Mangoes, a beloved tropical fruit, undergo a natural ripening process that transforms them from firm and often sour to soft, sweet, and aromatic. In the industrial context, the uniform ripening of mangoes is crucial. Businesses strive for consistent quality and timing to meet market demand and ensure customer satisfaction. This process involves controlling various factors such as temperature, ethylene concentration, and humidity. Industrial mango ripening not only enables year-round availability of ripe fruit but also allows for extended storage and transport possibilities, making mangoes accessible globally and bolstering the agricultural economy.

Understanding the Natural Mango Ripening Process

Mangoes ripen naturally post-harvest during a process influenced by temperature and ethylene, a plant hormone. Here is what typically happens:

- Once plucked, mangoes produce ethylene, which acts as an internal signal that initiates the ripening process.

- Ethylene production leads to changes such as the breakdown of starches into sugars, thus increasing the fruit’s sweetness.

- Concurrently, acids are reduced, and enzymes soften the mango’s flesh.

- The skin transforms from green to vibrant yellow, red, or orange, and the fruit develops its characteristic flavor and aroma.

- Ideal temperatures for natural ripening generally range between 18°C and 24°C.

The process may vary slightly based on the mango variety and environmental conditions.

Ripening Agents Used in the Industrial Processing of Mangoes

To regulate the ripening process, the industry commonly uses ethylene gas. Ethylene, a natural plant hormone, is introduced in controlled environments to stimulate the ripening enzymes within the mangoes. Calcium carbide, though less favored due to health concerns, is another agent used by some processors. Additionally, ethephon—a synthetic version of ethylene—is sometimes applied as a liquid that releases ethylene gas upon contact with the mangoes’ surfaces. These agents promote uniform color development, softening, and the breakdown of complex sugars into simpler, sweeter ones. Nonetheless, strict monitoring is necessary to ensure consumer safety and optimal fruit quality.

Ethylene Gas: The Catalyst in Artificial Mango Ripening

Ethylene gas plays a crucial role in the industrial ripening of mangoes. This naturally occurring plant hormone, when used in a controlled environment, stimulates the ripening process, ensuring uniform softening and color development. Industrial ripening facilities introduce ethylene in a gas form to trigger the ripening of mangoes that have been picked while still firm. Ethylene’s efficacy as a ripening agent is attributed to its action at a biochemical level, where it enhances enzymatic activities that modify the fruit’s texture, flavor, and color.

- Ethylene prompts the degradation of chlorophyll, leading to the yellowing of mango peels.

- It accelerates the conversion of starches to sugars, enhancing sweetness.

- The gas influences the breakdown of acids, which mellows the fruit.

- Ethylene application must be carefully managed to ensure food safety and quality.

By harnessing ethylene, producers can achieve a more predictable and market-ready mango product.

Setting the Stage: Pre-Ripening Handling and Storage

The successful ripening of mangoes begins with proper handling and storage pre-ripening. Industry standards dictate:

- Harvested mangoes must be cooled immediately to slow down respiration and decay.

- Transport in ventilated containers to prevent ethylene accumulation and moisture loss.

- Sorting based on maturity ensures uniform ripening processes.

- Pre-ripening cold storage at appropriate temperatures is critical; typically between 13°C and 18°C.

- Relative humidity levels should be maintained at 85-90% to avoid dehydration and weight loss.

- Protection from ethylene-producing fruits and mechanical damage is essential.

Adhering to these protocols is crucial for preparing mangoes for the subsequent controlled ripening phase.

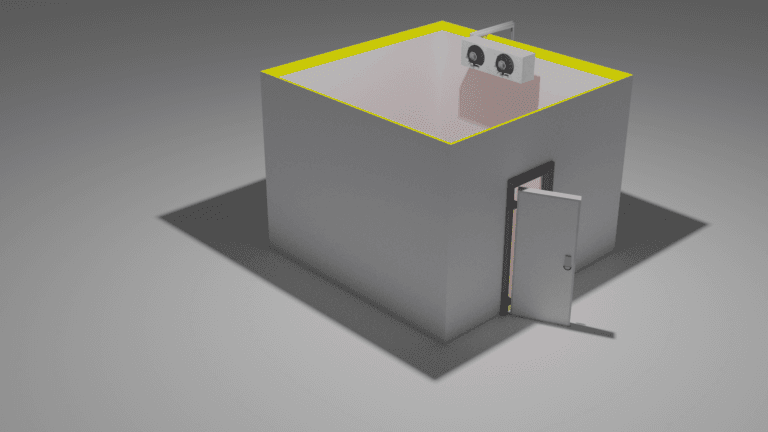

The Science of Mango Ripening Chambers: Controlled Environment Ripening

Ripening chambers offer a regulated environment for hastening the maturation of mangoes. These specialized rooms are designed to control factors such as temperature, humidity, and ethylene concentration. In a typical scenario:

