Introduction to Poultry Products Cold Storage

Cold storage plays a critical role in maintaining the quality and safety of poultry products. Immediate and proper chilling after processing is essential in preventing the growth of harmful bacteria and extending the shelf life of products. Various factors must be considered when organising and managing cold storage for poultry, including temperature regulation, packaging, humidity control, and storage duration.

Temperature Regulation

Maintaining the correct temperature is pivotal for inhibiting bacterial growth in poultry products. Ideal storage temperatures for poultry are:

- Fresh Poultry: Kept between 0°C and 2°C.

- Frozen Poultry: Stored at -18°C or lower to ensure product safety and quality.

Temperature stability is crucial. Any fluctuation may cause partial thawing, leading to microbial proliferation and spoilage.

Packaging

Proper packaging materials are necessary to protect poultry products in cold storage. Effective packaging:

- Prevents Contamination: Seals products from external pollutants and bacteria.

- Reduces Moisture Loss: Minimizes dehydration and preserves texture.

- Protects Against Freezer Burn: Ensures prolonged quality by preventing unwanted moisture loss.

Vacuum-sealed packaging is often recommended for its efficiency in maintaining product integrity during freezing and storage.

Humidity Control

Humidity control is essential to prevent moisture loss and maintain the quality of poultry products. An optimal relative humidity level of around 85-90% in the storage environment helps:

- Prevent Drying: Ensures the poultry remains moist and prevents texture degradation.

- Reduce Oxidation: Minimises the risk of lipid oxidation, which affects flavor and shelf life.

Refrigeration units used in cold storage should be equipped with humidity controls to sustain these levels.

Storage Duration

The length of time poultry products can be stored without quality degradation varies:

- Fresh Poultry: Should be consumed or processed within 1-2 days when stored at optimal temperatures.

- Frozen Poultry: Remains safe for extended periods, typically up to 12 months, but optimum quality is retained when used within 6 months.

Labelling products with processing and expiration dates is recommended for effective inventory management and minimising waste.

Inventory Management

Effective inventory management strategies are essential in cold storage facilities:

- First-In-First-Out (FIFO): Ensures older stock is utilised before newer stock, reducing waste.

- Routine Inspections: Regular checks for signs of spoilage or improper storage conditions help maintain quality and safety.

Consistent monitoring and adherence to these principles ensure the integrity of poultry products from storage to consumption.

Cold storage of poultry involves meticulous management of various elements, each contributing to the overall safety and quality of the products stored. Proper techniques and active monitoring are crucial for keeping poultry in optimal condition.

The Importance of Temperature Control

Maintaining proper temperature control is crucial for preserving the quality and safety of poultry products in cold storage. Fluctuations in temperature can lead to bacterial growth, spoilage, and a reduction in shelf life. Several factors emphasise the need for stringent temperature management in cold storage facilities:

- Bacterial Growth Prevention: The growth of bacteria such as Salmonella and Campylobacter is significantly slowed down at lower temperatures. Ensuring a consistent temperature below 4°C (39.2°F) helps inhibit the proliferation of harmful pathogens.

- Quality Maintenance: Temperature variations can cause physical and chemical changes in poultry products. Maintaining a constant temperature prevents the degradation of texture, flavour, and nutritional value.

- Extended Shelf Life: By controlling the temperature effectively, the shelf life of poultry products can be extended. This reduces waste and ensures that consumers receive fresh products.

Key Temperature Guidelines

- Chilled Storage:

- Maintain temperatures between -1°C and 4°C (30.2°F to 39.2°F).

- Regular temperature checks should be conducted to ensure compliance.

- Frozen Storage:

- Keep temperatures at or below -18°C (0°F).

- Minimise temperature fluctuations to avoid freezer burn and maintain product quality.

Best Practices for Temperature Control

- Monitoring Systems: Install reliable temperature monitoring systems that provide real-time data and alerts for any deviations.

- Regular Maintenance: Ensure that cold storage equipment undergoes scheduled maintenance to prevent malfunctions that can compromise temperature control.

