From homes to hospitals and food processing to pharmaceuticals, cooling systems are fundamental to modern society. Refrigeration serves a critical function: it slows the activity of bacteria, thus reducing the spoilage of food, it maintains the efficacy of medicines and keeps our environments at comfort levels. The need for cooling stems from the basic requirement to preserve products and provide habitable conditions, regardless of external temperatures.

Consider that before refrigeration, preserving food was a complex challenge, often dictating dietary patterns and seasonal availability. Without the ability to cool and store food, much would go to waste, and entire supply chains would be less efficient. In medicine, without chilled storage, many lifesaving vaccines and drugs would degrade rapidly. In the world of computers and electronics, components generate heat and without proper cooling, would quickly fail.

- Food Preservation: Slowing down the growth of microorganisms and enzymes that cause food to spoil.

- Medical and Pharmaceutical Storage: Keeping critical medical supplies and medications at stable temperatures to ensure potency and efficacy.

- Comfort and Productivity: Providing cool environments that enhance human comfort and increase productivity in workplaces.

- Electronics and Machinery Cooling: Preventing overheating in electronics and machinery, which can lead to malfunctions or decreased efficiency.

- Industrial Processes: Numerous industrial processes rely on cooling to maintain the integrity of products and materials.

At its core, refrigeration deals with transferring heat from a place where it is undesirable to a place where its presence is inconsequential. This mechanism not only ensures the longevity and utility of various products but also enhances the quality of life in many aspects. With this understanding of the need for refrigeration, we can delve into the scientific principles that make these cooling processes possible.

Historical Developments in Refrigeration Technology

The journey to modern refrigeration technologies started with rudimentary methods such as the use of ice and snow to preserve food. However, the scientific advancements that underpin today’s refrigeration cycle have come a long way:

- Artificial Refrigeration Begins: The first known artificial refrigeration system was demonstrated by William Cullen at the University of Glasgow in 1748, but it wasn’t practical for everyday use. Cullen’s experiments laid the foundation for understanding the principles of gas evaporation and condensation.

- Compression Cycle: Michael Faraday’s work in the 1820s on the liquefaction of gases contributed significantly to refrigeration. This led to the invention of a practical vapor compression cycle by Jacob Perkins in 1834, which is the basis for many modern refrigeration systems.

- Widespread Adoption: As understanding of the vapor compression cycle improved, so did the technology. In the late 19th century, Carl von Linde’s work was critical in developing reliable refrigeration systems, primarily for the brewing and meat-packing industries, leading to broader commercial adoption.

- Domestic Refrigeration: The 20th century saw the development of electric domestic refrigerators. Frigidaire introduced the first self-contained unit in 1923, forever transforming food storage in homes.

- Technological Advancements: Throughout the 20th century, advancements have included the shift to more environmentally friendly refrigerants due to the recognition of the harmful effects of substances like CFCs on the ozone layer. Improvements in efficiency, size, and cost have also characterized this period.

- Modern Innovations: In the 21st century, the focus has been on digital technologies that enhance energy efficiency and user convenience, along with the integration of refrigeration systems into smart home ecosystems.

Historical milestones in refrigeration technology have revolutionized how we preserve food, deliver medical supplies, and maintain comfortable living and working environments. The persistent innovation in this field is a testament to the ingenuity and human desire to harness and control the fundamental principles of thermodynamics.

Fundamentals of Thermodynamics in Cooling Systems

Thermodynamics plays a pivotal role in the operation of cooling systems, which fundamentally rely on the principles of heat transfer and the laws of thermodynamics to function. Understanding the core concepts is essential to grasp how cooling systems, such as refrigerators and air conditioners, remove heat from one area and discharge it into another, ultimately achieving the desired cooling effect.

- First Law of Thermodynamics: Also known as the law of energy conservation, it states that energy cannot be created or destroyed in an isolated system. In cooling systems, this principle is observed as the refrigerant absorbs heat from the inside of a refrigerator (or the room in the case of an air conditioner) and then releases it outside. Energy, in this case thermal energy, is conserved and merely transferred from one place to another.

- Second Law of Thermodynamics: This law focuses on the concept of entropy, an indication of disorder within a system. It indicates that heat naturally flows from an object at a higher temperature to an object at a lower temperature. Cooling systems effectively reverse this natural heat flow by using work (often through a compressor), moving heat from cooler interiors to the warmer exterior environment.

