquid.

- Evaporators: Responsible for absorbing heat from the product or air within the refrigerated space, thus lowering the temperature.

- Control Systems: These sophisticated components manage the operation of the refrigeration system to maintain desired temperature levels.

- Piping and Valves: The conduits and controls that deliver refrigerant to different parts of the system.

- Insulation: Critical for reducing heat gain from external sources and improving the efficiency of the refrigeration system.

Understanding these elements and their functions is essential for anyone involved in designing, operating, or maintaining industrial refrigeration systems. The systems must be reliable, efficient, and compliant with environmental regulations to ensure uninterrupted operation and minimal impact on the environment.

The Evolution of Industrial Refrigeration Systems

Industrial refrigeration systems have undergone significant transformations since their inception. In the early 19th century, the ice harvesting industry was the primary means of refrigeration, with ice being cut from frozen lakes and rivers and stored in insulated buildings for summer use.

The advent of mechanical refrigeration in the mid-1800s marked a turning point. With the creation of the first practical vapor compression refrigeration system in 1834 by Jacob Perkins, it became possible to have industrial refrigeration without the need for natural ice. Further advancements were made by Carl von Linde, who in 1876 engineered the process of liquefying gases, which led to more efficient and reliable systems.

The early 20th century introduced the widespread use of ammonia as a refrigerant due to its effectiveness and efficiency. Systems continued to grow in size and complexity, catering to industries as diverse as food processing, chemical manufacturing, and pharmaceuticals.

By the mid-20th century, synthetic refrigerants known as chlorofluorocarbons (CFCs) became popular for their chemical stability and safety properties. However, environmental concerns regarding their contribution to ozone depletion led to the Montreal Protocol in 1987, which mandated a global phaseout.

Today, the emphasis on sustainability is driving innovation in industrial refrigeration. The sector is seeing a revival in the use of natural refrigerants such as ammonia and carbon dioxide due to their low environmental impact. Additional advances in electronic control systems, computer modeling, and energy-efficient technologies represent significant strides in the evolution of industrial refrigeration systems. These improvements have led to highly optimized and custom solutions for industrial refrigeration needs, ensuring a balance between operational functionality and environmental stewardship.

Basic Principles of Industrial Refrigeration

Refrigeration is a process that involves removing heat from a substance or space to lower its temperature. The basic principles of refrigeration are based on thermodynamics, specifically the concepts of heat transfer, phase change, and the refrigeration cycle.

- Heat Transfer: Refrigeration systems function by transferring heat from the object or area being cooled to the surrounding environment. This is achieved using three mechanisms of heat transfer: conduction, convection, and radiation.

- Phase Change: The key to refrigeration is the phase change of the refrigerant fluid. When the refrigerant, usually in a liquid state, absorbs heat, it changes phase to a gas. This phase change is an endothermic process, which means that it absorbs heat from the surroundings, effectively cooling the area.

- Refrigeration Cycle: The cycle begins with the refrigerant absorbing heat and evaporating in the evaporator unit. The vapor is then compressed to a higher temperature and pressure by the compressor. From there, the high-pressure hot gas moves to the condenser, where it releases the absorbed heat and condenses back into a liquid. Finally, this liquid passes through an expansion valve, where it experiences a drop in pressure and temperature before returning to the evaporator to begin the cycle again.

The refrigeration process also relies on the principle that gases cool as they expand and heat up as they are compressed—the combined gas law describes this relation. Modern refrigeration systems use this principle in conjunction with various components, such as compressors, condensers, expansion valves, and evaporators, to maintain constant cooling as required by industrial applications.

Understanding these principles helps in the design and maintenance of efficient and effective industrial refrigeration systems. The precise control of the refrigeration cycle is essential in industries such as food processing, chemical manufacturing, and pharmaceuticals, where specific temperature conditions are crucial.

Key Components of an Industrial Refrigeration System

Industrial refrigeration systems are complex networks of components that work in concert to remove heat from a process or space. The effectiveness of such a system depends on the proper function of each component. Below are the key components that make up the backbone of an industrial refrigeration system:

- Compressor: As the heart of the refrigeration system, the compressor’s role is to compress the refrigerant, increasing its pressure, and in the process, moving it through the system.

- Condenser: The heat expelled during the refrigeration process is released into the environment via the condenser. This unit cools the high-pressure gas and transforms it into liquid.

