Proper onion cold storage is crucial for maintaining their quality and longevity. Optimal conditions involve:

- Temperature: Onions prefer a consistent temperature range, typically between 0°C and 4°C (32°F to 40°F).

- Humidity: A relative humidity of 65% to 70% is considered ideal.

- Ventilation: Adequate air circulation is essential to prevent moisture buildup and minimize spoilage risks.

- Light: Onions should be stored in the dark to deter sprouting and the development of strong flavors.

- Separation: They must be kept away from other produce to prevent flavor transfer and absorption of ethylene gas, which can accelerate their deterioration.

Understanding these parameters is vital to configuring cold storage facilities and ensuring the preservation of onion quality during prolonged storage periods.

Benefits of Proper Onion Cold Storage

- Extended Shelf Life: By maintaining optimal temperatures and humidity levels, onions can be preserved for longer periods, reducing spoilage and waste.

- Quality Maintenance: Proper cold storage conditions help keep the onions firm and flavorful, preserving their quality.

- Economic Advantage: Reduction in spoilage translates to decreased losses and increased profitability for farmers and retailers.

- Year-Round Availability: Efficient cold storage enables a consistent supply of onions throughout the year, regardless of the season.

- Reduction of Sprouting: Cold storage inhibits sprouting, ensuring that onions remain dormant and fresh until they reach the consumer.

- Disease Management: Storing onions in a controlled environment can minimize the risk of disease and rot, which are common at improper temperatures.

- Improved Safety: Storing onions at proper temperatures reduces the probability of bacterial growth, contributing to food safety.

Proper onion cold storage is crucial for maintaining product integrity from farm to table.

Analyzing Different Cold Storage Technologies

When preserving onions, various cold storage technologies warrant consideration.

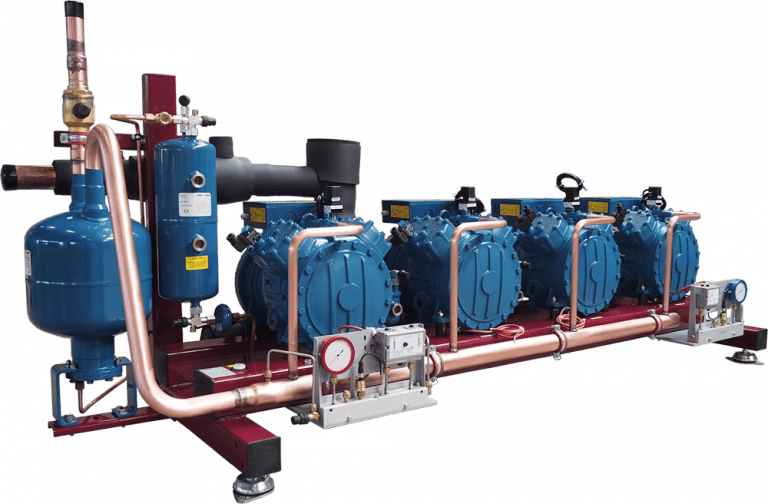

- Mechanical Refrigeration utilizes compressors and refrigerants to maintain precise temperature and humidity levels.

- Cryogenic Cooling involves the application of extremely cold substances such as liquid nitrogen to reduce temperatures rapidly.

- Evaporative Cooling relies on the evaporation of water to cool air, suitable for regions with low humidity.

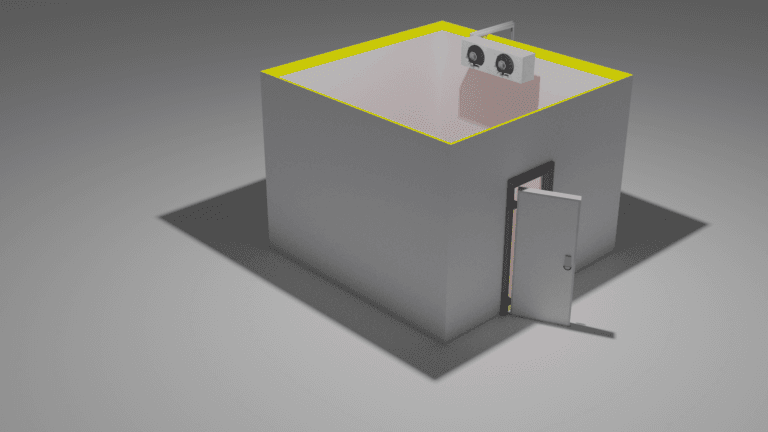

- Thermally Insulated Cold Rooms use materials with high insulation properties to minimize heat exchange with the external environment.