- Refrigerant Cycle: The refrigerant, a substance with a low boiling point, is the lifeblood of a cooling system. As it circulates through the system, it undergoes various phase changes—evaporating to absorb heat (endothermic process) and condensing to release heat (exothermic process). The cycle’s effectiveness depends on the properties of the refrigerant and the efficiency of the system components.

- Heat Exchangers: Components such as evaporators and condensers act as heat exchangers. In the evaporator, the refrigerant absorbs heat and evaporates, cooling the surrounding area. The compressor then increases the pressure and temperature of the gaseous refrigerant, driving it to the condenser, where it releases its absorbed heat and changes back to a liquid.

By harnessing these thermodynamic principles, cooling systems perform the seemingly magical task of transferring heat against its natural direction, thereby maintaining our food, spaces, and industrial processes at desired temperatures.

Components of the Refrigeration Cycle: A Detailed Look

The refrigeration cycle is a sophisticated process involving several key components, each performing specialized functions to remove heat from an enclosed area and expel it to the surroundings.

- Compressor: At the heart of the cycle lies the compressor. This vital component is responsible for compressing the refrigerant, which raises the refrigerant’s temperature and pressure. As the main driver of the cycle, the compressor moves the refrigerant through the system.

- Condenser Coils: After leaving the compressor, the high-pressure hot refrigerant gas moves to the condenser coils. Here, it releases its heat to the outside air. As the refrigerant loses heat, it transforms from a gas into a liquid. This conversion is critical for the continuation of the cooling process.

- Expansion Valve: The liquid refrigerant then flows through the expansion valve, where it undergoes a sudden pressure drop. This rapid expansion cools the refrigerant substantially, preparing it for its entry into the evaporator at a low temperature and pressure.

- Evaporator Coils: Inside the evaporator coils, the chilled refrigerant absorbs heat from the refrigerator’s interior space or another designated area. As it absorbs heat, it evaporates, turning back into a low-pressure gas.

- Refrigerant: The substance that carries heat through this cycle is the refrigerant. It has properties that allow it to change state at convenient temperatures.

- Accumulator or Receiver: Depending on the system design, an accumulator or receiver may be present. These elements store excess refrigerant and prevent liquid refrigerant from entering the compressor, which could cause damage.

The orchestration of these components is what constitutes the refrigeration cycle, a continuous loop that maintains the desired cool temperature within a space. Each part ensures the refrigerant effectively transitions through various states of pressure and temperature, essential for the system’s operation.

The Role of Refrigerants in Heat Transfer

Refrigerants are the lifeblood of any refrigeration or air conditioning system. They facilitate the essential process of heat transfer, which is at the heart of cooling technology. The refrigerant’s primary purpose is to absorb and release heat as it circulates within the system.

During the refrigeration cycle, a refrigerant constantly changes its state between liquid and vapor. When a refrigerant evaporates into a gas within the system’s evaporator coil, it absorbs heat from the surrounding environment. This heat absorption causes the space being cooled—whether it’s a refrigerator, an air-conditioned room, or an industrial system—to lose heat and therefore cool down.

The refrigerant, now in gaseous form and laden with absorbed heat, travels to the compressor. Here, it is compressed, raising its pressure and temperature even further. The compressor effectively squeezes the refrigerant, preparing it for the next phase of the cycle.

Following compression, the hot gaseous refrigerant moves through the condenser coils. As the refrigerant passes through the coils, it releases the heat it previously absorbed into the outside environment. Air or water flowing over the condenser coils assists in removing the heat from the refrigerant. As the refrigerant cools down, it undergoes a phase change back to a liquid state.

The high-pressure liquid refrigerant then travels to the expansion valve. The valve depressurizes the refrigerant, cooling it rapidly before it re-enters the evaporator and begins the cycle anew.

It’s important to select the appropriate refrigerant for a given application considering its thermodynamic properties, environmental impact, and compatibility with the system components. Common refrigerants include hydrofluorocarbons (HFCs), chlorofluorocarbons (CFCs), and more recently, hydrocarbons and natural refrigerants like ammonia and carbon dioxide, which have lower environmental impacts. The refrigerant’s efficiency directly impacts the efficiency of the entire cooling system, positioning it as a critical factor in both energy consumption and climate control technology.

Exploring the Four Key Phases of the Refrigeration Cycle

The refrigeration cycle is a continuous and closed-loop process essential for cooling systems such as air conditioners and refrigerators. This cycle involves four key phases: evaporation, compression, condensation, and expansion.