- Proper Loading and Stacking: Avoid overloading storage units and ensure proper air circulation to maintain uniform temperatures.

Temperature control in cold storage is essential not only for compliance with food safety regulations but also for consumer protection. Retailers, suppliers, and producers must adhere to these practices to maintain the integrity and safety of poultry products throughout the supply chain.

Ideal Humidity Levels for Poultry Products Cold Storage

The importance of maintaining ideal humidity levels in the cold storage of poultry products cannot be overstated. Incorrect humidity levels can lead to several undesirable outcomes, including spoilage, weight loss, and texture degradation. Here, the focus is placed on what specific humidity levels are appropriate and why they are significant.

Factors Influencing Humidity Levels

- Temperature: The ambient temperature in the storage facility directly impacts the humidity levels. Generally, colder temperatures are beneficial for slowing down bacterial growth but can reduce humidity.

- Airflow: Proper airflow is essential to ensure even humidity distribution. Inefficient airflow can cause dry spots, leading to uneven cooling and potential spoilage.

- Storage Time: Duration of storage affects the moisture content of poultry products. Longer storage times typically require more finely-tuned humidity controls to maintain quality.

Recommended Humidity Levels

- Raw Poultry: Humidity levels should be maintained between 85% and 90% to prevent drying out. This range helps retain moisture in the meat, ensuring that it remains juicy and tender upon cooking.

- Frozen Poultry: For frozen products, a lower humidity level of around 65% to 70% is recommended. While freezing significantly slows down bacterial growth, extremely low humidity can lead to freezer burn, affecting the texture and flavour.

- Processed Poultry: Products like deli meats and sausages typically require humidity levels around 75% to 80%. This balance helps maintain product integrity, flavour, and shelf life.

Tools for Humidity Control

Several tools and technologies are available to achieve and maintain the ideal humidity levels:

- Hygrometers: These devices are crucial for regular monitoring of humidity levels. Digital hygrometers provide highly accurate readings and can often be integrated into automated systems.

- Humidifiers and Dehumidifiers: Based on the readings from hygrometers, these machines can add or remove moisture from the air to maintain the optimal humidity levels.

- Sealed Packaging: Vacuum-sealed packaging can help retain the moisture content of poultry products, minimising the need for external humidity adjustments.

Challenges and Solutions

Some common challenges in maintaining ideal humidity levels include:

- Fluctuating Outdoor Conditions: Seasonal changes in ambient humidity can impact the internal conditions of storage facilities. Installing advanced climate control systems can help mitigate these fluctuations.

- Equipment Malfunction: Regular maintenance and calibration of hygrometers, humidifiers, and related equipment are essential to ensure they function correctly and consistently.

- Storage Density: Overcrowding in storage areas can obstruct airflow and lead to uneven humidity distribution. Appropriate spacing between stored products aids in maintaining uniform humidity.

Understanding and implementing these ideal humidity levels can significantly improve the shelf life, quality, and safety of poultry products in cold storage environments.

Packaging Strategies for Poultry Products Cold Storage

Packaging plays a crucial role in prolonging the shelf life of poultry products in cold storage. The choice of packaging materials and methods directly impacts the product’s quality, safety, and freshness. Several strategies can be employed to enhance the shelf life of these products.

Vacuum Packaging

Vacuum packaging involves removing air from the packaging before sealing. This method reduces oxygen levels, which can inhibit the growth of aerobic bacteria and spoilage organisms. The benefits include:

- Extended freshness: Preventing oxidation and spoilage.

- Enhanced safety: Reduction in the risk of contamination by aerobic pathogens.

- Better texture and colour: Maintenance of natural appearance and tenderness.

Modified Atmosphere Packaging (MAP)

Modified Atmosphere Packaging alters the composition of the internal atmosphere of the package, typically replacing oxygen with gases such as carbon dioxide and nitrogen. The advantages are:

- Protection against microbial growth: Reduced oxygen levels hinder aerobic bacteria.