Each system has its advantages and constraints, with factors such as cost, energy efficiency, and the specific storage needs of onions, such as optimal temperature range and ventilation requirements, playing a critical role in determining the most appropriate technology.

Key Factors Influencing Onion Shelf-life

Onion shelf-life is significantly affected by several key factors:

- Temperature Control: Optimal cold storage temperatures range between 0-4°C to slow down respiration and enzymatic activities.

- Humidity Management: A relative humidity of 65-70% is ideal to prevent loss of moisture and to maintain firmness.

- Air Circulation: Proper ventilation is essential to dissipate heat and ethylene gas produced by onions, thus reducing the risk of rot.

- Hygiene Practices: Clean storage environments minimize the incidence of pathogens and pests that can spoil onions.

- Ethylene Exposure: Exposure to ethylene from other produce can accelerate ripening and spoilage, so isolation is critical.

- Varietal Differences: Some onion varieties inherently possess longer shelf-life due to their genetic makeup and physical characteristics.

Design Considerations for Onion Cold Storage Facilities

When planning onion cold storage facilities, several factors must be meticulously considered to ensure optimal preservation of produce:

- Temperature and Humidity Control: Onions require specific temperature ranges between 0-4°C with relative humidity levels of 65-70% to minimize sprouting and rotting.

- Ventilation: Adequate ventilation is essential to remove ethylene gas and prevent fungal growth.

- Racking Systems: Adjustable racking systems allow for efficient space utilization and air circulation.

- Insulation: Proper insulation minimizes temperature fluctuations and energy costs.

- Redundant Systems: Implementing backup cooling systems prevents spoilage during equipment failure.

- Integrated Monitoring: Real-time environmental monitoring and alarm systems enable immediate response to deviations in storage conditions.

Temperature and Humidity Control Strategies

Effective onion cold storage demands maintaining specific temperature and humidity levels. Optimum temperatures generally range between 0-4°C, inhibiting sprouting and decay. For humidity, a steady 65-70% is advisable, preventing weight loss from dehydration and minimizing microbial growth. Implementing these control strategies involves:

- Utilizing high-quality insulation to sustain stable internal conditions.

- Installing accurate thermostats and hygrometers to monitor the environment continuously.

- Integrating automated climate control systems that adjust temperature and humidity levels as required.

- Ensuring proper air circulation through well-designed ventilation systems, helps in uniform distribution of cool air and maintaining desired humidity.

- Regular maintenance of refrigeration units to prevent fluctuations that could lead to spoilage.

Onion Storage Solutions for Small-Scale Producers

For small-scale onion producers, effective storage is critical to maintain the quality of their harvest. They can adopt the following practices:

- Ventilated Storage Areas: Create well-ventilated spaces where air can circulate around the onions, as good airflow is essential for longevity.

- Mesh Bags or Netting: Store onions in mesh bags or utilize netting to hang them, which facilitates air movement and reduces rot.

- Consistent Temperature Regulation: Maintain a storage area with a consistent temperature, ideally between 30-40°F (-1-4°C) to prevent sprouting and spoilage.

- Shelving Systems: Use wooden or plastic shelving units to keep onions off the ground, reducing the risk of moisture-related decay.

- Regular Inspections: Conduct regular checks on stored onions to remove any that are starting to spoil to protect the rest of the crop.

Advanced Cold Storage Solutions for Large Scale Operations

Large-scale operations require sophisticated cold storage solutions to maintain the quality and longevity of stored onions. These facilities often incorporate:

- Automated Environmental Control Systems: These systems monitor and adjust temperature, humidity, and airflow to ensure optimal storage conditions.