- Evaporation: The refrigeration cycle begins in the evaporator with a low-pressure liquid refrigerant absorbing heat from its surrounding environment. As the refrigerant absorbs heat, it changes state from a liquid to a vapor. This phase change cools down the interior of the refrigerator or the room in case of an air conditioner.

- Compression: Next, the vaporized refrigerant is drawn into a compressor. In this phase, the compressor increases the pressure of the refrigerant vapor, raising its temperature. The high-pressure, high-temperature vapor then moves to the condenser.

- Condensation: Upon reaching the condenser coils, the hot refrigerant vapor releases the absorbed heat to the surroundings, usually the air outside the unit. As it loses heat, the refrigerant transitions from a gaseous state back into a liquid. This process is critical as it allows the refrigerant to expel the heat taken from inside the cooled space.

- Expansion: Finally, the high-pressure liquid refrigerant passes through an expansion valve or device, where it experiences a pressure drop. This sudden reduction in pressure cools the refrigerant further, causing it to partially evaporate and cool down before returning to the evaporator to begin another cycle.

Understanding these four phases of the refrigeration cycle elucidates how thermal energy is transported from one area to another, creating a cooling effect that is crucial in many modern applications. The cycle is a marvel of thermodynamics, embodying the principles of heat transfer and phase changes, and is fundamental to the design of efficient refrigeration and air conditioning systems.

Compression: Increasing Refrigerant Pressure and Temperature

Compression is a critical step in the refrigeration cycle that involves increasing the pressure and temperature of the refrigerant. Once the refrigerant has absorbed heat from the interior of the refrigerator or air-conditioned space during evaporation, it transitions to a state of low-pressure gas. The next stage is to prepare the refrigerant for heat release, and this is where the role of the compressor comes into play.

The compressor, often driven by an electric motor, takes in the low-pressure gaseous refrigerant and compresses it to a high-pressure state. As the refrigerant gas is compressed, the molecules are forced closer together which causes an increase in energy and thus raises the refrigerant’s temperature.

Here’s a breakdown of what happens during the compression phase:

- Intake of Refrigerant: The compressor sucks in the low-pressure gaseous refrigerant from the evaporator.

- Compression: Through mechanical action, the compressor reduces the volume available for the refrigerant, increasing its pressure.

- Temperature Rise: The pressure increase is directly proportional to the temperature increase, following the gas laws.

- Discharge: The now high-pressure, high-temperature gas is pushed out of the compressor towards the condenser.

The temperatures and pressures achieved during compression are substantially higher than the temperature outside the refrigeration system. This is fundamental as it allows for the subsequent release of the absorbed heat to the external environment in the condenser.

Not only does the compressor increase pressure and temperature, but it also maintains the refrigerant’s flow through the cycle, driving the continuous process that facilitates cooling. The efficiency of the compressor can have a significant impact on the overall efficiency of the refrigeration system; thus, advancements in compressor technology continue to be a focus for energy-saving improvements.

Condensation: Releasing Heat to the External Environment

In the refrigeration cycle, condensation plays a crucial role as a heat-releasing process. As refrigerant vapor, carrying heat absorbed from inside the refrigerator flows through the condenser coils, it encounters a lower-temperature environment. This external environment is where the refrigerant releases its heat.

When the gaseous refrigerant passes through the condenser coils, it is exposed to cooler outside air or water in some systems. This change in temperature causes the refrigerant to transition from its gaseous form back into a liquid state, a process known as condensation. Here’s the underlying science:

- The condenser operates at a pressure where the temperature of the refrigerant is higher than the external environment.

- As the heat flows out from the refrigerant to the external environment, the refrigerant loses its energy.

- The refrigerant coils facilitate the heat transfer efficiently. Often, the coils have fins that increase their surface area, enhancing the release of heat.

- Cooling fans or water are used to maintain the temperature gradient necessary for efficient heat transfer.

This release of heat to the external environment is an exothermic process and is essential for the refrigerant to continue its journey through the cycle effectively. It allows the refrigerant to once again absorb heat from the refrigerator’s interior, repeating the cycle.

Importantly, the efficiency of the condensation process affects the overall effectiveness of the refrigeration system. Poor heat release due to a dirty condenser or inadequate airflow/water flow can lead to a less efficient refrigeration cycle, higher energy consumption, and increased wear on the system components.