- Extended shelf life: Optimized gas mixtures slow down the degradation process.

- Market appeal: Maintains product appearance and taste.

Active Packaging

Active packaging involves incorporating substances that interact with the product or its environment to improve shelf life. Common techniques include:

- Oxygen scavengers: Absorb excess oxygen inside the package.

- Moisture absorbers: Maintain optimal humidity levels to prevent spoilage.

- Antimicrobial agents: Reduce bacterial and fungal growth on the product surface.

Edible Coatings

Edible coatings can act as an additional barrier to moisture and oxygen, while being safe for consumption. Benefits include:

- Barrier to gases: Reduces moisture loss and exposure to airborne contaminants.

- Enhanced product safety: Can incorporate natural antimicrobial compounds.

- Improved sensory attributes: Often provides a more natural appearance and flavour.

High-Pressure Processing (HPP)

High-Pressure Processing is a pasteurisation method that uses high pressure rather than heat to kill bacteria. Key benefits include:

- Microbial inactivation: Effective against a broad range of pathogens.

- Retention of nutrients: Minimal impact on flavour and nutritional content.

- Shelf life extension: Extends freshness without the need for preservatives.

Smart Packaging

Smart packaging involves the use of sensors or indicators that provide information about the condition of the packaged food. Advantages encompass:

- Real-time monitoring: Tracks temperature variations and spoilage indicators.

- Consumer confidence: Provides information on product freshness and safety.

- Enhanced logistics: Assists in maintaining optimal storage conditions throughout the supply chain.

These packaging strategies can significantly contribute to extending the shelf life of poultry products, thereby ensuring their quality and safety during cold storage.

Monitoring and Maintaining Air Circulation

Effective air circulation is crucial for ensuring consistency in temperature and humidity throughout the cold storage area. Improper air flow can result in hot spots where temperature fluctuates, negatively affecting the quality and safety of poultry products.

Key Considerations for Air Circulation

- Even Distribution of Air:

- Utilise strategically placed fans to promote uniform airflow.

- Ensure no areas within the storage are cut off from air movement.

- Temperature Sensors:

- Install multiple temperature sensors at various locations and heights.

- Regularly monitor and calibrate sensors to detect and address discrepancies promptly.

- Obstruction Management:

- Avoid stacking poultry products in ways that obstruct airflow.

- Maintain adequate space between storage racks and walls for air movement.

Equipment and Maintenance

Fans and Ventilation Systems

- Type: Choose high-efficiency fans suitable for cold storage environments.

- Placement: Position fans to optimise airflow patterns and minimise stagnant zones.

- Maintenance: Clean and service fans and ventilation systems routinely to prevent blockages and inefficiencies.

Air Circulation Pathways

- Ensure the design of air circulation pathways minimises the risk of cross-contamination.

- Regularly inspect ducts and vents to ensure they are free of obstructions and in good working order.

Monitoring Strategies

- Routine Inspections:

- Schedule regular inspections of fans, ducts, and vents.

- Check for signs of wear and tear or blockages that could impede airflow.

- Digital Monitoring Systems:

- Implement digital monitoring systems for real-time tracking of air circulation.

- Use alerts and notifications to quickly address any issues.

- Adjustments and Calibration:

- Adjust fan speed and direction based on seasons and storage density.

- Regularly calibrate airflow systems to maintain optimal conditions.

Best Practices

- Training: Ensure all personnel are trained to understand the importance of proper air circulation.

- Documentation: Keep detailed records of all maintenance and monitoring activities.

- Emergency Plans: Develop and implement emergency plans for equipment failures or unexpected airflow disruptions.

Maintaining proper air circulation is vital for preserving the quality and safety of poultry products. Consistent monitoring and proactive maintenance are essential components in achieving optimal storage conditions.

Impact of Different Storage Methods on Quality

Various storage methods significantly impact the quality of poultry products. Understanding these impacts can aid in maintaining optimal freshness, flavour, and safety of the products.