- Evaporator: In the evaporator, the refrigerant absorbs heat from the surrounding area or product being cooled and evaporates, thus reducing temperatures.

- Expansion Valve: This valve regulates the flow of the refrigerant into the evaporator. It allows the high-pressure liquid refrigerant to expand and cool before entering the evaporator.

- Refrigerant: The substance cycled through the system that absorbs and releases heat, making refrigeration possible. Common refrigerants include ammonia, CO2, and hydrofluorocarbons (HFCs).

- Pipes and Tubes: These provide the pathways through which the refrigerant moves between system components.

- Controls and Sensors: These are necessary for the regulation and monitoring of the refrigeration system’s performance. They detect temperatures, pressures, and other critical metrics to maintain operations within safe and efficient parameters.

- Defrosting system: To maintain efficiency, regular defrosting of the evaporator unit is necessary to prevent the build-up of ice and maintain heat transfer efficiency.

- Purging Unit: Particularly in ammonia refrigeration systems, non-condensable gases build up and need to be periodically removed. A purging unit ensures that these gases do not affect the efficiency of the refrigeration cycle.

Each component within an industrial refrigeration system must be meticulously maintained to ensure the entire system’s efficiency and reliability. The failure of one part can have significant ramifications on the whole, emphasizing the importance of each component within the industrial refrigeration process.

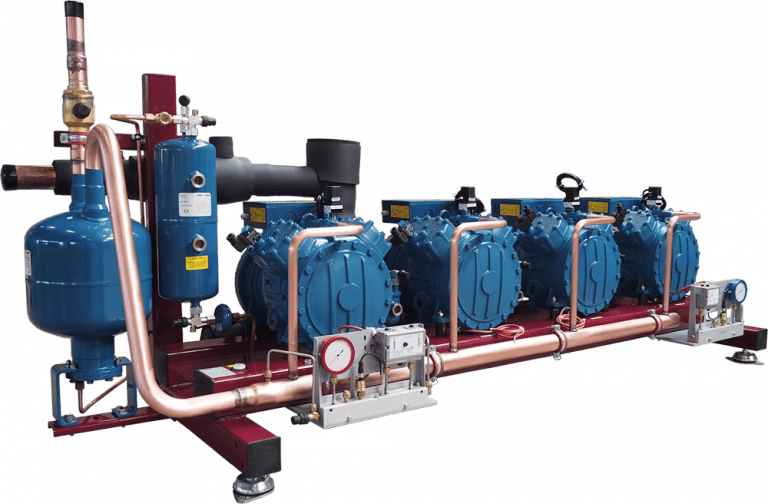

Compressors: The Heart of Refrigeration

Industrial refrigeration systems rely on compressors to perform the crucial task of increasing the temperature and pressure of the refrigerant vapor. In essence, compressors play a central role much like the heart does in the human body – circulating the ‘lifeblood’ of the system, which in this case is the refrigerant. Their primary function is to move the refrigerant throughout the system where it absorbs and discharges heat, thus facilitating the cooling process.

Compressors come in various types, including:

- Reciprocating Compressors: These utilize pistons and work similarly to a car engine. They are known for their high efficiency in small to medium applications.

- Screw Compressors: Consisting of two interlocking screws that compress the refrigerant, screw compressors are used in larger industrial applications due to their capability to manage high refrigerant volumes.

- Centrifugal Compressors: These use a rapidly rotating impeller to transfer energy to the refrigerant and are typically used in very large refrigeration systems.

During operation, compressors undergo a continuous cycle:

- Suction Phase: The refrigerant gas is drawn into the compressor chamber.

- Compression Phase: The gas is compressed, which raises its temperature and pressure.

- Discharge Phase: The high-pressure, high-temperature gas is then expelled to the condenser where it releases heat.

This cycle is indispensable for the refrigeration process because:

- It maintains the necessary pressure differential for the refrigerant to flow.

- It ensures the refrigerant reaches a sufficient temperature and pressure to condense when cooled in the condenser.

- It facilitates the energy transfer that is fundamental to cooling and heating within the system.

Without the compressor, refrigerants would stagnate, and the system’s designed purpose of temperature control would cease to function. Therefore, selecting the right type of compressor for a specific industrial application is critical. The choice depends on factors such as cooling capacity requirements, energy efficiency, cost, and space constraints. Maintaining compressors in prime operating condition through regular inspections and servicing is also vital to ensure the longevity and reliability of an industrial refrigeration system.