In essence, the condensation stage maintains the continuity of the refrigeration cycle by preparing the refrigerant for its next phase – expansion and absorption of heat, which occurs in the evaporator. Without this vital heat release, the system would not be able to sustain the cycle that keeps the refrigerator’s contents cool.

Expansion Devices: Controlling the Refrigerant Flow

In the intricate dance of the refrigeration cycle, one critical component responsible for controlling refrigerant flow is the expansion device. This device is pivotal in reducing the pressure of the refrigerant, which in turn cools it down and prepares it for the next crucial phase: entering the evaporator.

There are several types of expansion devices, each with its unique mechanisms and applications. The most common include:

- Thermostatic Expansion Valves (TXVs): These valves adjust the flow of refrigerant based on the evaporator’s temperature and the refrigerant’s superheat level. By sensing these variables, TXVs can regulate refrigerant flow with precision and efficiency.

- Capillary Tubes: Unlike TXVs, capillary tubes are simply fixed orifices. They rely on a pressure drop created by the small diameter and length of the tube to control the flow of refrigerant into the evaporator.

- Automatic Expansion Valves (AXVs): AXVs keep a constant superheat by adjusting the refrigerant flow based on pressure in the evaporator.

- Electronic Expansion Valves (EXVs): These are controlled by electronic controllers that precisely meter the refrigerant flow based on the cooling load and other system parameters.

These expansion devices are critical to ensuring the refrigerant exchanges heat effectively in the evaporator. By controlling the amount of refrigerant that enters the evaporator, expansion devices ensure the system operates efficiently and the desired temperature is maintained within the refrigerated space.

The selection of an appropriate expansion device is based on system size, the refrigerant type used, and the required level of control. Professional installation and calibration are essential for the optimal performance of these devices in the refrigeration cycle.

Evaporation: Absorbing Heat from the Surroundings

Evaporation is a fundamental process in the refrigeration cycle, crucial for absorbing heat from the environment to provide cooling. It involves a refrigerant, typically in liquid form, which absorbs heat and changes its state to a gas. This phase transition occurs at low pressure, which allows the refrigerant to vaporize at a lower temperature than it would at atmospheric pressure.

The science behind evaporation in refrigeration hinges on the properties of the refrigerant and the laws of thermodynamics. When the liquid refrigerant receives heat from its surroundings, typically from the air or a surface within a refrigerator or air conditioning system, it does so by absorbing that energy. This energy absorption increases the kinetic energy of the refrigerant’s molecules, breaking the intermolecular forces that hold the liquid together, thus causing a phase change into a gaseous state.

This energy transfer has an impressive cooling effect for several reasons:

- Latent Heat of Vaporization: A large amount of heat is absorbed from the surroundings during the refrigerant’s phase change, due to the high latent heat of vaporization. This is the energy required to turn a liquid into a gas without increasing its temperature.

- Lowered Boiling Point Under Reduced Pressure: By maintaining a lower pressure in the evaporator section of the refrigeration system, the boiling point of the refrigerant is decreased, allowing for heat absorption at lower temperatures.

- Continuous Cycle: In a closed system, the gaseous refrigerant is then compressed and cooled back into a liquid, releasing the absorbed heat elsewhere, before returning to the evaporator to repeat the cycle.

Through this method, a refrigeration system can effectively remove heat from an enclosed space and expel it to the exterior, thus lowering the temperature within the cooled space and maintaining it at a desired level. The evaporation step is vital for this continuous cycle of cooling, harnessed effectively in refrigeration and air conditioning systems worldwide.

The Refrigeration Cycle in Action: From Household to Industrial Use

The refrigeration cycle is a fundamental process that applies across different scales, from small household refrigerators to large industrial cooling systems. This marvel of thermodynamics allows for the precise control of temperature environments, essential for food preservation, air conditioning, and specialized industrial processes.