Refrigeration vs. Freezing

- Refrigeration (0°C to 4°C):

- Slows down microbial growth but does not stop it entirely.

- Maintains moisture and texture relatively well.

- Short-term solution, typically up to 2 days for raw poultry.

- Freezing (<-18°C):

- Effectively halts microbial activity, extending shelf-life significantly.

- Can cause freezer burn if not properly packaged, affecting texture and taste.

- Optimal for long-term storage, potentially up to 12 months for raw poultry.

Packaging Techniques

- Vacuum Sealing:

- Removes air, reducing oxidation and spoilage.

- Maintains flavour, texture, and colour better by minimising exposure to oxygen.

- Modified Atmosphere Packaging (MAP):

- Replaces air in the packaging with a gas mix that slows down spoilage.

- Extends shelf-life by several days despite refrigeration temperatures.

- Airtight Containers:

- Limits air exposure, though not as effective as vacuum sealing.

- Practical for short-term storage and easy handling.

Humidity Control

- High Humidity:

- Maintains moisture levels in fresh poultry, preventing drying out.

- Ideal for non-frozen storage, typically around 85-90% humidity.

- Low Humidity:

- Reduces the risk of surface moisture which can foster bacterial growth.

- More suitable for frozen storage, preventing frost build-up.

Temperature Consistency

Maintaining consistent temperatures is crucial for preserving the quality:

- Fluctuating Temperatures:

- Can lead to partial thawing and refreezing, deteriorating texture and safety.

- Stable Temperatures:

- Ensures the integrity of the poultry product by preventing microbial growth and quality degradation.

Thawing Methods

The method of thawing frozen poultry also affects its quality:

- Refrigerator Thawing:

- Slow and controlled, minimising bacterial growth.

- Maintains texture and juiciness better than quicker methods.

- Cold Water Thawing:

- Faster than refrigerator thawing but requires caution to maintain water temperatures.

- Risk of water seepage affecting texture if packaging is compromised.

- Microwave Thawing:

- Fast but can lead to uneven thawing, affecting texture and taste.

- Best for immediate cooking to prevent bacterial growth during the thawing process.

Understanding the impact of different storage methods on poultry quality is essential for both food safety and maintaining product integrity.

Preventing Cross-Contamination in Poultry Products Cold Storage

Preventing cross-contamination in cold storage is crucial for maintaining the safety and quality of poultry products. Implementing strict hygiene and organisational practices can significantly reduce the risk of contamination.

Segregation of Products

- Store raw poultry products separately from ready-to-eat foods.

- Use physical barriers or designated storage areas to prevent accidental contact.

- Label and color-code containers to distinguish between different types of foods.

Storage Conditions

- Maintain a consistent temperature of -18°C (0°F) or lower for frozen poultry.

- Refrigerate poultry at 4°C (39°F) or below.

- Avoid temperature fluctuations to reduce bacterial growth and spoilage.

Handling and Packaging

- Ensure poultry products are fully sealed and leak-proof.

- Regularly check the packaging for damages and replace if compromised.

- Handle poultry with dedicated tools and equipment to avoid cross-contact.

Regular Cleaning and Disinfection

- Clean storage areas and equipment with approved disinfectants.

- Follow a strict cleaning schedule, focusing on high-contact surfaces.

- Use disposable or sanitized cloths to prevent the spreading contaminants.

Training and Awareness

- Educate staff on proper storage procedures and the risks of cross-contamination.

- Conduct regular training sessions on food safety and hygiene protocols.

- Display clear signage and guidelines within storage facilities.

Regular Inspections

- Perform routine inspections to ensure compliance with safety standards.

- Monitor and document storage conditions, including temperature logs.

- Identify and address any signs of contamination or poor practices promptly.

Ventilation and Air Circulation

- Maintain adequate air circulation to prevent moisture build-up.

- Use quality air filters to reduce airborne contaminants.

- Ensure proper airflow between products to avoid hotspots where bacteria can thrive.