Condensers and Their Role in Heat Rejection

In industrial refrigeration systems, the condenser is an integral component, tasked with a crucial role: rejecting heat absorbed during the refrigeration cycle. The refrigerant which has absorbed heat from the cooling space enters the condenser as a high-pressure vapor. Within the confines of the condenser, this vapor is systematically cooled, primarily through the removal of latent heat, causing it to condense into a high-pressure liquid.

- The condenser’s functionality hinges on heat transfer. To achieve this, it often employs a combination of air-cooling or water-cooling mechanisms, or in some cases, a mix of both. In air-cooled systems, fans blow ambient air over the coil or tubes containing the hot refrigerant. Alternatively, in water-cooled condensers, the refrigerant passes through a series of coils that are in turn cooled by water.

- The efficiency of a condenser is measured by its ability to transfer heat to the surroundings. This efficiency is paramount, as it directly affects the energy consumption and performance of the entire refrigeration system.

- Besides transferring heat, condensers also play a pivotal role in maintaining the pressure within the refrigeration system. By regulating the state and pressure of the refrigerant, the condenser ensures the proper functioning of the system’s compressors and evaporators.

- Maintenance of condensers is key to system longevity. Over time, the heat rejection capability can degrade due to scaling, fouling, or physical damage. Regular cleaning and inspections are necessary to sustain optimal performance.

The role of condensers in heat rejection illustrates the broader theme of balance in an industrial refrigeration system. They are not standalone devices; rather, they are part of an intricate network where each element’s efficiency influences the overall system. Effective heat rejection by condensers ensures that the refrigeration cycle continues to operate smoothly and efficiently, providing precise temperature control, which is indispensable in many industrial processes.

Evaporators – Achieving the Cooling Effect

Evaporators are critical components in industrial refrigeration systems, responsible for the actual cooling effect. They come into play after refrigerants absorb heat from the space or product being cooled and change from a liquid to a gas in the refrigeration cycle.

Function of Evaporators

- Evaporators facilitate the process where the liquid refrigerant, having low pressure due to passing through an expansion valve, absorbs heat and evaporates.

- During evaporation, the refrigerant extracts heat from the surrounding environment, significantly cooling down the immediate area.

- This effect is used to maintain the desired low temperatures within refrigeration spaces or to cool products to their required preservation temperatures.

Types and Adaptations

- Various types of evaporators are utilized depending on the specific needs of the industrial refrigeration system:

- Bare tube evaporators are common in small systems.

- Plate evaporators provide efficiency in space utilization.

- Finned evaporators increase the heat transfer surface area for more effective cooling.

- In large-scale industrial applications, multiple evaporators can be used in series or parallel setups, enhancing the system’s cooling capacity and reliability.

Challenges and Solutions

- A key challenge with evaporators is ice formation, which can insulate the coils and reduce efficiency. Defrost systems, such as hot gas or electric, are regularly engaged to melt the ice.

- Ensuring proper airflow and regular maintenance helps prevent the efficiency of evaporators from diminishing over time.

Through their role of absorbing heat and lowering temperatures, evaporators are integral to the functionality of industrial refrigeration systems. The selection and maintenance of the right type of evaporator are vital to achieving the cooling effect necessary for industrial applications.

Expansion Valves: Controlling Refrigerant Flow

In the intricate workings of industrial refrigeration systems, the expansion valve plays a pivotal role in regulating refrigerant flow into the evaporator. Essentially, this component is tasked with metering the precise amount of refrigerant based on the cooling demand. Serving as a critical checkpoint, it helps maintain the balance and efficiency of the overall refrigeration cycle.

There are different types of expansion valves, each suited for specific applications and refrigeration needs:

- Thermostatic Expansion Valves (TXVs): These valves adjust the flow of refrigerant using a sensor bulb that monitors the temperature of the refrigerant leaving the evaporator. TXVs are responsive and can adapt to varying loads, making them a popular choice in systems where the cooling load fluctuates.

- Electronic Expansion Valves (EXVs): Controlled by sophisticated electronics, EXVs offer precise control over refrigerant flow. They are often used in conjunction with modern control systems that can optimize performance based on real-time data.