- Energy-Efficient Refrigeration: Implementing industrial-grade refrigeration units that use less energy helps reduce operational costs.

- Scalable Storage Designs: Modular storage units can be expanded easily to accommodate growing inventory needs.

- Real-Time Monitoring: Sensors provide live data on storage conditions, allowing for immediate adjustments and alerts for any deviations.

- Inventory Management Software: Integration with advanced software helps in tracking stock levels and predicting future storage requirements, enhancing operational efficiency.

Innovative Onion Packaging Techniques for Extended Freshness

The quest for prolonged freshness of onions has led to the development of several innovative packaging techniques:

- Modified Atmosphere Packaging (MAP): This approach adjusts the concentration of gases within packaging, slowing down the ripening process and inhibiting decay.

- Vacuum Packaging: By removing air, this method minimizes oxidation and the growth of aerobic bacteria, extending shelf life.

- Antimicrobial Coatings: Packaging with antimicrobial substances can limit bacterial growth, keeping onions fresh for a longer duration.

- Ethylene Absorbers: Including ethylene-absorbing sachets within onion packaging helps delay the aging process by neutralizing the ripening hormone.

- Active Packaging Systems: These systems actively regulate moisture, gas composition, or have other properties that extend storage life.

Utilizing these advanced packaging solutions, suppliers and retailers can reduce spoilage and manage onion freshness optimally during storage and transport.

Cost-Benefit Analysis of Cold Storage Investments

Investing in cold storage for onions involves examining both the immediate and long-term financial implications. Businesses must consider the following:

- Initial costs: Construction, refrigeration units, insulation materials, and technology for temperature control.

- Operational expenses: Energy consumption, maintenance, staff training, and repairs.

- Benefits: Reduced spoilage, extended marketing period, better price control, and higher-quality produce.

- Return on investment (ROI): Increased saleable product volume and reduced losses typically lead to favorable ROI over time.

- Risk factor considerations: Commodity price fluctuations, energy cost variability, and technological obsolescence risks.

Detailed cost-benefit analysis ensures informed decision-making for sustainable cold storage investments.

Maintenance and Operation of Onion Cold Storage Systems

To ensure the longevity and efficiency of onion cold storage systems, regular maintenance is crucial. Operators should:

- Monitor Temperature and Humidity: Constantly check sensors and calibrate them to maintain the optimal storage environment for onions.

- Inspect Cooling Units: Perform routine checks on condensers, compressors, and evaporators for signs of wear or damage.

- Maintain Airflow: Keep ventilation systems clear to ensure consistent air circulation, preventing the development of hot spots.

- Clean Regularly: Schedule cleaning to remove dirt and debris, which can impede system efficiency.

- Check Insulation: Inspect insulation for damage or moisture infiltration that can lead to energy loss.

- Test Back-up Systems: Regularly test generators or other emergency systems to ensure functionality in case of power outages.

- Train Personnel: Provide ongoing training to staff on proper operation procedures and safety protocols.

The Future of Onion Cold Storage Innovations

The evolution of onion cold storage is expected to focus on sustainability, energy efficiency, and technological integration. Innovations may include:

- Advanced Refrigeration Systems: These would use alternative, eco-friendly refrigerants and solar energy to reduce the carbon footprint.

- Real-time Monitoring and Control: IoT sensors could provide insights on temperature, humidity, and gas composition, allowing for remote management.

- Robotics and Automation: The use of robotics for sorting and handling onions could streamline operations and minimize product damage.

- Thermal Energy Storage: This technology would enable the storage of cold energy during off-peak hours to improve efficiency and cost-effectiveness.

- Smart Packaging: Packaging solutions that extend shelf life and monitor freshness could integrate with cold storage systems to optimize conditions for onions.

- Modular and Mobile Units: Portable cold storage could offer flexibility for variable demand and reduce transportation needs, preserving quality till market.

Each advancement aims to enhance the longevity and quality of stored onions while also prioritizing environmental concerns and resource optimization.