Stringent adherence to these practices helps maintain the integrity and safety of poultry products within cold storage environments, ensuring they remain fit for consumption and free from harmful pathogens.

Best Practices for Inventory Management

Effective inventory management is crucial for maintaining the quality and safety of poultry products in cold storage. Proper procedures help in minimising waste, ensuring product freshness, and maintaining compliance with food safety regulations.

Inventory Rotation

- First-In, First-Out (FIFO): Implementing FIFO ensures older stock is used before newer stock, reducing the risk of spoilage.

- Date Labelling: Clearly label all products with the date of storage and expiration to facilitate FIFO.

- Regular Audits: Conduct inventory audits regularly to verify stock levels and condition.

Temperature Monitoring

- Constant Monitoring: Use automated systems to constantly monitor and log temperatures.

- Alarm Systems: Install alarm systems that alert staff to any deviations from optimal temperature ranges immediately.

- Calibrated Equipment: Ensure all thermometers and sensors are regularly calibrated for accuracy.

Hygiene and Sanitation

- Cleaning Schedules: Establish and adhere to rigorous cleaning schedules for all storage areas and equipment.

- Hygiene Protocols: Staff should follow strict hygiene protocols, including wearing appropriate protective clothing, to prevent contamination.

- Inspection Protocols: Regularly inspect storage conditions to detect and address any hygiene issues promptly.

Stock Forecasting

- Demand Analysis: Use historical data and market trends to forecast demand accurately and avoid overstocking or understocking.

- Supplier Relationships: Maintain strong relationships with suppliers to ensure reliable delivery schedules and stock levels.

- Inventory Software: Utilise inventory management software to track stock levels, forecast demand, and manage orders efficiently.

Staff Training

- Comprehensive Training: Train staff comprehensively on inventory management practices and the importance of maintaining cold chain integrity.

- Ongoing Education: Regularly update training programmes to incorporate the latest best practices and technological advancements.

- Role-Based Training: Tailor training programs to the specific roles of staff members to ensure relevance and effectiveness.

Documentation

- Record Keeping: Maintain detailed records of all inventory movements and storage conditions.

- Compliance Documentation: Ensure all documentation meets regulatory requirements for food safety and traceability.

- Audit Trails: Establish audit trails for traceability in the event of a recall or quality issue.

By implementing these best practices, businesses can ensure that poultry products are stored under optimal conditions, preserving quality and extending shelf life effectively. Adhering to these guidelines can significantly contribute to operational efficiency and food safety compliance.

Regular Inspection and Maintenance of Poultry Products Cold Storage Facilities

Regular inspection and maintenance of cold storage facilities are crucial for ensuring the optimal storage conditions for poultry products. These activities help in preventing equipment failures, maintaining the quality of stored products, and ensuring compliance with health and safety standards.

Key Aspects of Regular Inspection

- Temperature Checks:

- Regularly verify that the temperature within the storage unit remains within the prescribed range for poultry products.

- Use calibrated thermometers to ensure accuracy.

- Conduct both surface and core temperature checks of the stored products.

- Humidity Levels:

- Ensure that humidity levels are maintained within the required range to prevent spoilage or freezer burn.

- Regularly monitor and adjust humidity settings as needed.

- Structural Integrity:

- Inspect walls, ceilings, and floors for signs of wear, damage, or moisture build-up which could impact cooling efficiency.

- Ensure that doors and seals are intact and functioning properly to maintain optimal insulation.