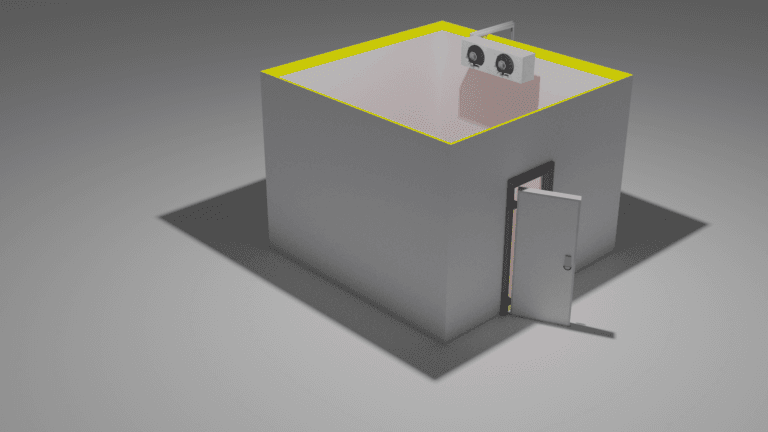

Household Refrigeration

In household units, the process begins with a compressor, which condenses refrigerant vapor, raising its pressure and temperature. The hot, pressurized gas then flows through condenser coils, losing heat to the surroundings. As the refrigerant cools, it transitions from a gas to a liquid.

The liquid refrigerant, now at a high pressure but lower temperature, reaches a thermal expansion valve or capillary tube. This device restricts flow, causing a pressure drop and cooling the refrigerant further. The cooled, expanded liquid then passes through the evaporator coils within the fridge or freezer compartment. Here, the refrigerant absorbs heat from the interior, effectively lowering the temperature. The resulting vapor is then sucked back into the compressor, and the cycle repeats.

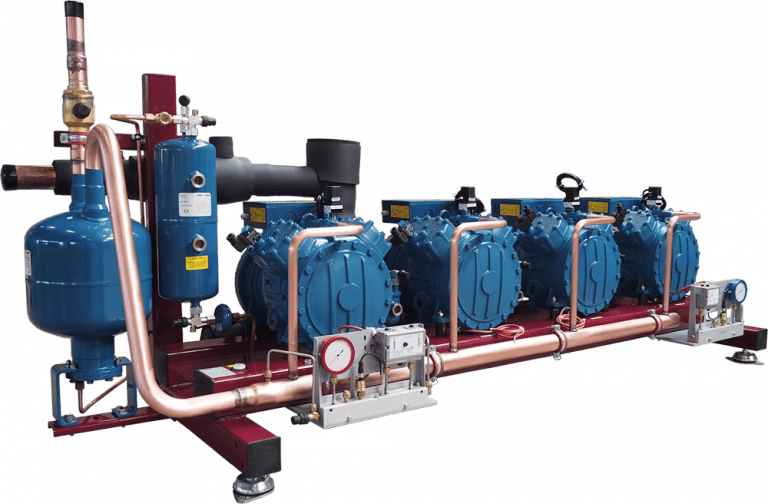

Industrial Cooling

Industrial systems follow the same basic principles but are designed for much larger-scale operations. Instead of a simple expansion valve, industrial refrigeration might employ sophisticated electronic expansion valves that precisely control the refrigerant flow to match cooling demand. The evaporator section in industrial units often encompasses vast chambers or is integrated within processes for the direct cooling of products or materials.

Furthermore, industrial cooling systems often incorporate multiple compressors working in stages or in parallel to handle large heat loads. Some systems recover and repurpose waste heat, improving energy efficiency — an increasingly important consideration for large facilities. Advanced monitoring and control systems are typically used to ensure that the refrigeration cycle operates optimally and reliably in these complex environments.

In every application, the refrigeration cycle is an exemplar of practical thermodynamics, transforming our ability to preserve, comfort, and manufacture with controlled cooling solutions.

Energy Efficiency and Performance Metrics in Refrigeration Systems

Understanding energy efficiency and performance metrics is crucial to evaluating and improving refrigeration systems. These metrics assist manufacturers and consumers in benchmarking the effectiveness and environmental impact of different refrigeration appliances. Here are the key indicators:

- Coefficient of Performance (COP): This is the ratio of the refrigeration effect produced to the energy consumed by the entire system over the same period. A higher COP indicates a more efficient refrigeration system.

- Energy Efficiency Ratio (EER): Similar to COP, EER is the ratio of the output cooling energy (in British Thermal Units, BTU) to electrical input energy (in watts) during steady-state operation. It’s typically used for rating room air conditioners.

- Seasonal Energy Efficiency Ratio (SEER): This metric measures the cooling output over a typical cooling season divided by the total electric energy input. A higher SEER rating means greater efficiency and, hence, lower operating costs.

- Total Equivalent Warming Impact (TEWI): It measures the overall global warming impact of a refrigeration system, taking into account the direct emissions of refrigerants and indirect emissions from energy consumption.