- Automatic Expansion Valves (AXVs): AXVs regulate the refrigerant flow by maintaining a constant superheat at the evaporator outlet. These valves are simpler in design and generally used in systems with a constant load.

- Capillary Tubes: Capillary tubes are often used in smaller systems and serve as a fixed orifice device to control the flow of refrigerant without moving parts, relying on pressure drop and refrigerant properties.

The expansion valve has a direct impact on the system’s pressure and temperature dynamics. By controlling the flow of refrigerant:

- It ensures that the evaporator operates efficiently by preventing both underfeeding and overfeeding of refrigerant.

- It aids in achieving desired temperature levels for the refrigeration process.

- It helps in maintaining superheat, thereby protecting the compressor from liquid refrigerant return, which can cause damage.

Consequently, the correct selection, installation, and maintenance of expansion valves are paramount to ensure optimal performance and longevity of industrial refrigeration systems.

The Importance of Insulation in System Efficiency

Industrial refrigeration systems form the backbone of industries requiring precise temperature controls, such as food processing, chemicals, and pharmaceuticals. Insulation in these systems is critical in maintaining efficiency and operational effectiveness. Proper insulation serves various essential functions:

- Reduces Heat Gain: By preventing ambient heat from entering the system, insulation ensures that the refrigeration unit does not overwork to maintain the desired temperatures. This is particularly vital for components such as pipes and cold storage tanks.

- Minimizes Energy Costs: Effective insulation directly translates to lower energy consumption. When refrigeration systems are well-insulated, they require less power to keep the stored products at the ideal temperature, resulting in significant cost savings.

- Limits Moisture Infiltration: Moisture can be a pervasive issue, leading to ice buildup and system corrosion. Insulation acts as a barrier, keeping moisture away from cold surfaces and thus preventing the associated complications.

- Extends System Lifespan: By reducing the stress on refrigeration components, insulation aids in extending the overall lifespan of the system. It enables components to function within their intended operational parameters, thus avoiding wear and tear from excessive load.

- Enhances Safety: Proper insulation reduces the risk of condensation, which can lead to slippery conditions around the refrigeration system. Furthermore, it can prevent the freezing of nearby equipment or piping, ensuring a safer working environment.

In summary, insulation is not simply an add-on but a fundamental component that warrants as much consideration as any mechanical element in industrial refrigeration systems. Choosing the right insulation material and ensuring it is correctly installed and maintained can make a substantial difference in performance, safety, and cost-efficiency.

Refrigerants: Types and Their Environmental Impact

Refrigerants are critical components in industrial refrigeration systems, essential for heat transfer and maintaining low temperatures. There are several types of refrigerants, each with unique properties and environmental impacts.

Types of Refrigerants:

- CFCs (Chlorofluorocarbons): Once common, these are now rarely used due to their high Ozone Depletion Potential (ODP).

- HCFCs (Hydrochlorofluorocarbons): They have lower ODP than CFCs but are still harmful to the ozone layer and are being phased out under international agreements.

- HFCs (Hydrofluorocarbons): HFCs do not deplete the ozone layer but have high Global Warming Potential (GWP), contributing significantly to climate change.

- Natural Refrigerants: These include substances like ammonia, carbon dioxide, and hydrocarbons (such as propane and butane). They have low environmental impact in terms of both ODP and GWP.

- HFOs (Hydrofluoroolefins): HFOs are a newer generation of refrigerants with much lower GWP, designed to replace HFCs in many applications.

Environmental Impact:

The environmental impact of refrigerants hinges greatly on two key factors: the Ozone Depletion Potential (ODP) and the Global Warming Potential (GWP).

- ODP: Refers to the degree to which a substance can catalyze the breakdown of ozone molecules in the stratosphere.

- GWP: A measure of how much heat a substance can trap in the atmosphere relative to carbon dioxide over a specific period.

CFCs and HCFCs, with high ODP, have been largely banned under the Montreal Protocol. HFCs, while ozone-friendly, have been under scrutiny for their high GWP, leading to the development of the Kigali Amendment to the Montreal Protocol, aiming to reduce their use. Natural refrigerants and HFOs represent promising alternatives with much lower environmental risk profiles. As the regulatory landscape evolves, the push towards eco-friendly refrigerants grows, changing the dynamics of industrial refrigeration practices to mitigate climate change and protect the ozone layer.

