Maximizing Cold Room Efficiency

Here’s an overview:

- Introduction to Innovative Cold Room Designs

- Assessing Space Requirements for Effective Cold Room Layout

- Material Selection and Insulation Techniques for Enhanced Performance

- The Role of Cutting-Edge Refrigeration Technology in Cold Room Efficiency

- Incorporating Smart Storage Solutions in Cold Room Design

- Energy-Efficient Practices for Sustainable Operation

- Case Studies: Successful Implementations of Innovative Cold Room Designs

- Conclusion: Future Directions in Cold Room Design and Optimization

Introduction to Innovative Cold Room Designs

In the realm of cold storage, innovative designs are transcending traditional models to deliver enhanced efficiency. These cutting-edge refrigeration panels and cold room solutions are tailored to diverse industry needs—from food preservation to pharmaceutical storage. They are equipped with advanced insulation materials, smart monitoring systems, and energy-efficient components. The meticulous design process ensures maximum thermal performance, thereby reducing operational costs and environmental impact. These contemporary designs not only prioritize energy efficiency but also incorporate modular features for easy expansion and adaptive reconfiguration, catering to growth and changing market demands.

Assessing Space Requirements for Effective Cold Room Layout

When designing a cold room, understanding spatial needs is paramount. An effective layout optimizes storage while maintaining steady airflow around refrigeration panels. Consider the following:

- Inventory Size: Align cold room dimensions with inventory volume, allowing for expansion.

- Workflow: Ensure efficient movement space for staff, minimizing obstructions for safety.

- Cooling Capacity: Match the refrigeration system to the room’s volume for uniform temperature control.

- Regulatory Compliance: Accommodate space for compliance with health and safety regulations.

- Panel Selection: Opt for panels that offer high insulation value without excessive thickness, preserving internal space.

Material Selection and Insulation Techniques for Enhanced Performance

Choosing the right materials for refrigeration panels is crucial for optimizing cold room efficiency. High-performance insulation materials such as polyurethane (PU) and polystyrene (PS) are common due to their superior thermal resistance. Innovations in vacuum insulation panels (VIPs) provide even greater insulation values, albeit at a higher cost. Layering materials with reflective coatings can further reduce thermal transfer.

Insulation techniques include:

- Continuous Insulation: Avoiding thermal bridging by ensuring insulative material is unbroken and continuous.

- Proper Sealing: Employing airtight seals around panel edges to prevent air infiltration.

- Adaptive Thickness: Customizing insulation thickness based on the cold room’s operational temperature requirements.

- Advanced Joints: Using mechanical fastening systems that maintain insulation integrity at panel joints.

Selecting cutting-edge materials and employing these insulation techniques significantly improves cold room performance, reducing energy consumption and costs.

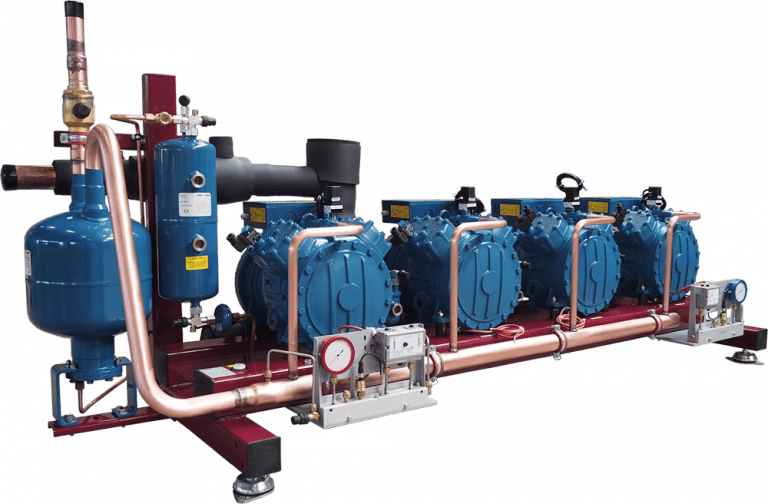

The Role of Cutting-Edge Refrigeration Technology in Cold Room Efficiency

Innovative refrigeration technology significantly enhances cold room efficiency. This technology includes advanced compressors that respond dynamically to cooling demands, thus conserving energy. Variable speed fans adjust based on interior temperature, further reducing electrical consumption.

- Smart Controls: Automation systems now enable precise temperature regulation, preventing energy wastage due to manual errors or oversight.

- High-Performance Insulation: Modern panels incorporate vacuum or aerogel insulation, delivering superior thermal resistance with thinner profiles, minimizing space loss.

- Eco-Friendly Refrigerants: New refrigerants with lower global warming potential not only safeguard the environment but also improve the overall efficiency of refrigeration cycles.

In essence, current refrigeration advancements are pivotal in optimizing cold room operations, cutting costs, and reducing environmental impacts.