Maintenance Protocols

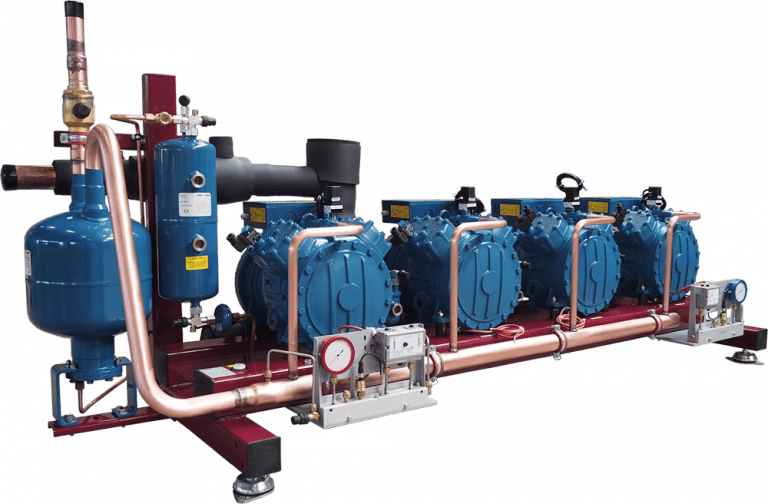

- Refrigeration Units:

- Schedule routine servicing of refrigeration units to prevent breakdowns.

- Clean and inspect condenser coils and evaporator units.

- Check for refrigerant leaks and ensure that refrigerant levels are adequate.

- Ventilation and Airflow:

- Periodically clean and inspect air circulation fans to ensure proper airflow.

- Verify that ventilation systems are free of obstructions and function effectively.

- Sanitation:

- Implement regular cleaning schedules for the facility, including thorough sanitisation of surfaces that come in contact with poultry products.

- Use food-safe cleaning agents to prevent contamination.

Best Practices

- Record Keeping:

- Maintain detailed records of all inspections, maintenance activities, and corrective actions taken.

- Ensure that these records are easily accessible for review during audits or inspections.

- Training:

- Provide ongoing training for staff on proper maintenance procedures and protocols.

- Ensure that staff are aware of how to identify and report potential issues.

- Emergency Preparedness:

- Develop and regularly update an emergency plan for equipment failures or power outages.

- Equip the facility with backup power sources and emergency contacts.

Continuous attention to these areas will help ensure that cold storage facilities operate efficiently and maintain the quality and safety of poultry products stored within.

Regulations and Standards for Poultry Products Cold Storage

Poultry cold storage must adhere to specific regulations and standards established by various health and safety organizations. These regulations ensure the safe storage of poultry products, thereby protecting consumer health.

Temperature Control

- Cold Storage Temperature: Poultry products must be stored at a temperature not exceeding -18°C (0°F) to prevent bacterial growth.

- Monitoring Systems: Regular monitoring of storage temperatures is mandatory to ensure consistent compliance with the required temperature limits.

Hygiene Standards

- Cleaning Protocols: Cold storage facilities must implement rigorous cleaning protocols, including regular sanitation of storage units, handling equipment, and transport vehicles.

- Contamination Prevention: Measures should be taken to prevent cross-contamination, such as segregating poultry products from other foods.

Packaging Requirements

- Material Standards: Packaging materials must be food-grade and suitable for cold storage to prevent the degradation of the packages and maintain product integrity.

- Labeling: All poultry packages must include clear labelling indicating the product type, storage conditions, and expiry date.

Handling Procedures

- Storage Practices: Poultry should be properly stored on pallets or shelves to allow adequate air circulation and avoid direct contact with the floor.

- Personnel Training: Staff must be trained in proper handling techniques to prevent contamination and ensure the maintenance of cold chain standards.

Compliance and Certification

- Inspection and Audits: Regular inspections and audits by health authorities ensure compliance with cold storage standards and regulations.

- Certification Requirements: Facilities may require certification, such as Hazard Analysis and Critical Control Points (HACCP), to validate their compliance with safety standards.

Government and International Standards

- Federal Guidelines: In the UK, compliance with the Food Standards Agency (FSA) guidelines is necessary for poultry cold storage facilities.

- International Standards: Facilities exporting poultry should adhere to international standards such as those set by the Codex Alimentarius Commission.

Record-Keeping

- Documentation: Facilities must maintain accurate records of temperature logs, cleaning schedules, and inspection reports.

- Traceability: Effective traceability systems should be in place to quickly identify and address any safety concerns.