Control Systems and Automation in Industrial Refrigeration

In the realm of industrial refrigeration, control systems and automation play a pivotal role in ensuring operational efficiency, reliability, and safety. These systems allow for precise monitoring and regulation of temperatures, pressures, and other critical parameters within the refrigeration cycle. The integration of advanced control technologies can optimize the performance of compressors, condensers, evaporators, and other key components.

- Temperature Control: The core of refrigeration is maintaining the desired low temperatures. Automation systems maintain consistent temperature levels within narrow tolerances, adapting to varying loads and environmental conditions. Sensors placed strategically throughout the system feed real-time data to a central control unit, which makes adjustments as necessary.

- Compressor Control: Compressors are essential for increasing the refrigerant pressure and moving it through the system. Control systems adjust the operation of the compressors based on demand, reducing wear and enhancing energy efficiency. Variable frequency drives (VFDs), for instance, regulate the speed of the compressor motors, significantly cutting down energy consumption.

- Safety Protocols: Automated safety checks are embedded within the control systems to prevent overpressure, overloading, and other potential hazards. These protocols initiate emergency shut-down procedures when they detect anomalies, protecting both the system and personnel.

- Energy Management: By adjusting the refrigeration cycle for optimal efficiency, control systems manage energy use meticulously, leading to cost savings and reduced environmental impact. The automation software can compile performance data over time, providing insights that can be used to further refine energy usage.

- Remote Monitoring and Diagnostics: Modern industrial refrigeration systems often include remote monitoring capabilities, allowing operators to oversee system performance from off-site locations. This convenience facilitates early detection of issues, pre-emptive maintenance, and expedited troubleshooting.

In conclusion, control systems and automation function as the nervous system of industrial refrigeration, coordinating various components and processes to maintain seamless operation. They bring about far-reaching benefits, from energy conservation to improved product quality, underscoring their indispensable role in the infrastructure of industrial cooling systems.

Maintenance and Safety Considerations

Proper maintenance is vital for the efficient and safe operation of industrial refrigeration systems. These systems are complex and require regular checks to ensure that each element is functioning correctly.

- Regular Inspection: Components such as compressors, condensers, evaporators, and valves need regular inspection to prevent failure. Identifying issues like leaks, corrosion, or wear and tear early can prevent costly repairs and downtimes.

- Cleaning Routines: To maintain thermal efficiency, regular cleaning of the heat transfer surfaces is necessary. This includes the condenser coils and the evaporator coils, which can accumulate dirt and debris, reducing the system’s effectiveness.

- Lubrication: Moving parts within the system, such as compressor bearings and fans, require proper lubrication to reduce friction and prevent overheating or failure.

- Refrigerant Management: Monitoring refrigerant levels is critical. Low refrigerant levels can stress the compressor while overcharging can lead to inefficient operation and potential safety hazards. Additionally, using the correct type of refrigerant is essential to comply with environmental regulations.

- System Checks: Regular system performance evaluations can help diagnose potential inefficiencies. This includes checking temperature settings, calibrating controls, and assessing insulation integrity.

- Safety Protocols: Adhering to safety protocols is paramount. This involves training personnel on proper operation procedures, ensuring that safety and emergency shut-off systems are functional, and conducting periodic safety audits.

- Emergency Preparedness: Having a plan in place for potential system breakdowns can minimize risks. This includes keeping spare parts on hand and establishing procedures for rapid troubleshooting and repairs.

- Compliance with Regulations: Staying updated with and adhering to local and international regulations related to refrigeration systems can avoid legal issues. This includes regulations regarding refrigerant usage, energy efficiency, and occupational safety standards.

It’s crucial to document all maintenance activities. Keeping records of inspections, repairs, and replacements helps in tracking the system’s history and planning future maintenance. It also serves as evidence of compliance with regulations and standards in the industrial refrigeration industry.

Advancements in Industrial Refrigeration Technology

Industrial refrigeration technology has undergone significant transformations driven by the need for energy efficiency, environmental sustainability, and improved reliability.

- Eco-Friendly Refrigerants: Modern systems are increasingly using natural refrigerants like ammonia, CO2 (carbon dioxide), and hydrocarbons instead of HFCs (hydrofluorocarbons) to reduce environmental impact and comply with stringent regulations.