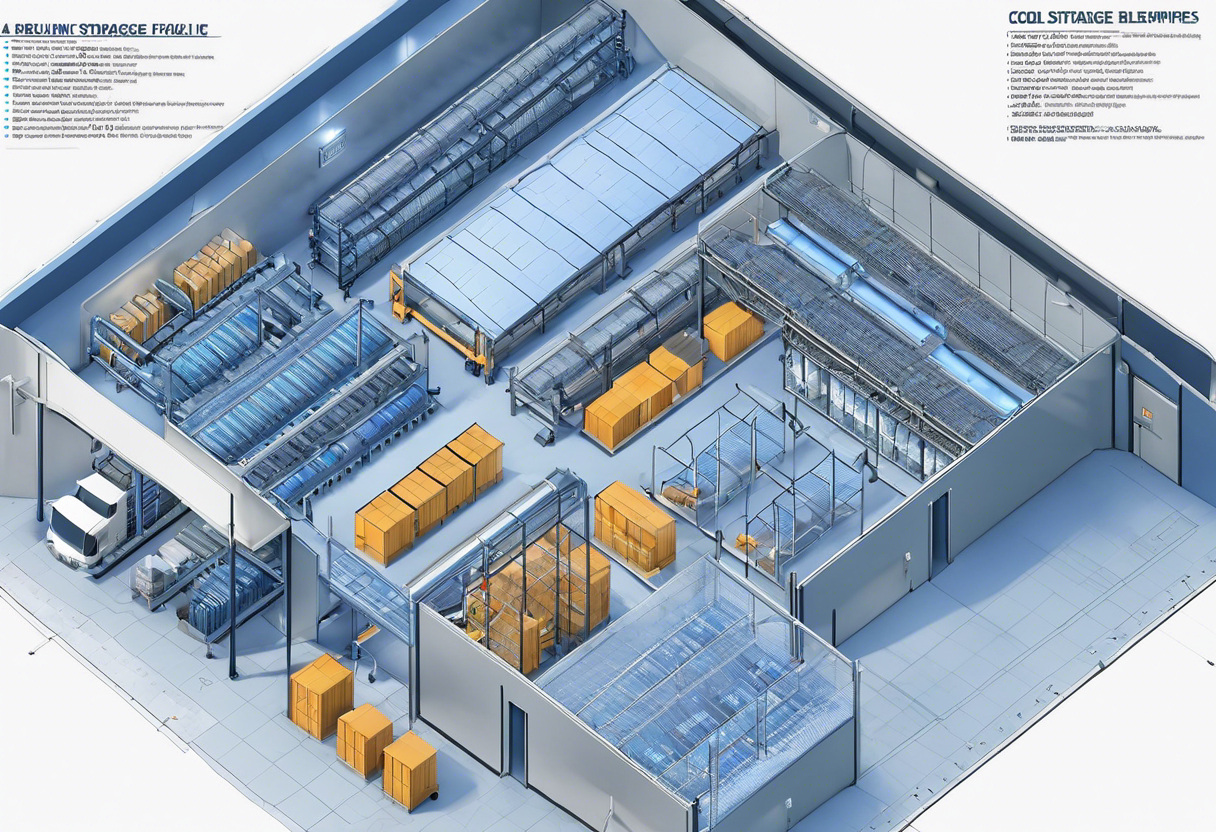

Incorporating Smart Storage Solutions in Cold Room Design

Effective cold room operation hinges on thoughtful storage solutions that maximize space without impeding air circulation. Implementing sliding shelves and modular stacking systems can greatly enhance the capacity and efficiency of a cold room. Additionally, considering the use of mobile racking can reduce the cold room footprint, while still maintaining product accessibility. Engineers and designers are integrating sensors and automated inventory systems, ensuring that the temperature is uniformly maintained and products are easily traceable. Such smart storage systems are critical for optimizing energy use and reducing operational costs. Incorporating these elements into refrigeration panel design can result in a superior cold room setup that is efficient, scalable, and more accessible.

Energy-Efficient Practices for Sustainable Operation

- Regular maintenance of cold room walls and refrigeration panels ensures optimal insulation and minimal thermal leakage.

- Employing smart defrosting systems reduces energy consumption by scheduling defrost cycles during off-peak hours.

- Upgrading to LED lighting within the cold room not only cuts down on energy usage but also generates less heat, relieving the refrigeration system.

- Installing variable speed drives for compressors and fans allows the refrigeration system to operate more efficiently, adjusting to the actual cooling demand.

- Implementing energy management systems can monitor energy usage and identify areas for efficiency improvements and potential cost savings.

Case Studies: Successful Implementations of Innovative Cold Room Designs

- Pharmaceutical Storage Facility – A leading pharmaceutical company integrated vacuum insulated panels (VIPs) in their storage, achieving a marked improvement in temperature control while reducing energy consumption by 30%.

- Regional Distribution Center – By adopting a combination of polyurethane (PUR) and polystyrene (EPS) foam panels, this center enhanced its thermal efficiency and increased shelving space due to thinner panel designs.

- Specialty Food Warehouse – Incorporating smart-monitoring refrigeration panels allowed for real-time temperature monitoring and adjustments, resulting in a 25% reduction in spoilage and a 20% cut in energy costs.

- Agricultural Co-op Cold Storage – With the installation of solar-powered refrigeration panels, this co-op maximized sustainability and saw a 50% decrease in their energy bills.

Conclusion: Future Directions in Cold Room Design and Optimization

As innovations continue, the future of cold room design focuses on sustainability, energy efficiency, and advanced technological integration. Upcoming trends include:

- Utilization of AI and IoT for real-time monitoring and predictive maintenance.

- Implementation of phase change materials (PCMs) for better thermal regulation.

- Emphasis on modular designs that offer scalable solutions for varying business sizes.

- Increased use of eco-friendly refrigerants to minimize environmental impact.

- Incorporation of smart defrosting systems to reduce energy consumption.

Continued research and development in these areas will lead to optimized cold storage solutions, fulfilling the demands of diverse industries while conserving resources and enhancing operational efficiency.