- Annual Energy Consumption: This straightforward measure indicates the total energy used by the appliance in a year, is useful for cost calculations.

An energy-efficient refrigeration system minimizes energy consumption without compromising performance, leading to lower operating costs and reduced environmental impact. Advances in technology and design, such as improved insulation materials, variable speed compressors, and eco-friendly refrigerants, have significantly enhanced these performance metrics, allowing consumers to make informed choices based on the energy efficiency and ecological footprint of their refrigeration systems.

Maintaining Your Refrigeration System: Best Practices

Ensuring the longevity and optimal performance of a refrigeration system goes beyond understanding how it works; regular maintenance is key. To prevent breakdowns and maintain energy efficiency, one should adopt a strategic approach.

- Inspect Refrigeration Seals Regularly: Worn seals can cause air to escape, forcing the system to work harder and consume more energy. Check for wear and tear, and replace the seals if they are not tight.

- Keep the Coils Clean: Dust and debris on the condenser and evaporator coils can restrict airflow and insulate the coils, reducing their ability to absorb and release heat. Clean these coils regularly to prevent these issues.

- Monitor Refrigerant Levels: Low refrigerant levels can hamper the efficiency of the cooling cycle, causing the system to overwork and leading to potential breakdowns. Ensure that refrigerant levels are checked and topped up by a professional as required.

- Check for Leaks: Refrigerant leaks not only affect performance but can also have environmental impacts. Have a technician test for and repair any leaks immediately.

- Maintain Correct Temperature: Overloading the system or setting the temperature lower than necessary can increase energy consumption and strain the components. Keep the temperature settings as recommended for the specific application.

- Schedule Regular Professional Inspections: Professional technicians can detect issues that may not be apparent to the untrained eye, allowing for preemptive maintenance and repairs.

- Clean and Replace Air Filters: Clogged air filters restrict airflow, causing strain on the system. Regular cleaning or replacement of air filters is essential for the system to function effectively.

Implementing these practices will result in better performance, reduced energy usage, and an extended lifespan for the refrigeration system. It is the responsibility of owners and operators to ensure their cooling equipment receives the attention it requires for continual, efficient operation.

Innovations and Future Technologies in Cooling

As the refrigeration cycle remains a vital component in modern cooling systems, continuous innovation is driven by the rising demands for energy efficiency and sustainability. Among the emerging technologies transforming the cooling industry are:

- Magnetic refrigeration: Employing magnets for a cooling effect, this technology uses the magnetocaloric effect to generate refrigeration without refrigerants that contribute to global warming, promising a significant reduction in energy consumption.

- Thermoacoustic cooling: This technique uses sound waves to create cooling, and it is known for having fewer moving parts, which may reduce maintenance requirements and improve reliability, all while being environmentally benign.

- Solid-state refrigeration: Solid-state technology utilizes the Peltier effect, where passing an electric current through a junction of two different metals can absorb heat. This leads to cooling without the need for traditional refrigerants or compressors, offering a quieter, more compact solution.

- Evaporative cooling with ionized water: A novel method that employs ionized water to enhance evaporative cooling. The ionization process can improve the cooling effect while also offering antibacterial and air purification benefits.

- Phase-change materials (PCMs): PCMs absorb and release thermal energy during the process of melting and freezing, providing opportunities for passive cooling strategies within buildings or in the development of more efficient cooling systems.

Researchers are also exploring the application of artificial intelligence in optimizing the efficiency and performance of cooling systems. From adaptive control systems that respond in real-time to fluctuations in demand to predictive maintenance that anticipates and prevents system failures, AI has the potential to reshape how cooling systems operate.

As these technologies develop, they herald a new era for cooling systems, expanding the potential for more sustainable, efficient, and effective climate control solutions.

The Environmental Impact of Refrigeration and Sustainable Alternatives

The traditional refrigeration cycle, while effective for cooling, carries a notable environmental burden. Refrigerants commonly used in these systems, such as chlorofluorocarbons (CFCs) and hydrofluorocarbons (HFCs), are potent greenhouse gases. When leaked into the atmosphere, they contribute significantly to global warming. Moreover, the energy consumption required for the refrigeration process often comes from non-renewable sources, further exacerbating carbon emissions.

- CFCs and HFCs have a global warming potential thousands of times greater than carbon dioxide.

