Are you in the market for industrial cold room doors? Whether you’re setting up a new cold storage facility or upgrading an existing one, choosing the right doors is crucial for maintaining temperature control, energy efficiency, and overall operational effectiveness. In this comprehensive guide, we’ll explore everything you need to know about industrial cold room doors, from their types and features to maintenance and safety considerations.

Understanding Industrial Cold Room Doors

Industrial cold room doors are specialized entryways designed to maintain the temperature and humidity levels inside cold storage facilities. These doors play a vital role in preserving perishable goods, preventing energy loss, and ensuring smooth operations in various industries, including food processing, pharmaceuticals, and logistics.

The Importance of Quality Cold Room Doors

Investing in high-quality industrial cold room doors is essential for several reasons:

- Temperature control: They help maintain consistent temperatures inside the cold room, preventing fluctuations that could compromise product quality.

- Energy efficiency: Well-insulated doors reduce energy consumption by minimizing heat transfer between the cold room and the outside environment.

- Hygiene: Many cold room doors are designed with materials that are easy to clean and resistant to bacterial growth, crucial for food safety.

- Durability: Industrial-grade doors can withstand frequent use and harsh conditions, reducing maintenance costs over time.

Types of Industrial Cold Room Doors

There are several types of industrial cold room doors available, each suited to different applications and requirements. Let’s explore some of the most common options:

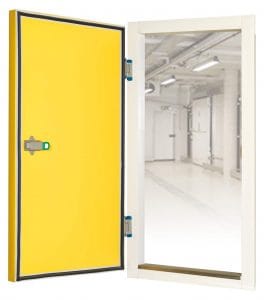

Hinged Doors

Hinged cold room doors are similar to traditional doors but with added insulation and sealing properties. They’re a popular choice for smaller cold rooms and areas with less traffic.

- Pros: Cost-effective, easy to install, and suitable for pedestrian access.

- Cons: Require more space to open and close, which may not be ideal for busy environments.

industrial hinged cold room door

Sliding Doors

Sliding cold room doors are designed to move horizontally along a track. They’re excellent for larger openings and areas where space is at a premium.

- Pros: Space-saving, easy to operate, and ideal for high-traffic areas.

- Cons: May require more maintenance due to moving parts and tracks.

Industrial Sliding Cold Room Door

High-Speed Doors

High-speed industrial cold room doors are designed for environments where quick opening and closing are essential. They help maintain temperature control in high-traffic areas.

- Pros: Minimize air exchange, improve energy efficiency, and increase productivity.

- Cons: Higher initial cost and may require specialized maintenance.

Key Features to Consider

When selecting industrial cold room doors, pay attention to these important features:

Insulation

The insulation quality of your cold room doors directly affects energy efficiency and temperature control. Look for doors with high R-values, which indicate better insulation properties.

Sealing Mechanisms

Effective seals around the door edges prevent air leakage and maintain the cold room’s integrity. Options include magnetic seals, gaskets, and brush seals, depending on the door type.

Safety Features

Safety should be a top priority when selecting industrial cold room doors. Look for features such as:

- Emergency release mechanisms

- Impact-resistant construction

- Anti-slip flooring near door areas

- Proper lighting and visibility features

Maintenance and Care

Regular maintenance of your industrial cold room doors is crucial for ensuring their longevity and optimal performance. Here are some tips:

- Inspect seals and gaskets regularly for wear and tear.

- Clean door surfaces and tracks frequently to prevent buildup of dirt and ice.

- Lubricate moving parts as recommended by the manufacturer.

- Check and adjust door alignment periodically.

- Address any issues promptly to prevent more significant problems.

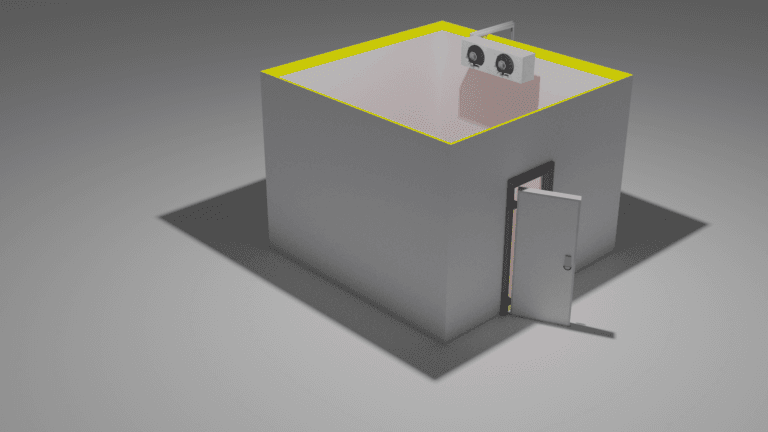

Choosing the Right Door for Your Facility

Selecting the best industrial cold room doors for your facility depends on various factors:

- Room size and layout

- Traffic patterns and frequency

- Types of products stored

- Industry-specific regulations

- Budget considerations

It’s always advisable to consult with a professional who can assess your specific needs and recommend the most suitable options.

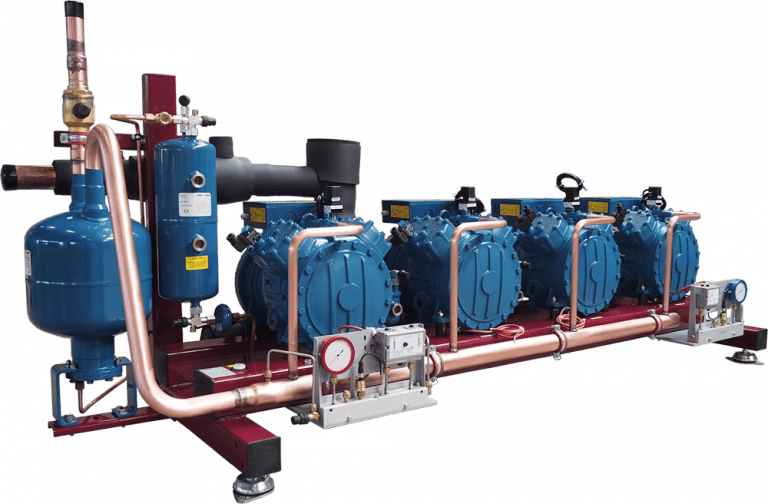

Energy Efficiency and Cost Savings

Investing in high-quality industrial cold room doors can lead to significant energy savings over time. Energy-efficient doors help reduce the workload on refrigeration systems, leading to lower electricity costs and a smaller carbon footprint.

Did you know? Some studies suggest that up to 30% of a cold room’s energy loss can occur through poorly insulated or maintained doors.

Consider doors with features like automatic closing mechanisms or air curtains to further enhance energy efficiency.

Conclusion

Industrial cold room doors are a critical component of any cold storage facility. By choosing the right type of door with appropriate features and maintaining it properly, you can ensure optimal temperature control, energy efficiency, and operational effectiveness.

Remember, the best industrial cold room doors are those that meet your specific needs while complying with industry standards and regulations. Take the time to research and consult with experts to make an informed decision that will benefit your business in the long run.

Whether you’re in food processing, pharmaceuticals, or any industry requiring cold storage, investing in quality industrial cold room doors is a decision that will pay off in improved operations, energy savings, and product quality.