- Temperature is maintained between 18°C to 22°C, ideal for mango ripening.

- Humidity levels are kept at 90-95%, preventing dehydration and maintaining fruit texture.

- Ethylene gas, a natural ripening agent, is introduced in controlled amounts to ensure uniform ripening.

The integration of these elements stimulates specific enzymatic reactions in the mangoes, promoting the breakdown of complex sugars and the development of characteristic flavor and color. Thus, creating uniformly ripe, market-ready mangoes.

Temperature and Humidity Control in Mango Ripening

Achieving the perfect ripeness in mangoes necessitates precise temperature and humidity control. The ripening process is often conducted at temperatures ranging from 18 to 22 degrees Celsius. Slightly warmer temperatures may expedite ripening, while cooler temperatures slow it down. Humidity levels are equally pivotal, with the optimal range being between 90% to 95%. These conditions prevent the fruit from losing moisture, thereby maintaining its juicy quality. Industrial ripening facilities utilize sophisticated equipment to maintain these conditions consistently, ensuring that the mangoes ripen uniformly and reach the market in peak condition.

Monitoring the Ripeness: The Role of Sensory Evaluation and Technology

To ensure optimal quality, the ripeness of mangoes is monitored through sensory evaluation and advanced technology. Sensory evaluation involves expert graders using sight, touch, and smell to assess fruit maturity. Essential attributes include:

- Skin color changes

- Firmness reduction

- Aroma development

In contrast, technology offers objective measurements. Examples include:

- Near-Infrared Spectroscopy (NIR) to detect chemical changes

- Ethylene sensors for ripeness-associated gas monitoring

- Pressure testing devices determining fruit softness

Together, these methods facilitate precise ripening control, crucial for consumer satisfaction and reducing waste.

Health and Safety Concerns: Chemicals and Consumables

Industrial mango ripening involves several chemicals such as ethylene, calcium carbide, and assorted growth regulators. Ethylene, a naturally occurring plant hormone, is generally recognized as safe when used appropriately. Yet, industrial-grade application necessitates careful handling and monitoring to prevent excessive inhalation. Calcium carbide, another ripening agent, can pose serious health risks, including skin and respiratory irritation. Unregulated use may result in arsenic and phosphorous, toxic to humans.

In dealing with these substances:

- Proper ventilation must be ensured to mitigate the risks of gas inhalation.

- Workers should implement personal protective equipment (PPE) like gloves and masks.

- Regular training on the safe handling of chemicals is vital.

- Storage and disposal of chemicals must comply with local environmental regulations.

Precautions and Best Practices to Ensure Fruit Quality and Safety

- Regularly inspect facilities for cleanliness and hygiene to prevent contamination.

- Implement a rigorous pest control program to protect against infestations.

- Train staff thoroughly in safe handling and ripening processes to maintain consistency.

- Utilize protective gear, such as gloves and masks, to safeguard against chemical exposure.

- Monitor the temperature and humidity levels closely to promote even ripening.

- Use ethylene gas responsibly and store it away from combustion sources.

- Conduct periodic maintenance of ripening equipment to ensure proper functioning.

- Keep a detailed record of ripening batches for traceability in case of food safety incidents.

- Source high-quality fruits from reputable suppliers to ensure superior end products.

- Always adhere to local and international food safety standards to assure consumer confidence.

Environmental Impacts and Sustainability Considerations

Industrial mango ripening involves several environmental and sustainability issues:

- Ethylene Production: The synthesis of ethylene, a ripening agent, contributes to greenhouse gas emissions. Minimizing leakage and using eco-friendlier alternatives are essential.

- Energy Use: Ripening chambers require considerable energy. Implementing energy-efficient systems reduces carbon footprints.