Proper adherence to these regulations and standards ensures the safe storage of poultry products, preserves their quality, and protects consumer health.

Case Studies: Successful Poultry Products Cold Storage Implementations

Successful cold storage implementations for poultry products span a range of scenarios, each characterized by strategic planning and adherence to industry standards. This section examines notable examples.

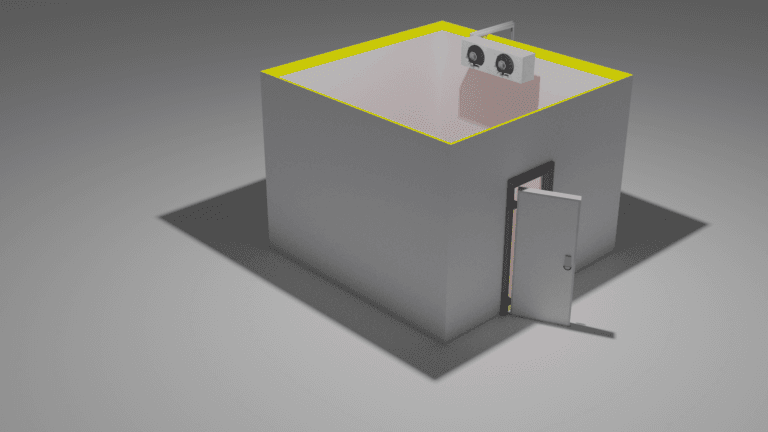

Case Study 1: Large-Scale Poultry Processing Facility

A large-scale poultry processing facility in the United States implemented state-of-the-art cold storage solutions to optimise their poultry product shelf life:

- Temperature Control: The facility maintained a consistent storage temperature of -18°C, crucial for preserving poultry quality over extended periods.

- Automated Systems: The integration of automated monitoring systems ensured real-time adjustments to temperature and humidity levels, preventing temperature deviations.

- Energy Efficiency: The use of energy-efficient refrigeration units reduced operational costs while maintaining necessary cold conditions.

These methods resulted in a notable reduction in product spoilage rates, demonstrating the effectiveness of stringent temperature management.

Case Study 2: Mid-Sized Poultry Farm

A mid-sized poultry farm in Europe adopted a hybrid cold storage strategy combining traditional and innovative approaches:

- Insulated Storage Areas: The farm utilised high-quality insulating materials to minimise thermal exchange, maintaining a stable internal environment.

- Dynamic Shelving: Adjustable shelving systems allowed better air circulation, ensuring uniform cooling across all poultry products.

- Monitoring and Data Analysis: Implementing IoT-based monitoring technology provided insights into storage conditions, helping the farm make data-driven decisions.

This approach enhanced the farm’s ability to maintain product quality and extend shelf life, leading to improved customer satisfaction.

Case Study 3: Large Retail Chain

A large retail chain in Asia successfully upgraded its cold storage facilities to better manage poultry inventory:

- Centralized Cooling System: The multi-storey storage facility used a central cooling system for efficient temperature distribution.

- Quick Freeze Technology: Utilising quick freeze mechanisms helped retain the natural texture and flavor of poultry products.

- Regular Audits: Routine quality audits ensured compliance with safety and health regulations.

This initiative resulted in significant reductions in poultry wastage and operational costs, highlighting the importance of regular audits and advanced technology.

Case Study 4: Small Local Butcher Shop

A small local butcher shop in Australia implemented cold storage improvements with a focus on quality and customer service:

- Compact Freezers: Custom-designed compact freezers allow precise temperature settings tailored to various poultry products.

- Regular Maintenance: Scheduled maintenance kept the refrigeration systems operating at peak efficiency.

- Employee Training: Staff received thorough training on best practices for handling and storing poultry.

The improvements led to enhanced freshness and longer shelf life for products, fostering customer trust and repeat business.

Conclusion

The success of these case studies underscores the critical role of technology, maintenance, and training in optimising cold storage conditions for poultry products. Adhering to industry standards and implementing modern solutions can significantly enhance product quality and operational efficiency.