- Improper disposal of refrigeration appliances can release these gases into the atmosphere.

- The energy-intensive nature of conventional cooling contributes to the emission of greenhouse gases from power plants.

In response to these issues, sustainable alternatives have emerged:

- Natural Refrigerants: Substances like ammonia, carbon dioxide, and hydrocarbons have a much lower environmental impact than traditional refrigerants.

- Magnetic Refrigeration: An emerging technology using the magnetocaloric effect to cool materials without harmful gases.

- Thermoelectric Cooling: Utilizes the Peltier effect, allowing for cooling through electricity without refrigerants.

- Absorption Refrigerators: Use heat, rather than electricity, as their primary energy source, which can be derived from renewable sources like solar power.

- Energy Efficiency Measures: Improved insulation, energy-efficient components, and smart systems that adapt cooling power to actual needs reduce overall energy consumption.

Replacing or supplementing traditional refrigeration systems with these alternatives can mitigate environmental impact while maintaining or even improving efficiency. Embracing these options is crucial for a sustainable future, as the demand for cooling continues to grow. The refrigeration industry must continue to innovate and integrate eco-friendly practices to preserve environmental health.

Common Problems and Troubleshooting Tips for Refrigeration Systems

Refrigeration systems, while essential in many sectors, can encounter a variety of issues that impede their efficiency and functionality. Addressing these common problems promptly can ensure the prolonged performance of the system. Below are some typical issues and steps for troubleshooting:

1. Inadequate Cooling

- Look for blockages or dirt in the condenser coils.

- Check if the evaporator fan is functioning properly.

- Verify that the thermostat is set correctly and functioning.

2. Strange Noises

- Identify the source of the noise – it could be from the compressor, fans, or defrost timer.

- Ensure no loose parts or obstructions are causing the noise.

- If rattling, confirm that the unit is leveled and all panels are screwed tight.

3. Frost Build-up or Excess Condensation

- Check the door seals for leaks allowing warm air to enter.

- Inspect the defrost system (timer, heater, and thermostat) for malfunctions.

- Verify proper airflow through the unit; blocked vents can cause condensation.

4. Increased Energy Consumption

- Ensure the condenser and evaporator coils are clean and free of debris.

- Confirm that the door gasket seals tightly with no tears or warping.

- Check that the refrigeration system isn’t oversized for the required cooling load.

5. Refrigerant Leaks

- Look for signs of oil residue around connections, which could indicate a leak.

- Use a refrigerant leak detector or soapy water to find small leaks.

- Ensure all connections are tight and repair any leaks promptly.

Troubleshooting these common problems can help to maintain the effectiveness of refrigeration systems. If the issue persists after attempting these solutions, it may be time to consult a professional technician with expertise in refrigeration to diagnose and resolve the complications.

Conclusion: The Importance of the Refrigeration Cycle in Modern Society

The refrigeration cycle, an essential marvel of engineering, breathes life into numerous facets of modern society, often in ways that go unnoticed by the general populace. Its paramount role extends well beyond food preservation and climate control, though these are critical for our day-to-day comfort and sustenance.

- Food Safety and Preservation: By slowing bacterial growth, refrigeration extends the shelf life of perishable goods, dramatically decreasing food wastage and ensuring a consistent food supply. This is pivotal for public health, reducing the incidence of foodborne illnesses and enabling a diverse diet year-round.

- Medical and Pharmaceutical Preservation: The cycle is critical in medicine, where vaccines, blood transfusions, and various medications require strict temperature control to remain effective, saving countless lives.

- Industrial Applications: Many industrial processes rely on the refrigeration cycle for material preservation, precise temperature control in manufacturing, or even in the cooling of equipment to prevent overheating, thereby maintaining our industrial and technological advancement.

- Comfort and Productivity: Air conditioning, made possible by the refrigeration cycle, has facilitated comfortable living and working environments. This, in turn, has been shown to increase human productivity and enhance the quality of life, particularly in regions with extreme climates.

- Scientific Research: Advanced scientific endeavors, ranging from environmental studies to particle physics, often depend on precise cooling systems integral to the integrity and success of experiments.

In conclusion, the refrigeration cycle is a cornerstone technology that has become indispensable in our daily lives. It supports a wide array of services and sectors, fostering health, comfort, and progress. The intricate dance of heat exchange and phase changes that power refrigeration systems is a testament to human ingenuity and a building block for continued advancements in technology and quality of life.