- Water Consumption: Water is used for cleaning fruit and facilities. Employing water-saving techniques is important.

- Waste Management: Disposal of non-ripe or overripe mangoes can lead to food waste. Creating efficient distribution systems can mitigate this.

- Packaging Materials: The use of plastics or non-recyclable materials in packaging impacts landfills. Opting for biodegradable or recyclable options aids sustainability.

- Transportation: Shipping ripe mangoes has implications for fossil fuel use and pollution. Localized ripening centers can help in reducing transportation emissions.

Regulatory Framework and Compliance in the Mango Ripening Industry

The mango ripening industry is governed by stringent regulations to ensure food safety and quality. Compliance involves:

- Adhering to local and international food safety standards such as ISO and HACCP.

- Using only approved ripening agents like ethylene at safe concentrations.

- Implementing record-keeping systems to track ripening agents used.

- We are ensuring worker safety through proper training and use of protective equipment.

- Regular inspection and certification by food safety authorities.

- Environmental regulations, including proper waste management and emission controls.

Operators must navigate these regulatory landscapes to avoid legal penalties and maintain consumer trust.

Advancements and Innovations in Mango Ripening Technology

The domain of mango ripening has embraced several technological advancements:

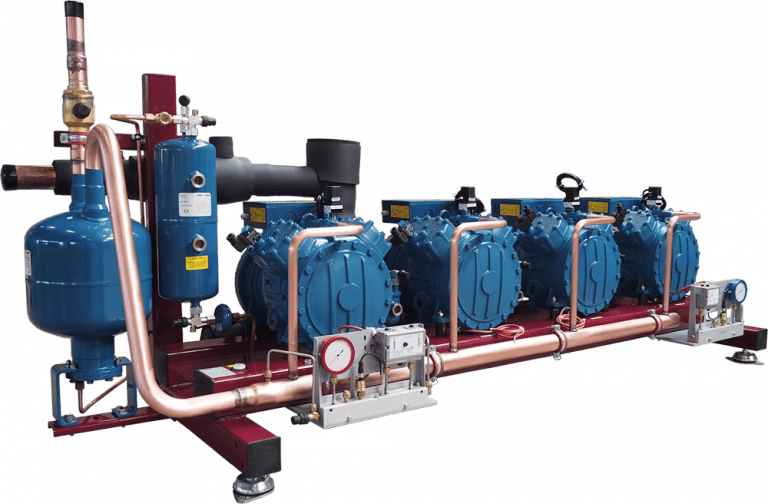

- Ethylene Generators: Improved devices now offer precision in ethylene release, crucial for uniform mango ripening.

- Smart Ripening Chambers: Incorporating sensors and microprocessors, these chambers adjust temperature and humidity dynamically.

- Non-Chemical Treatments: Alternatives like hot water treatments and UV radiation are gaining traction as safer ripening methods.

- Data Analytics: Use of AI and machine learning to predict and enhance ripening schedules and outcomes.

These innovations contribute to increased efficiency, safety, and fruit quality in industrial mango ripening.

The Future of Mango Ripening: Trends and Predictions

Advancements in the mango ripening process are expected to be driven by sustainability and technology adoption. Key trends and predictions include:

- Integration of IoT: Sensors and IoT devices will allow for real-time monitoring, enabling precise control over temperature and ethylene concentrations during ripening.

- AI and Machine Learning: These technologies will refine ripening algorithms, resulting in consistent quality and reduction of spoilage.

- Eco-Friendly Practices: There will be a shift towards more natural ripening agents and recyclable ripening chambers.

- Traceability: Blockchain technology will enhance traceability, allowing consumers to verify the ripening process and origin.

- Robotics: Automated sorting and handling of mangoes will minimize damage and improve efficiency.

Such innovations are poised to transform mango ripening into a more efficient, sustainable, and consumer-transparent process.

Conclusion: The Balance Between Efficiency and Natural Quality

Achieving equilibrium in industrial mango ripening is paramount. Industry professionals must juggle efficiency and scale whilst honoring the natural ripening process. Ethylene application, when scientifically managed, can mirror nature, yet safeguards are vital to prevent over-manipulation. Ultimately, consumer health and sensory experience must guide practices. Striking this balance is key to commercial success and maintaining integrity in how we deliver nature’s bounty.