Emerging Technologies in Poultry Products Cold Storage

Emerging technologies in poultry cold storage are revolutionizing how poultry products are preserved and transported. These advancements can enhance food safety, extend shelf life, and improve overall quality. The integration of such technologies into the poultry cold storage industry is becoming increasingly crucial.

1. Advanced Refrigeration Systems

- Variable Speed Compressors: These compressors adjust their speed based on cooling demand, thus offering greater energy efficiency and improved temperature control.

- Cryogenic Freezing: Utilises extremely low temperatures with liquid nitrogen or carbon dioxide, leading to faster freezing rates and better preservation of meat texture.

2. Smart Monitoring Systems

- IoT-Enabled Sensors: Internet of Things (IoT) sensors provide real-time monitoring of temperature, humidity, and other critical factors. Alerts can be sent if conditions deviate from optimal ranges, preventing spoilage.

- Remote Monitoring: Systems that allow operators to track storage conditions from anywhere using smartphones or computers, ensuring constant oversight and quick response to any issues.

3. Advanced Packaging Solutions

- Modified Atmosphere Packaging (MAP): Involves altering the atmosphere inside the packaging to slow microbial growth and oxidation, thereby extending shelf life.

- Active Packaging: Utilises materials that can interact with the contents, such as oxygen scavengers or antimicrobial agents to prevent spoilage and improve safety.

4. Blockchain Technology

- Traceability: Blockchain technology ensures transparency and traceability from farm to fork. Every step of the supply chain is recorded, providing assurance of product authenticity and quality.

- Temperature Loggers: Blockchain can integrate with temperature loggers to maintain a detailed and immutable record of storage conditions throughout the transportation process.

5. Energy-Efficient Storage Solutions

- Eco-Friendly Refrigerants: The adoption of refrigerants with lower global warming potential (GWP) is on the rise. These alternatives to traditional refrigerants help mitigate environmental impact.

- Thermal Energy Storage: Systems that store thermal energy when electricity prices are low and release it when prices are high, leading to cost savings and better energy management.

By adopting these emerging technologies, the poultry industry can advance in maintaining product quality, safety, and sustainability.

Conclusion and Recommendations

To ensure optimal storage conditions for poultry products in cold storage, the following recommendations should be adhered to:

- Temperature Control

- Maintain a constant storage temperature between -1°C and 4°C to slow bacterial growth and preserve quality.

- Use temperature monitoring systems to provide real-time temperature data and prevent fluctuations.

- Regularly calibrate thermometers and temperature sensors to ensure accuracy.

- Humidity Levels

- Maintain relative humidity between 85% and 90% to prevent moisture loss and minimise weight shrinkage.

- Utilise humidity control equipment such as humidifiers and dehumidifiers as necessary.

- Regularly check and record humidity levels to avoid microbial growth or desiccation.

- Air Circulation

- Ensure proper air circulation to maintain uniform temperature and humidity throughout the storage area.

- Avoid overloading storage rooms, which can obstruct airflow and lead to temperature inconsistencies.

- Position fans strategically to enhance airflow and reduce temperature gradients.

- Sanitation and Hygiene

- Implement strict sanitation protocols, including regular cleaning of storage areas and equipment.

- Use food-grade sanitizers to eliminate pathogens without contaminating the products.

- Assign staff to conduct regular inspections and audits of hygiene practices.

- Packaging

- Use appropriate packaging materials that provide an effective barrier against contamination and moisture loss.

- Vacuum-seal poultry products when possible to extend shelf life by reducing oxygen exposure.

- Clearly label packaged products with storage and handling instructions for better inventory management.

- Worker Training

- Train staff on best practices for handling and storing poultry products.

- Provide periodic refresher courses to keep staff updated on new technologies and protocols.

- Encourage open communication to quickly address any deviations or issues.

By following these guidelines, cold storage facilities can effectively maintain the quality and safety of poultry products.