- Advanced Compressors: The advent of screw and scroll compressors has led to systems that are not only quieter but also more energy-efficient. They provide a more precise control of the refrigeration cycle, maximizing performance.

- Variable Frequency Drives (VFDs): VFDs allow compressors and fans to operate at variable speeds, reducing energy consumption during lower demand periods. This has led to significant improvements in energy efficiency and cost savings for industrial refrigeration.

- Smart Controls: Integration of intelligent control systems enables real-time monitoring and automation of the refrigeration process. These systems can optimize performance, predict maintenance needs, and reduce downtime.

- Heat Recovery Systems: By harnessing the excess heat generated from refrigeration processes, these systems can provide heating for facilities or hot water generation, further improving energy efficiency.

- Improved Insulation: Advances in insulation materials and methodologies have significantly enhanced the thermal performance of refrigeration systems, ensuring that temperatures are maintained more consistently and with less energy.

- Compact Modular Design: Newer units are designed to be compact and modular, providing flexibility in installation and maintenance. This design shift makes it easier to expand or adapt systems as requirements change.

These advancements contribute to a more sustainable, cost-effective, and functional industrial refrigeration infrastructure that can adapt to the evolving needs of diverse industries such as food processing, pharmaceuticals, and cold storage logistics.

Future Trends in Industrial Refrigeration: Sustainability and Innovation

The refrigeration industry stands at the precipice of transformation, driven by the urgent demands of sustainability and the unyielding march of innovation. Key trends shaping the future of industrial refrigeration systems include:

- Eco-Friendly Refrigerants: As concern for the environment deepens, the shift away from high Global Warming Potential (GWP) refrigerants to alternatives with lower environmental impact continues. Natural refrigerants such as ammonia, CO2, and hydrocarbons are gaining traction, not just for their reduced GWP but also for their energy efficiency.

- Energy-Efficient Systems: Industrial refrigeration is moving towards more energy-efficient systems, employing advanced technologies like variable speed drives and energy management systems. These innovations ensure that systems use only as much power as needed, aligning with global initiatives to reduce energy consumption.

- Smart Technology Integration: The integration of smart technologies such as Internet of Things (IoT) sensors and artificial intelligence (AI) improves the monitoring and automation of refrigeration systems. These intelligent systems can predict maintenance needs, optimize performance, and reduce downtime.

- Heat Recovery Systems: Innovations in heat recovery allow waste heat from refrigeration to be repurposed, typically for water heating or space heating, further enhancing the system’s overall efficiency and sustainability.

- Modular Systems: The future of industrial refrigeration also includes the development of modular systems that can be easily scaled up or down based on demand, allowing for flexibility and adaptation to various industrial requirements.

The evolution of industrial refrigeration is a testament to the sector’s commitment to embracing eco-friendly practices without compromising on the core functionality and reliability expected from these systems. These advancements signal a robust response to global environmental challenges, showcasing an industry poised to cool the future with sustainability at its heart.

Conclusion: The Integral Role of Refrigeration in Industry

Industrial refrigeration systems are critical drivers of modern industry. They play a vital role in maintaining the quality and safety of perishable products, allowing for extended storage, transportation across vast distances, and availability out of season. As such, refrigeration is an indispensable component in sectors like food processing, pharmaceuticals, and petrochemicals.

- In the food industry, refrigeration ensures that produce, dairy, meats, and frozen goods remain safe for consumption by slowing bacterial growth. This is not just about preserving freshness, but also about protecting public health.

- The pharmaceutical industry relies on precise refrigeration for the stability and efficacy of medications and vaccines. In particular, the recent global focus on vaccine storage highlights the importance of sophisticated refrigeration units capable of maintaining ultra-low temperatures.

- In the petrochemical sector, refrigeration is crucial for the safe storage and processing of chemicals. Cooling systems help prevent accidents and manage the complex reactions that occur during petrochemical processing.

The advances in refrigeration technology have also improved energy efficiency, reducing the carbon footprint of industries. Modern control systems and refrigerants are designed to minimize environmental impact while enhancing operational efficiency.

To summarize, refrigeration is a cornerstone of several key industries, ensuring product integrity, safety, and sustainability. The role of refrigeration in industry is not just integral but continues to evolve with technological advancements, addressing both consumer needs and environmental concerns.