Refrigeration Cycle

In simple terms, the task of a refrigeration cycle is heat absorption and heat rejection. As any HVAC instructor will tell you (definitely), you can’t catch a cold, you can just take the heat away. The refrigeration cycle, sometimes called the heat pump cycle, is a way of removing heat from the area you want to cool. This is accomplished by manipulating the pressure of the working coolant (air, water, synthetic coolants, etc.) through a compression and expansion loop. The system is generally used in cold storage, display cabinets, process cooling.

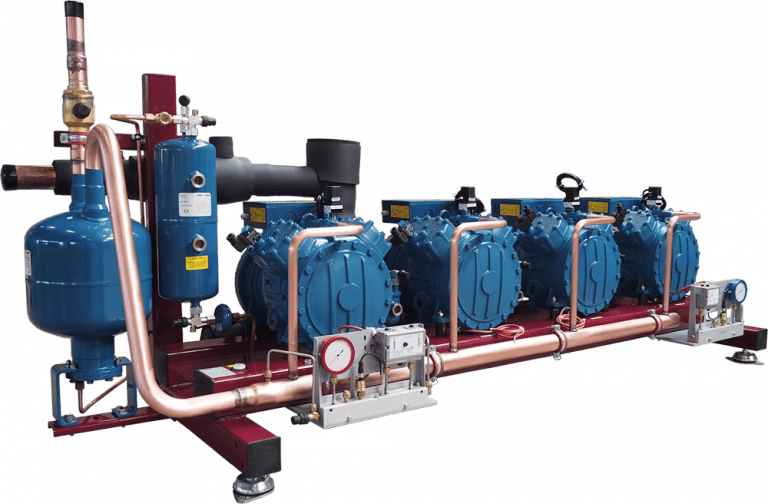

1-Refrigeration Cycle Component Refrigeration Compressor

Compression is the first step in the refrigeration cycle, and a compressor is the piece of equipment that increases the pressure of the working gas. Refrigerant enters the compressor as low-pressure, low-temperature gas, and leaves the compressor as a high-pressure, high-temperature gas.

Types of Refrigeration Compressors

Compression can be achieved through a number of different mechanical processes, and because of that, several compressor designs are used in HVAC and refrigeration today. Other examples exist, but some popular choices are:

- Reciprocating compressors

- Scroll compressors

- Rotary compressors

Required features in Refrigeration Compressor:

- Continuous capacity control and height change should be in accordance with the working regime.

- The torque must be low at first start-up.

- Efficiency should not decrease at partial loads

- It should maintain its safety and reliability in variable working conditions.

- It should not make much noise at partial and full loads under variable conditions.

- It must have a long life

- It should give more cooling with less power consumption

- It should be low cost

2 -Refrigeration Cycle Component Condenser

The condenser, or condenser coil, is one of two types of heat exchangers used in a basic refrigeration loop. This component is supplied with high-temperature high-pressure, vaporized refrigerant coming off the compressor. The condenser removes heat from the hot refrigerant vapor gas vapor until it condenses into a saturated liquid state, a.k.a. condensation. After condensing, the refrigerant is a high-pressure, low-temperature liquid, at which point it’s routed to the loop’s expansion device.

3-Refrigeration Cycle Component Expansion Valve

These components come in a few different designs. Popular configurations include fixed orifices, thermostatic expansion valves (TXV) or thermal expansion valves, and the more advanced electronic expansion valves (EEVs). But regardless of configuration, the job of a system’s expansion device is the same – create a drop in pressure after the refrigerant leaves the condenser. This pressure drop will cause some of that refrigerant to quickly boil, creating a two-phase mixture.

This rapid phase change is called flashing, and it helps tee up the next piece of equipment in the circuit, the evaporator, to perform its intended function.

4 -Refrigeration Cycle Component Evaporator

The evaporator is the second heat exchanger is a standard refrigeration circuit, and like the condenser, it’s named for its basic function. It serves as the “business end” of a refrigeration cycle, given that it does what we expect air conditioning to do – absorb heat.

This happens when refrigerant enters the evaporator as a low-temperature liquid at low pressure, and a fan forces air across the evaporator’s fins, cooling the air by absorbing the heat from the space in question into the refrigerant.

After doing so, the refrigerant is sent back to the compressor, where the process restarts. And that, in a nutshell, is how a refrigeration loop works.

*If you have any questions about the refrigeration cycle or its components and how they work, submit a request and we can discuss your company’s needs.